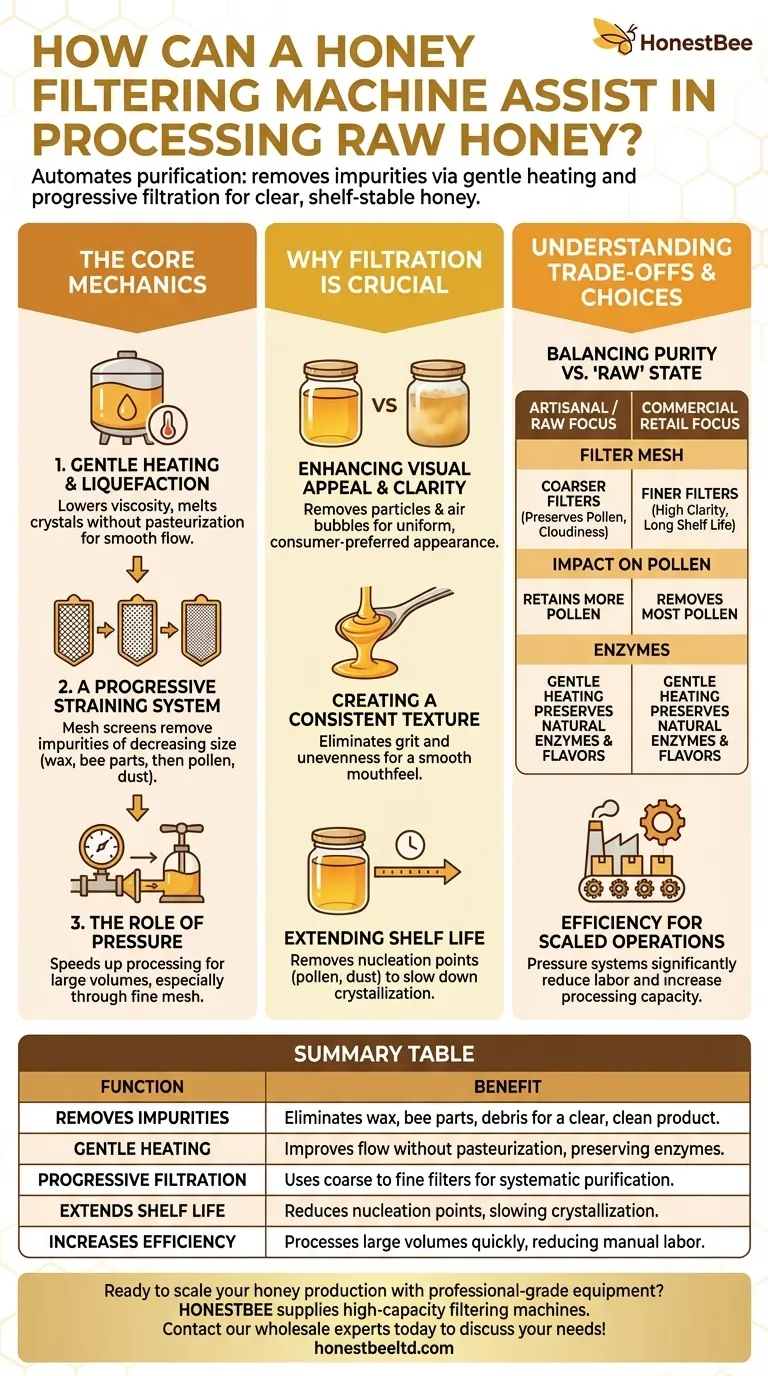

In short, a honey filtering machine automates the purification of raw honey. It systematically removes physical impurities like wax, bee parts, and other debris by gently heating the honey to improve its flow and then passing it through a series of progressively finer filters. This process is designed to create a clear, visually appealing, and shelf-stable product ready for bottling.

The central purpose of a honey filtering machine is to bridge the gap between raw, harvested honey and a market-ready product. It enhances honey's clarity, consistency, and shelf life, which are critical factors for commercial success, while increasing the efficiency of the entire production process.

The Core Mechanics of Honey Filtration

A honey filtering machine refines raw honey through a multi-stage process. Each step is engineered to purify the honey without degrading its natural quality.

Gentle Heating and Liquefaction

The process begins by gently heating the honey in a tank. This is not pasteurization. The goal is simply to lower the honey's viscosity and liquefy any sugar crystals that have formed, allowing it to flow smoothly through the filters.

A Progressive Straining System

Once warmed, the honey is passed through a series of mesh screens or filters. These filters are arranged from coarse to fine, systematically removing impurities of different sizes.

