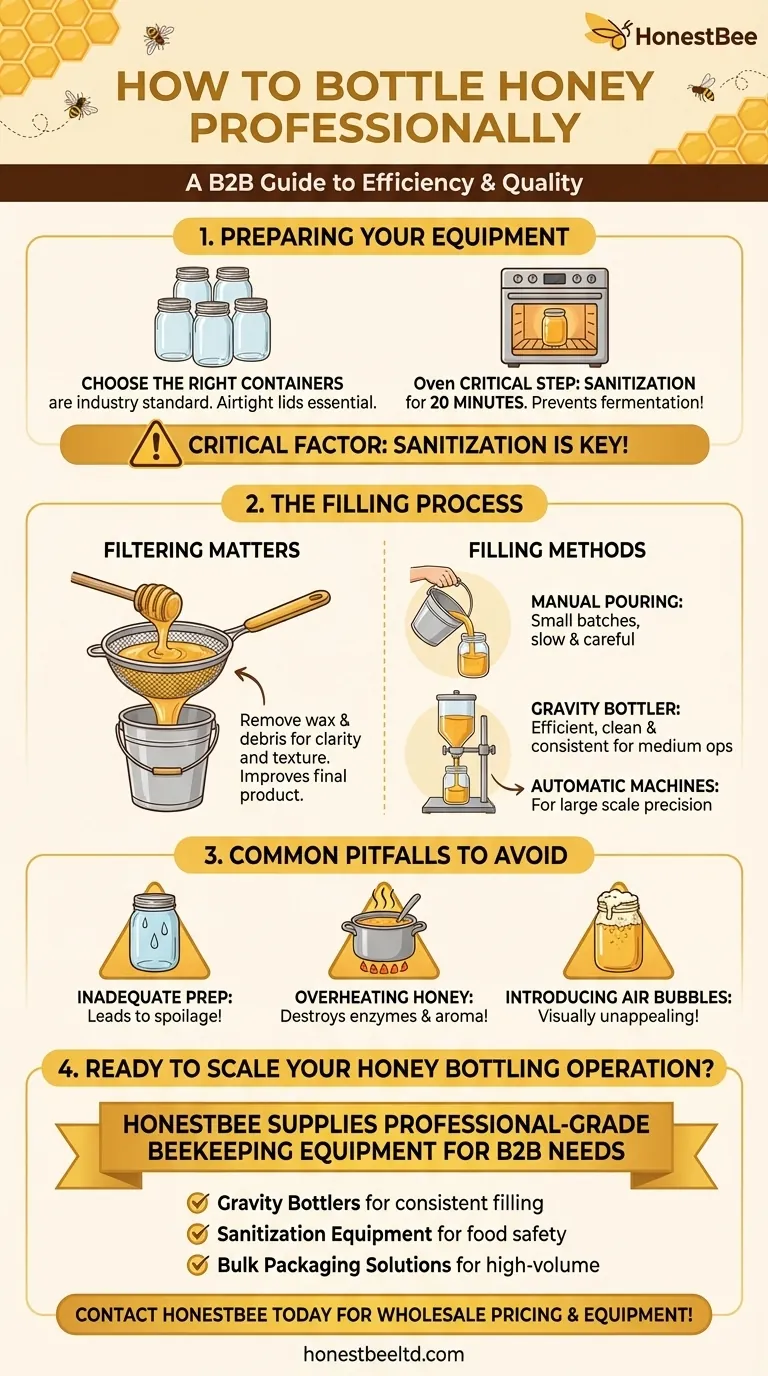

To bottle honey, you must use clean, sanitized jars, filter the raw honey to remove wax and debris, and then carefully pour the honey into the containers, minimizing air bubbles. The most common and effective containers are glass Mason or canning jars, which should be sanitized in an oven to ensure the honey remains pure and does not ferment.

The single most critical factor in bottling honey is sanitization. Proper cleaning and sterilization of your jars and equipment are essential to prevent contamination and preserve the honey's natural quality, just as the bees intended.

Preparing Your Equipment

Proper preparation is the foundation of a successful bottling process. Skipping these steps can compromise the quality and shelf-life of your final product.

