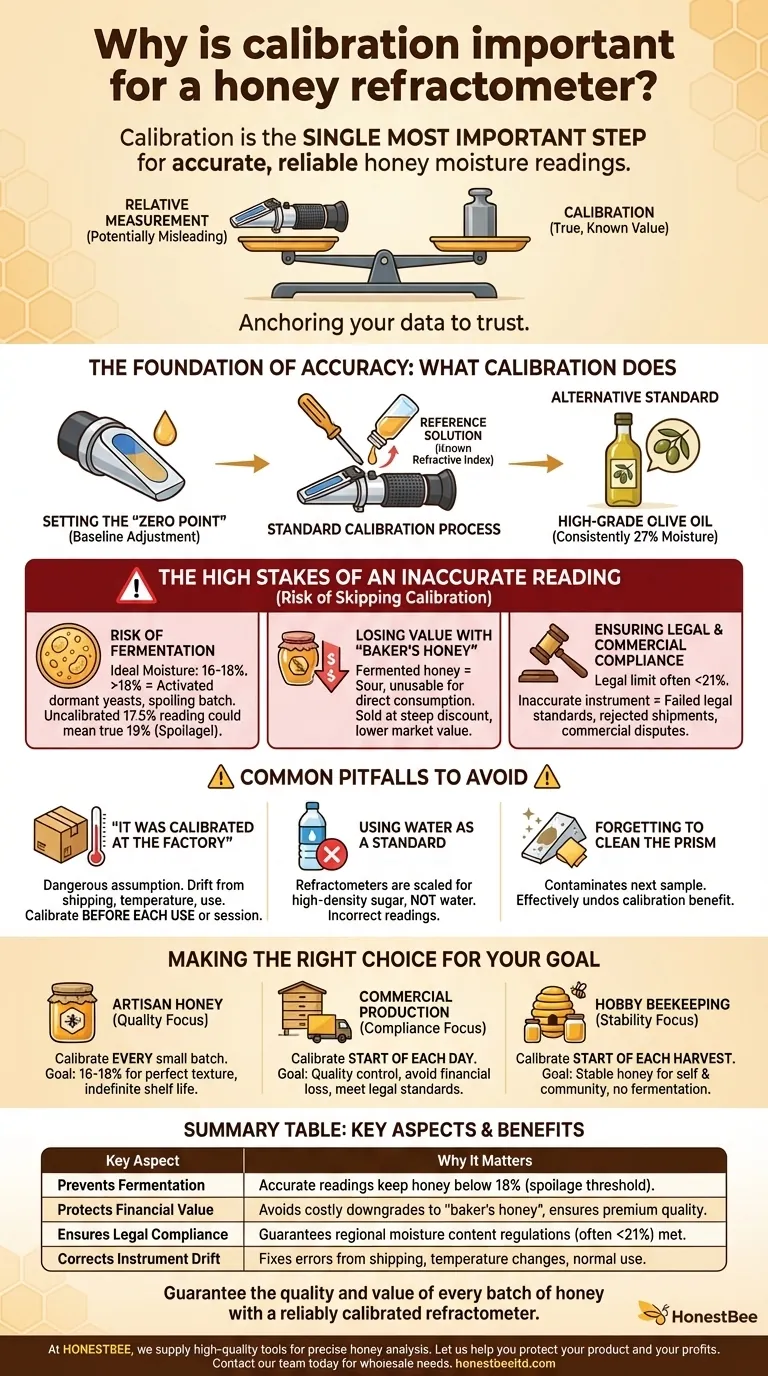

Calibration is the single most important step in using a honey refractometer. It is the process of adjusting the instrument against a known standard to ensure the readings it provides are accurate and reliable. Without proper calibration, any measurement of honey's moisture content is fundamentally untrustworthy.

Your refractometer only provides a relative measurement. Calibration is what anchors that measurement to a true, known value, turning a potentially misleading number into a definitive data point you can trust to protect your honey's quality and value.

The Foundation of Accuracy: What Calibration Actually Does

Calibration isn't an optional check; it is the procedure that makes your instrument a valid scientific tool. It corrects for any drift or error that may be present.

Setting the "Zero Point"

Think of a weighing scale. Before you weigh anything, you press the "tare" button to set it to zero. Calibration does the same for your refractometer, establishing a correct baseline. It adjusts the internal scale so that when it measures a substance with a known value, it displays that exact value.

The Standard Calibration Process

Most honey refractometers come with a small vial of a reference solution, often a specific type of oil. This liquid has a known, stable refractive index that corresponds to a specific moisture content, which will be printed on the vial.

