For beekeepers, uncapping wax is more than just a step in honey extraction—it’s a delicate balance between efficiency and preservation. Done right, it ensures maximum honey yield while keeping combs intact for future use. Done poorly, it can lead to wasted honey, damaged combs, and even stress on your bee colony. This guide dives into the science, tools, and techniques that make uncapping wax a seamless part of your beekeeping workflow.

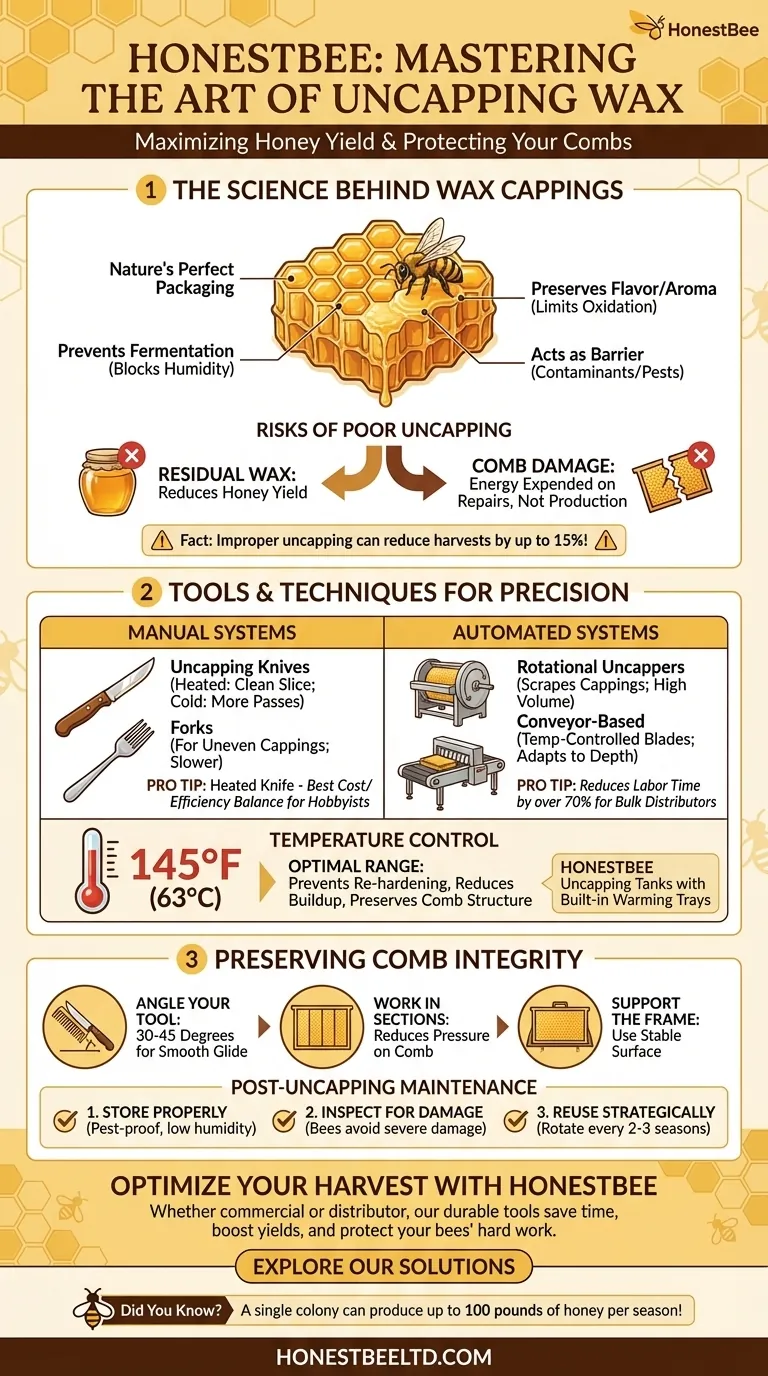

The Science Behind Wax Cappings

How Beeswax Seals Protect Honey Quality

Beeswax cappings are nature’s perfect packaging. Bees secrete wax to seal honeycomb cells once the honey reaches optimal moisture content (typically around 17–18%). This seal:

- Prevents fermentation by blocking external humidity

- Preserves flavor and aroma by limiting oxidation

- Acts as a barrier against contaminants like dust or pests

Research shows that honey stored under intact cappings can retain quality for years, making proper uncapping critical to avoid compromising these benefits.

