Yes, temperature is a critical factor that directly affects the accuracy of a refractometer reading. Because a liquid's density changes with its temperature, the way light passes through it also changes, which can lead to incorrect measurements. To solve this, most modern refractometers are equipped with a feature called Automatic Temperature Compensation (ATC) to correct for these variations.

The core issue is that temperature alters a liquid's density, which in turn alters its refractive index. While Automatic Temperature Compensation (ATC) helps correct for the ambient temperature of the tool itself, the most accurate readings are only achieved when the sample and the refractometer are at the same temperature.

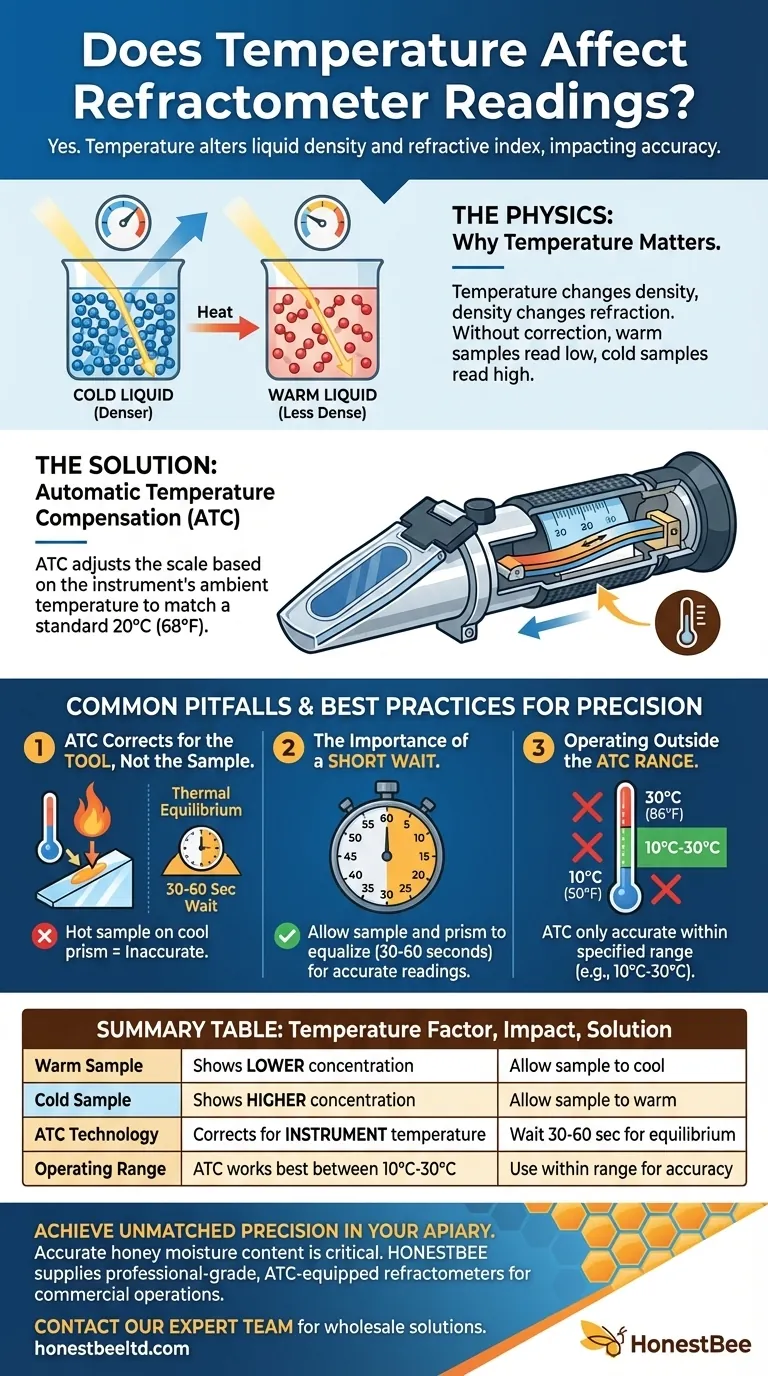

The Physics: Why Temperature Matters

A refractometer works by measuring how much a beam of light bends, or refracts, as it passes through a liquid sample. This measurement, the refractive index, is used to determine the concentration of dissolved solids—like sugar in honey or salt in water.

The Link Between Temperature and Density

When a liquid is heated, its molecules move faster and spread farther apart, causing the liquid to become less dense. Conversely, as a liquid cools, it becomes denser.

This physical change is the root of the measurement problem.

How Density Affects Refraction

The refractive index of a substance is directly related to its optical density. A denser liquid will bend light more than a less dense liquid.

Therefore, even if the concentration of sugar in your sample is constant, changing its temperature will change its density and thus change the reading on the refractometer.

