Automated honey extractors directly reduce physical strain by replacing the most labor-intensive step of the harvesting process: manually cranking a spinner to force honey out of the comb. Instead of repetitive, strenuous physical effort, an electric motor provides consistent, hands-off power, allowing the beekeeper to focus on other tasks while the machine does the heavy lifting.

The core benefit of automation in honey extraction is not just convenience; it is a strategic investment in efficiency and sustainability. By eliminating the primary source of physical strain, automated systems enable beekeepers to process more honey with less effort, making the practice more accessible and scalable.

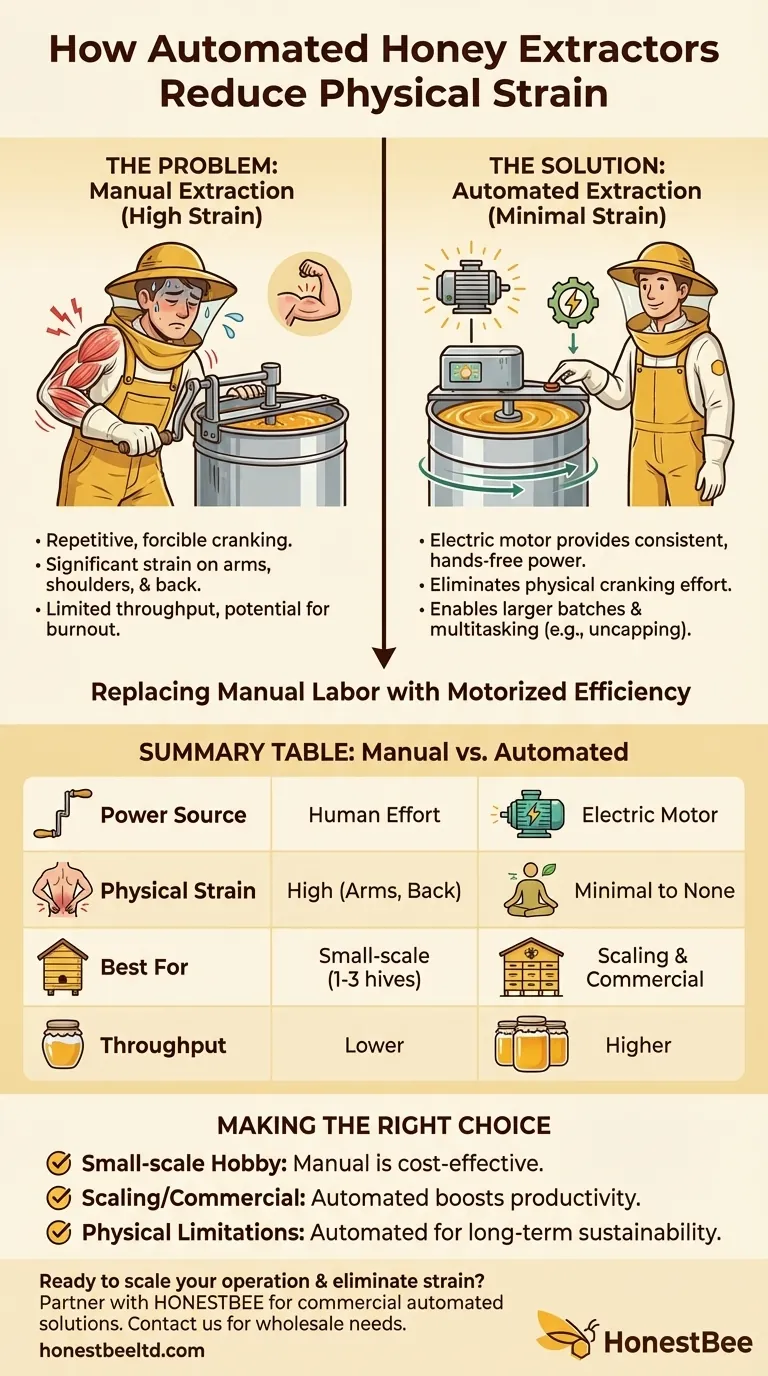

The Core Problem: The Physical Toll of Manual Extraction

Manual honey extraction is a rewarding but physically demanding process. The primary source of this strain comes from the repetitive and forceful action required to operate the equipment.