Risks of Incomplete or Damaging Uncapping

Rushing the uncapping process can backfire in two ways:

- Residual Wax: Leaving even small amounts of cappings on combs reduces honey yield during extraction.

- Comb Damage: Aggressive tools (e.g., blunt knives or forks) tear comb cells, forcing bees to expend energy on repairs instead of honey production.

A study of small-scale apiaries found that improper uncapping can reduce harvests by up to 15%—a significant loss for commercial operations.

Tools and Techniques for Precision Uncapping

Manual vs. Automated Uncapping Systems

Manual Tools:

- Uncapping Knives: Heated knives (electric or steam-powered) slice through wax cleanly, minimizing residue. Cold knives require more passes, increasing comb damage risk.

- Forks: Best for salvaging uneven cappings but slower and less efficient for large batches.

Automated Systems:

- Rotational Uncappers: Used in industrial settings, these machines gently scrape cappings via rotating blades or brushes, processing hundreds of frames per hour.

- Conveyor-Based Systems: Pair with temperature-controlled blades to adapt to varying comb depths.

Pro Tip: For hobbyists, a heated knife strikes the best balance between cost and efficiency. For distributors handling bulk orders, automated systems reduce labor time by over 70%.

Temperature Control to Minimize Wax Residue

Wax melts at around 145°F (63°C). Tools that maintain this range:

- Prevent wax from re-hardening mid-process

- Reduce sticky buildup on equipment

- Preserve comb structure by avoiding excessive heat exposure

HONESTBEE’s uncapping tanks with built-in warming trays help beekeepers recycle dripping wax and honey efficiently.

Preserving Comb Integrity for Sustainable Beekeeping

Balancing Speed and Delicacy in Extraction

Fast uncapping isn’t always better. To protect combs:

- Angle Your Tool: Hold knives at 30–45 degrees to glide smoothly under cappings.

- Work in Sections: Uncapping one side of a frame first reduces pressure on the comb.

- Support the Frame: Use a stable surface to avoid bending or cracking mid-process.

Post-Uncapping Comb Maintenance Tips

After extraction, combs need care to stay reusable:

- Store Properly: Keep frames in a pest-proof container with low humidity.

- Inspect for Damage: Bees avoid repairing severely damaged combs, leading to uneven rebuilding.

- Reuse Strategically: Rotate combs every 2–3 seasons to prevent pesticide buildup.

Ready to Optimize Your Harvest?

Whether you’re a commercial apiary or a distributor supplying beekeepers, HONESTBEE’s durable uncapping tools and extraction systems help you save time, boost yields, and protect your most valuable asset—your bees’ hard work. Explore our solutions to make every harvest count.

Did You Know? A single bee colony can produce up to 100 pounds of honey per season—but only if their combs stay healthy enough to sustain production.

Visual Guide

Related Products

- Professional Honey Uncapping Fork Tool with Customizable Tine Options

- Stainless Steel Pivoting Honey Uncapping Fork with Plastic Handle

- Professional Stainless Steel Double-Sided Honey Uncapping Knife

- Professional Compact Multi-Function Uncapping Knife for Beekeeping

- All Stainless Steel Double Sided Pivoting Honey Uncapping Fork

Related Articles

- Precision Over Pace: The Economic Logic of the Uncapping Fork

- How Beginner Beekeepers Can Choose Their First Uncapping Tool: A Situational Guide

- Why Uncapping Rollers Outperform Traditional Hive Tools for Sustainable Beekeeping

- How Uncapping Forks Protect Honeycombs and Reduce Beekeeping Costs

- How to Uncap Honeycomb Safely: Professional Methods for Maximum Yield and Wax Preservation