The Result: Inaccurate Readings

Without correction, a warm sample will appear to have a lower concentration (e.g., lower Brix or moisture content) than it actually does. A cold sample will appear to have a higher concentration.

This can lead to significant errors in applications like brewing, beekeeping, or marine aquarium maintenance where precision is essential.

The Solution: Automatic Temperature Compensation (ATC)

To counter this effect, engineers developed refractometers with Automatic Temperature Compensation (ATC). This feature is now standard on most quality instruments.

What is ATC?

ATC is a built-in mechanism that automatically adjusts the refractometer's scale to offset readings based on the ambient temperature.

It ensures that the reading you see is what it would be if the measurement were taken at a standard calibration temperature, typically 20°C (68°F).

How ATC Works

Most ATC refractometers use a small, internal bimetallic strip. This strip is made of two different metals bonded together that expand and contract at different rates with temperature changes.

This physical movement is mechanically linked to the optics or scale, subtly shifting it to provide a corrected reading. It is calibrated to work accurately within a specific temperature range, often 10°C to 30°C (50°F to 86°F).

Common Pitfalls and Limitations

While ATC is a powerful feature, it is not a magic bullet. Understanding its limitations is key to achieving truly accurate measurements.

Pitfall #1: ATC Corrects for the Tool, Not the Sample

The most common misunderstanding is assuming ATC instantly corrects for a hot or cold sample. The bimetallic strip responds to the temperature of the instrument itself, not the liquid you just placed on it.

If you place a hot sample (e.g., boiling wort) onto a room-temperature refractometer prism, the reading will be inaccurate until the sample's heat has transferred to the prism and the instrument has reached a stable temperature. This is known as reaching thermal equilibrium.

Pitfall #2: The Importance of a Short Wait

To get an accurate reading, you must allow the sample and the prism to equalize in temperature. This typically takes between 30 and 60 seconds.

Applying a sample and taking an immediate reading, especially if there is a large temperature difference, will negate the benefits of ATC.

Pitfall #3: Operating Outside the ATC Range

An ATC refractometer is only accurate within its specified temperature range. If you try to take measurements in an environment that is significantly hotter or colder than this range, the bimetallic strip cannot compensate correctly, and your readings will be unreliable.

Making the Right Choice for Your Goal

To ensure your measurements are consistently accurate, apply the following principles based on your objective.

- If your primary focus is critical precision (brewing, lab work, quality control): Always allow your sample to cool to room temperature before placing it on the prism. Then, wait an additional 60 seconds for thermal equilibrium before taking the reading.

- If your primary focus is quick field measurements (honey, maple sap, coolants): Ensure your refractometer has been in the ambient environment for at least 15-20 minutes to acclimate. After applying the sample, still wait 30-60 seconds for the most reliable reading.

- If you are using a device without ATC: Your only path to accuracy is to bring both the refractometer and your sample to the specified calibration temperature (usually 20°C/68°F) or use a specific temperature correction chart for your application.

By understanding the relationship between temperature, time, and your instrument, you can ensure every reading is one you can trust.

Summary Table:

| Temperature Factor | Impact on Reading | Solution |

|---|---|---|

| Warm Sample | Shows lower concentration than actual | Allow sample to cool to room temperature |

| Cold Sample | Shows higher concentration than actual | Allow sample to warm to room temperature |

| ATC Technology | Corrects for instrument temperature | Wait 30-60 sec for sample/prism equilibrium |

| Operating Range | ATC works best between 10°C-30°C (50°F-86°F) | Use within specified range for accurate compensation |

Achieve Unmatched Precision in Your Apiary

For commercial beekeepers and distributors, accurate honey moisture content (Brix) readings are critical for quality control and profitability. Don't let temperature variations compromise your product's value.

HONESTBEE supplies professional-grade, ATC-equipped refractometers and other essential beekeeping supplies designed specifically for the demands of commercial operations. Our equipment delivers the reliability you need to ensure consistent, high-quality honey harvests.

Let us help you optimize your process. Contact our expert team today to discuss your specific needs and explore our wholesale-focused solutions.

Visual Guide

Related Products

- Digital Honey Refractometer for Precision Measurement of Optimal Honey Quality

- Precision Honey Refractometer Instrument for Quality Assessment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- Why is a high-precision refractometer essential in honey quality control? Ensure Stability and Prevent Fermentation

- What should be considered regarding the measurement range of a honey refractometer? Ensure Peak Honey Quality

- How do refractometers ensure technical precision when measuring honey moisture? Secure Quality and Prevent Fermentation

- How should a honey refractometer be calibrated for accuracy? Master Precision in Honey Moisture Analysis

- What are the main benefits of using a honey refractometer? Ensure Honey Quality & Market Compliance