The Repetitive Strain of Cranking

A manual extractor requires the beekeeper to physically turn a crank, which spins a basket holding the honey frames. This action must be sustained with considerable force, especially with heavy frames full of honey, leading to strain on the arms, shoulders, and back.

The Challenge of Scale

For a beekeeper with only one or two hives, this effort may be manageable. However, as the number of hives grows, the sheer volume of frames to be extracted makes manual cranking a significant physical bottleneck and a source of potential burnout.

How Automation Solves the Physical Burden

Automated, or electric, extractors are engineered to eliminate this physical barrier entirely. They automate the spinning process, fundamentally changing the beekeeper's workflow.

Replacing Manual Cranking with Motorized Power

The defining feature of an automated extractor is its electric motor. This motor takes the place of the hand crank, spinning the frames at a consistent and controllable speed. The beekeeper simply needs to load the frames and press a button.

Enabling Larger, More Efficient Batches

Because the machine handles the spinning, beekeepers can often use larger extractors that hold more frames per cycle. This dramatically increases throughput and reduces the total time spent on the extraction process, minimizing overall physical handling.

Freeing Up the Beekeeper for Other Tasks

While the automated extractor is running, the beekeeper is free to perform other crucial tasks, such as uncapping the next batch of frames or filtering the extracted honey. This transforms the workflow from a series of strenuous, sequential steps into a more efficient, parallel operation.

Understanding the Trade-offs

While automation significantly reduces physical labor, it's important to weigh the benefits against the practical considerations.

The Initial Financial Investment

Automated extractors represent a higher upfront cost compared to their manual counterparts. This investment must be weighed against the expected time savings and reduction in physical labor.

Power Source Dependency

Electric extractors require a reliable source of electricity. For beekeepers operating in remote apiaries without grid access, this can pose a challenge, potentially requiring a generator or a robust battery system.

Making the Right Choice for Your Goal

Selecting the right extractor depends entirely on the scale of your operation and your personal goals.

- If your primary focus is a small-scale hobby with 1-3 hives: A manual extractor is often a cost-effective and sufficient tool for the job.

- If your primary focus is scaling your operation or commercial production: An automated extractor is a necessary investment to boost productivity and prevent physical burnout.

- If your primary focus is accessibility due to physical limitations: An automated extractor is the definitive choice to make beekeeping enjoyable and sustainable for the long term.

Ultimately, choosing the right tool empowers you to focus on the health of your bees and the quality of your honey, not the limitations of your equipment.

Summary Table:

| Feature | Manual Extractor | Automated Extractor |

|---|---|---|

| Power Source | Human effort (cranking) | Electric motor |

| Physical Strain | High (arms, shoulders, back) | Minimal to none |

| Best For | Small-scale hobbyists (1-3 hives) | Scaling operations & commercial production |

| Throughput | Lower, limited by user stamina | Higher, enables larger batch processing |

Ready to scale your operation and eliminate physical strain? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, reliable automated honey extractors through our wholesale-focused operations. Let us help you boost your productivity and make beekeeping more sustainable. Contact our team today to discuss your needs!

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

People Also Ask

- Why is cleaning a honey extractor important in beekeeping? Protect Your Honey Quality & Equipment

- What tool is used to extract honey? The Essential Guide to Honey Extractors & Harvesting

- What equipment is needed for extracting honey? A Complete Guide for Every Beekeeper

- What are the three basic types of honey extractors? Choose the Right Tool for Your Apiary

- What is the purpose of a honey extractor in beekeeping? Boost Hive Productivity & Honey Yields