The initial filters catch larger debris like wax cappings and bee parts, while subsequent, finer filters trap smaller particles like pollen and dust.

The Role of Pressure

To improve speed and efficiency, especially in larger operations, some machines incorporate pressure systems. This pressure helps push the thick honey through the fine mesh filters more quickly than gravity alone would allow, significantly increasing the volume that can be processed.

Why Filtration is Crucial for Honey Quality

Filtering is not just about cleaning; it's a critical step in defining the final product's quality and marketability. It addresses the key attributes that consumers notice first.

Enhancing Visual Appeal and Clarity

The primary benefit is improved clarity. By removing suspended particles, sugar crystals, and air bubbles, the machine produces the crystal-clear honey that consumers often prefer. This uniform appearance enhances the product's appeal on a retail shelf.

Creating a Consistent Texture

Filtering ensures a smooth, consistent texture by removing all solid particles. This eliminates the gritty or uneven mouthfeel that can be caused by bits of wax or crystallized sugar, resulting in a higher-quality final product.

Extending Shelf Life

Impurities like pollen grains and dust can act as nucleation points, encouraging and accelerating the natural process of crystallization. By removing these particles, a filtering machine helps the honey remain in a liquid state for much longer, extending its shelf life.

Understanding the Trade-offs

While filtration is essential for commercial honey, it's important to understand the balance between purity and the "raw" state. The level of filtration directly impacts the final product's characteristics.

The Impact on Pollen

Very fine filters can remove most of the pollen from honey. For beekeepers marketing their product as "raw" or "unfiltered," this is a critical consideration. The choice of filter mesh size allows a producer to control how much pollen remains.

Preserving Natural Enzymes

The gentle heating used in filtration is specifically designed to avoid damaging the natural enzymes and delicate flavors present in raw honey. This distinguishes it from pasteurization, which uses much higher temperatures that can degrade these beneficial properties.

Efficiency for Scaled Operations

For any commercial beekeeping operation, a filtering machine offers a dramatic increase in efficiency. It can process a large volume of honey far more quickly and with less labor than manual straining methods, making it a cost-effective and necessary investment for growth.

Making the Right Choice for Your Goal

The right filtration strategy depends entirely on the product you want to create and the market you want to serve.

- If your primary focus is artisanal, raw honey: Use coarser filters to remove only large debris, intentionally preserving the pollen and natural cloudiness that signals an unprocessed product.

- If your primary focus is commercial retail: Employ a system with finer filters to achieve the high clarity and long shelf life required to compete in a supermarket environment.

- If your primary focus is operational efficiency: Investing in a machine with a pressure system is the most direct way to reduce labor costs and increase your processing capacity as your operation scales.

Ultimately, mastering the filtration process empowers you to precisely control the final product, ensuring it meets the exact standards your customers expect.

Summary Table:

| Function | Benefit |

|---|---|

| Removes Impurities | Eliminates wax, bee parts, and debris for a clear, clean product. |

| Gentle Heating | Improves flow without pasteurization, preserving natural enzymes. |

| Progressive Filtration | Uses coarse to fine filters for systematic purification. |

| Extends Shelf Life | Reduces nucleation points, slowing crystallization. |

| Increases Efficiency | Processes large volumes quickly, reducing manual labor. |

Ready to scale your honey production with professional-grade equipment?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the robust, high-capacity honey filtering machines and supplies needed to ensure product quality and maximize operational efficiency. Let us help you choose the perfect filtration system for your specific goals.

Contact our wholesale experts today to discuss your needs and get a quote!

Visual Guide

Related Products

- Electric Double Wall Honey Filtering Machine Purifier Equipment for Honey Processing Plant

- Professional Stainless Steel Honey Filtering Machine with Water Bath Heating for Beekeeping

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Manual Honey Filling Machine Bottling Machine for Honey

People Also Ask

- How does filtration equipment in bee product production lines contribute to GMO safety and regulatory compliance?

- What are the technical advantages of using a vacuum filtration system? Speed and Clarity for Separating Extracts

- What is the function of a honey filtering machine in relation to air bubbles? Stabilize Your Honey Quality

- In what way does a honey filtering machine reduce manual labor? Automate Your Harvest for Maximum Efficiency

- What is the function of high-precision Sieving Equipment in honey post-processing? Master Honey Purification

- What impact do industrial-grade filtration systems have on honey quality? Enhancing Purity and Shelf Life

- Why is it important to inspect and replace filters in honey filtering equipment? Protect Your Honey Quality & Equipment

- What are the benefits of using honey distribution centers? Scale Your Trade with Industrial Storage and Filtration