To calibrate, you place a drop of this solution on the prism, take a reading, and use the included small screwdriver to adjust the calibration screw until the reading on the scale matches the value on the reference vial.

Using an Alternative Standard

If you lose the reference solution, high-grade olive oil is a widely accepted substitute. Olive oil consistently corresponds to a 27% moisture reading on a honey refractometer scale and can be used to reliably set your instrument's baseline.

The High Stakes of an Inaccurate Reading

Skipping calibration may save you thirty seconds, but it introduces enormous risk. An inaccurate reading directly leads to poor decisions with significant financial and quality consequences.

The Risk of Fermentation

The ideal moisture content for honey is between 16-18%. Above this level, dormant yeasts naturally present in the honey can activate and begin to ferment the sugars, spoiling the batch. If your uncalibrated refractometer reads 17.5% but the true value is 19%, you will extract and bottle honey that is destined to spoil.

Losing Value with "Baker's Honey"

Fermented honey is sour and often unusable for direct consumption. It is typically downgraded and sold at a steep discount as "baker's honey," which has a significantly lower market value. Proper calibration is a direct defense against this financial loss.

Ensuring Legal and Commercial Compliance

To be legally sold as honey in many regions, the product must have a moisture content below a specific threshold, often around 21%. An inaccurate, uncalibrated instrument could lead you to bottle a batch that fails to meet this legal standard, resulting in rejected shipments and commercial disputes.

Common Pitfalls to Avoid

Trusting a measurement device requires understanding its limitations and common points of failure. Calibration is the primary defense against these issues.

"It Was Calibrated at the Factory"

This is a dangerous assumption. Mechanical shock during shipping, temperature fluctuations, and even regular use can cause the instrument's calibration to drift. You must calibrate the device before each use or, at a minimum, at the start of each testing session.

Using Water as a Calibration Standard

Do not use distilled water to calibrate a honey refractometer. These devices are designed and scaled for measuring high-density sugar solutions, not water. Calibrating to water's zero point will result in incorrect readings for honey.

Forgetting to Clean the Prism

After each measurement, the prism and daylight plate must be wiped clean with a soft, damp cloth. Any leftover honey or calibration fluid will contaminate the next sample and render the reading inaccurate, effectively undoing the benefit of calibration.

Making the Right Choice for Your Goal

Integrating calibration into your workflow is simple and non-negotiable. It is the first step in any measurement process, not the last.

- If your primary focus is high-quality artisan honey: Calibrate before every small batch to guarantee the optimal 16-18% moisture content for perfect texture and indefinite shelf life.

- If your primary focus is commercial production and compliance: Calibrate at the start of each day as a mandatory quality control step to protect against financial loss and ensure every shipment meets legal standards.

- If your primary focus is hobby beekeeping: Calibrate at the start of each harvest session to ensure the honey you bottle for yourself and your community is stable and will not ferment.

Proper calibration transforms your refractometer from a simple gadget into a reliable instrument for guaranteeing the quality and stability of your final product.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Prevents Fermentation | Accurate readings ensure honey stays below 18% moisture, the threshold where spoilage begins. |

| Protects Financial Value | Avoids costly downgrades to "baker's honey" by ensuring product meets premium quality standards. |

| Ensures Legal Compliance | Guarantees your honey meets regional moisture content regulations (often below 21%) for sale. |

| Corrects Instrument Drift | Regular calibration fixes errors caused by shipping, temperature changes, and normal use. |

Guarantee the quality and value of every batch of honey with a reliably calibrated refractometer.

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, durable tools needed for precise honey analysis. Proper equipment is the foundation of accurate calibration and trustworthy results.

Let us help you protect your product and your profits. Contact our team today to discuss your wholesale needs for refractometers and other essential beekeeping supplies.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Digital Honey Refractometer for Precision Measurement of Optimal Honey Quality

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Portable Uncapping Tank Holder Uncapping Bench for Beekeeping

People Also Ask

- How is a manual refractometer used to determine honey quality? Essential Moisture Control for Commercial Beekeeping

- Why is a laboratory benchtop refractometer essential for honey? Secure Stability & Quality

- What should be considered regarding the measurement range of a honey refractometer? Ensure Peak Honey Quality

- What is the function of a honey refractometer in beekeeping? Ensure Harvest Quality and Prevent Fermentation

- What is the principle and importance of using a refractometer for honey moisture? Ensure Quality & Prevent Fermentation