In essence, automatic honey processing machines improve efficiency by automating the entire journey from raw honey to a market-ready product. They integrate tasks like extraction, filtration, heating, and bottling into a single, continuous workflow, which dramatically increases production speed, reduces the need for manual labor, and ensures a consistent, high-quality final product.

While the immediate benefit is speed, the true value of automated honey processing lies in achieving consistent quality at scale. It transforms honey production from a manual craft into a reliable, standardized, and more profitable manufacturing process.

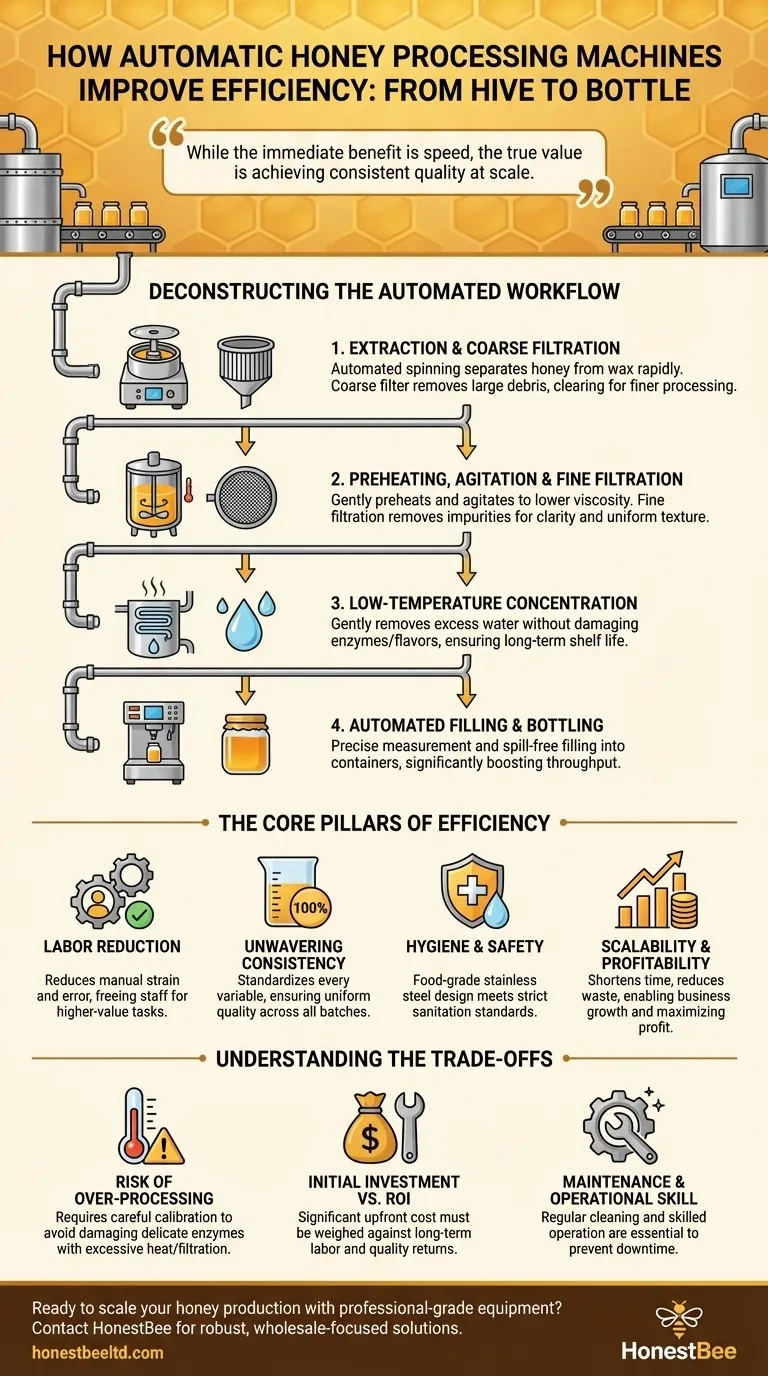

Deconstructing the Automated Workflow

To understand the efficiency gains, it's best to look at the process step-by-step. A typical automated line moves honey through several critical stages, each optimized for speed and quality control.

Step 1: Extraction and Coarse Filtration

The process begins with extracting honey from the comb. Automated extractors and spinners use centrifugal force to separate honey from the wax far more rapidly than manual crushing or pressing.

Immediately after extraction, the honey passes through a coarse filter. This automated step removes large debris like wax particles, bee parts, and wood splinters, clearing the way for finer processing.

Step 2: Preheating, Agitation, and Fine Filtration

Raw honey is often too thick to filter effectively. The system gently preheats and agitates the honey in holding tanks to lower its viscosity, making it easier to pump and process.

