The primary reason food-grade stainless steel is recommended for honey filling machines is its unique ability to protect the honey's purity. It is chemically non-reactive, resists corrosion from honey's natural acidity, and provides a smooth, easy-to-clean surface, all of which prevent contamination and ensure food safety compliance.

Choosing the right material for honey equipment is not merely a suggestion; it is a critical decision to safeguard the product's quality. Honey's natural properties can degrade or contaminate it if it comes into contact with the wrong materials, making food-grade stainless steel the definitive professional standard.

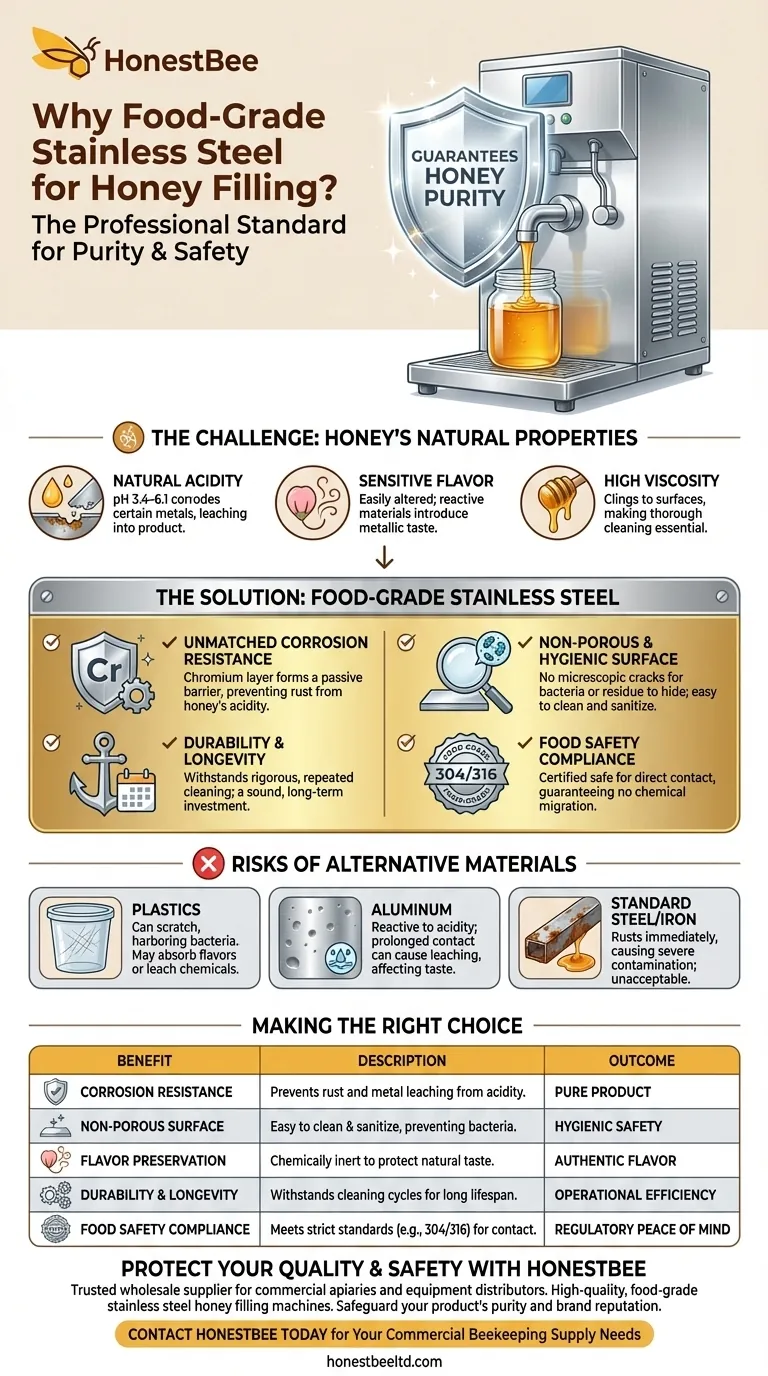

The Unique Challenge of Handling Honey

Before understanding the solution, it's crucial to recognize the specific properties of honey that make material selection so important. Honey is not an inert substance, and its composition presents distinct challenges for processing equipment.

Honey's Natural Acidity

Honey is naturally acidic, typically with a pH between 3.4 and 6.1. This acidity can cause a chemical reaction with certain metals, causing them to corrode and leach into the product.