Next, the honey is forced through a fine filtration system. This removes smaller impurities like pollen, air bubbles, and fine wax particles, resulting in the clear, pure honey consumers expect. This automated stage ensures a uniform texture and appearance across all batches.

Step 3: Low-Temperature Concentration

Some automated systems include a low-temperature concentration (or dehumidifying) stage. This gently removes excess water content from the honey without damaging its natural enzymes and flavors through overheating.

Proper moisture content is critical for preventing fermentation and ensuring long-term shelf life, a quality control measure that is difficult to standardize manually.

Step 4: Automated Filling and Bottling

The final stage is filling. An automated filler measures the precise amount of honey for each container and fills it without spills or inconsistencies. This step alone provides a massive boost in throughput compared to hand-bottling.

The Core Pillars of Efficiency

The workflow improvements translate into four fundamental business advantages: consistency, safety, scalability, and labor reduction.

Reducing Manual Labor and Human Error

Every step—from lifting heavy honey supers to meticulously filling jars—is a source of physical strain and potential error. Automation handles these repetitive, demanding tasks, freeing up staff to focus on quality oversight and other higher-value activities.

Ensuring Unwavering Product Consistency

Manual processing can lead to variations in color, texture, and purity between batches. Automation standardizes every variable, from heating temperature to filtration level, ensuring that the first bottle looks and tastes exactly like the last. This consistency is crucial for building brand reputation and client trust.

Meeting Hygiene and Safety Standards

Automated systems are typically built from food-grade, corrosion-free stainless steel and are designed for easy cleaning and sanitation. This helps producers meet stringent food safety regulations, safeguarding consumer health and protecting the business from liability.

Enabling Scalability and Profitability

By shortening processing time and reducing waste, automation allows a business to produce significantly more honey without a proportional increase in costs. This efficiency directly enables business growth and maximizes the potential profit from each harvest.

Understanding the Trade-offs

While powerful, automation is not a universal solution. It's essential to understand the associated considerations to make an informed decision.

The Risk of Over-Processing

It is possible to damage honey with automation. Aggressive filtering can strip out beneficial pollen, and excessive heat can destroy delicate enzymes and flavors. High-quality equipment is designed to avoid this, but it requires careful calibration to balance purity with preserving the honey's natural character.

Initial Investment vs. Long-Term ROI

A fully automated processing line represents a significant capital investment. The upfront cost must be weighed against the long-term return from reduced labor costs, increased output, and higher product quality. This is a business decision, not just a technical one.

Maintenance and Operational Skill

Automatic systems are not "set and forget." They require regular cleaning and maintenance to prevent downtime and ensure sanitation. Operating the equipment also requires a degree of technical skill to manage settings and troubleshoot issues.

Making the Right Choice for Your Operation

The decision to automate depends entirely on your production goals and scale.

- If your primary focus is artisanal, small-batch production: A semi-automated extractor and a simple filtration setup may be all you need to reduce labor while maintaining a hands-on approach.

- If your primary focus is scaling a growing business: An integrated system that automates extraction, filtration, and bottling is the logical next step for achieving consistency and meeting rising demand.

- If your primary focus is large-scale commercial distribution: The most advanced systems, including features like low-temperature concentration and precise quality control, are essential for maximizing output and meeting rigorous market standards.

Ultimately, adopting the right level of automation empowers you to produce a better, more consistent product with far greater efficiency.

Summary Table:

| Efficiency Benefit | Key Impact |

|---|---|

| Speed & Throughput | Continuous workflow dramatically increases production volume. |

| Labor Reduction | Automates repetitive tasks, freeing staff for higher-value work. |

| Product Consistency | Ensures uniform quality, color, and texture across all batches. |

| Hygiene & Safety | Food-grade stainless steel design meets strict sanitation standards. |

| Scalability | Enables business growth by maximizing output and profitability. |

Ready to scale your honey production with professional-grade equipment?

At HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with robust, wholesale-focused honey processing solutions. Our automated systems are designed to help you achieve higher throughput, unwavering quality, and greater profitability.

Contact our experts today to discuss the right automation setup for your operation!

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Manual Honey Filling Machine Bottling Machine for Honey

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Electric Double Wall Honey Filtering Machine Purifier Equipment for Honey Processing Plant

People Also Ask

- What role do automated honey-filling machines play in trade standards? Ensure Global Export Compliance & Consistency

- What role do honey filling machines play in meeting quality standards? Ensure Global Export Compliance

- What are the primary benefits of automated honey-filling machines? Scale Your Commercial Apiary Efficiency

- What role does honey-filling and processing machinery play in pollination? Maximize Apiary ROI & Economic Stability

- How do industrial honey filling machines ensure compliance? Master Quality Control for Global Export