Preserving Purity and Flavor

The flavor profile of honey is delicate and easily altered. Any material that reacts with the honey can introduce a metallic taste or other off-flavors, permanently compromising the quality of the batch.

The Demands of Viscosity

As a thick, viscous liquid, honey clings to surfaces. This makes thorough cleaning essential to prevent the buildup of residue that can harbor bacteria and spoil subsequent batches.

Why Food-Grade Stainless Steel is the Solution

Food-grade stainless steel directly addresses each of the challenges presented by honey. Its specific properties make it the ideal material for any surface that comes into contact with the product.

Unmatched Corrosion Resistance

The key to stainless steel is its chromium content, which forms a passive, non-reactive layer on the surface. This layer acts as a barrier, preventing honey's natural acids from causing rust or oxidation that would contaminate the product.

A Non-Porous and Hygienic Surface

The surface of stainless steel is extremely smooth and non-porous. This means there are no microscopic cracks or crevices where honey residue or bacteria can hide, making it exceptionally easy to clean and sanitize effectively.

Durability and Longevity

Honey processing equipment must withstand rigorous, repeated cleaning cycles. Stainless steel is a highly durable material that will not scratch, chip, or degrade over time, representing a sound, long-term investment.

Compliance with Food Safety Standards

The designation "food-grade" (such as types 304 or 316 stainless steel) certifies that the material is safe for direct contact with consumables. It guarantees that no harmful chemicals will migrate from the equipment into the honey.

The Risks of Using Alternative Materials

Understanding why stainless steel is the right choice also involves recognizing the clear disadvantages of other common materials.

Plastics

While some food-grade plastics exist, they can scratch easily. These scratches can become breeding grounds for bacteria that are difficult to remove. Certain plastics can also absorb flavors or leach chemicals over time.

Aluminum

Aluminum is a reactive metal that can corrode when in prolonged contact with acidic substances like honey. This can lead to aluminum leaching into the product, affecting both its safety and its taste.

Standard Steel or Iron

Using standard, non-stainless steel is not an option. It would begin to rust almost immediately upon contact with honey, causing severe contamination and rendering the product completely unsalable.

Making the Right Choice for Your Goal

When selecting your honey filling equipment, the material choice directly impacts your final product and the efficiency of your operation.

- If your primary focus is product safety and compliance: Demand certified food-grade stainless steel to ensure you meet all regulatory standards and protect your customers.

- If your primary focus is preserving honey's pure, natural flavor: The non-reactive, inert nature of stainless steel is non-negotiable to prevent any metallic or chemical tainting.

- If your primary focus is operational efficiency and longevity: The durability and ease of cleaning stainless steel will minimize downtime, prevent product loss, and guarantee your equipment lasts for years.

Ultimately, investing in food-grade stainless steel equipment is a direct investment in the quality, safety, and reputation of your honey.

Summary Table:

| Key Benefit | Description |

|---|---|

| Corrosion Resistance | Prevents rust and metal leaching from honey's natural acidity. |

| Non-Porous Surface | Easy to clean and sanitize, preventing bacterial growth. |

| Flavor Preservation | Chemically inert to protect honey's delicate, natural taste. |

| Durability & Longevity | Withstands rigorous cleaning cycles for a long equipment lifespan. |

| Food Safety Compliance | Meets strict standards (e.g., 304/316 stainless) for safe food contact. |

Protect the quality and safety of your honey products with HONESTBEE.

As a trusted wholesale supplier for commercial apiaries and beekeeping equipment distributors, we provide high-quality, food-grade stainless steel honey filling machines designed for durability, compliance, and operational efficiency. Our equipment safeguards your product's purity and your brand's reputation.

Contact HONESTBEE today to discuss your commercial beekeeping supply needs and discover the right equipment for your operation.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Automated Rotary Bottle Unscrambler for Honey Production Line

People Also Ask

- What core processing challenges are addressed by automated honey-filling machines? Boost Your Honey Production Now

- How do automated honey filling machines contribute to honey quality? Elevate Your Brand with Precision Automation

- How are the finished honey sticks separated and discharged from the machine? Streamline Your Honey Packaging Workflow

- What production challenges are addressed by high-precision honey filling machines? Optimize Your Honey Deep Processing

- How does automatic honey filling and processing equipment contribute to the integrity of organic honey production?

- What technical advantages do automated honey-filling machines offer? Boost Your Honey Production Efficiency Today

- How do automated honey filling machines ensure consistency and cleanliness? Precision Tech for 375ml to 1kg Containers

- What role do automated honey-filling machines play in overcoming market access barriers? Scale Your Forest Honey Sales