Choose the Right Containers

Glass jars, such as Mason or canning jars, are the industry standard for honey. They are non-reactive, provide an excellent seal, and allow the color and clarity of the honey to be displayed.

Ensure your chosen jars come with new lids that will create an airtight seal, protecting the honey from moisture and contaminants.

The Critical Step: Sanitization

Sanitization eliminates any yeast or bacteria that could cause your honey to ferment over time. This is a non-negotiable step for long-term storage.

A simple and effective method is to wash your jars thoroughly and then place them in an oven. Heat the jars for 20 minutes at 225°F (107°C) to ensure they are completely sterile before you begin filling.

The Filling Process

Once your jars are sanitized and your honey is extracted, you can move on to the bottling stage. The method you choose will depend on the scale of your operation.

Why Filtering Matters

Before bottling, it's wise to filter the honey to remove any remaining bits of wax, honeycomb, or other hive debris. This is typically done by passing the honey through a fine mesh strainer or cheesecloth.

This step improves the honey's clarity and texture, resulting in a more professional and appealing final product.

Manual Pouring for Small Batches

For hobbyists or small-scale beekeepers, carefully pouring the honey directly from a container with a spout (often called a honey bucket or bottling bucket) is perfectly sufficient. Pour slowly and down the side of the jar to minimize the introduction of air bubbles.

Using a Bottler for Efficiency

For small to medium operations, a gravity bottler is a significant step up. This device uses a simple valve to control the flow of honey, making the filling process faster, cleaner, and more consistent.

For large commercial beekeepers, automatic filling machines handle the process with high speed and precision, filling multiple bottles at once.

Common Pitfalls to Avoid

Attention to detail prevents common mistakes that can affect the quality of your bottled honey. Being aware of these potential issues is key to a successful outcome.

Inadequate Jar Preparation

Failing to properly wash and sanitize jars is the most common error. Any residual moisture or contaminants can introduce wild yeasts, leading to fermentation and spoiled honey.

Overheating the Honey

If your honey is too thick to pour easily, you can warm it gently in a water bath. However, never overheat it. Excessive heat can destroy the delicate enzymes and aromas that make raw honey special.

Introducing Air Bubbles

Pouring honey too quickly or from too great a height can trap air bubbles. While not harmful, these bubbles can create a foamy layer at the top of the jar, which can be visually unappealing.

Making the Right Choice for Your Goal

Your bottling strategy should align with your ultimate goal for the honey.

- If your primary focus is personal use or small gifts: Simple manual pouring into well-sanitized Mason jars is the most practical and cost-effective method.

- If your primary focus is scaling up for farmers' markets: Investing in a gravity bottler will significantly improve your efficiency and the professional appearance of your product.

- If your primary focus is preserving raw honey qualities: Minimize any heating and handle the honey as gently as possible during filtering and pouring to protect its natural enzymes and flavor.

Following these steps ensures your hard-earned honey is bottled safely, preserving its quality for you and others to enjoy.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Prepare Jars | Sanitize glass jars (e.g., Mason jars) at 225°F for 20 min. | Prevents fermentation and contamination. |

| 2. Filter Honey | Strain raw honey through a fine mesh or cheesecloth. | Removes wax and debris for a clear product. |

| 3. Fill Jars | Pour slowly or use a gravity bottler to minimize air bubbles. | Ensures a professional, appealing finish. |

| 4. Avoid Pitfalls | Don't overheat honey; ensure jars are completely dry. | Preserves natural enzymes and flavor. |

Ready to Scale Your Honey Bottling Operation?

For commercial apiaries and beekeeping equipment distributors, efficiency and quality are paramount. HONESTBEE supplies professional-grade beekeeping supplies and equipment through wholesale-focused operations, helping you streamline the bottling process from extraction to shelf.

We provide:

- Gravity Bottlers for consistent, clean filling.

- Sanitization Equipment to meet food safety standards.

- Bulk Packaging Solutions tailored for high-volume needs.

Let us help you protect the integrity of your honey while boosting productivity. Contact HONESTBEE today to discuss wholesale pricing and equipment tailored for your business!

Visual Guide

Related Products

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- 10L Stainless Steel Electric Honey Press Machine

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Honey Gate Valve with Ergonomic Ball Handle Plastic Bee Honey Tap for Beekeeping Bottling and Honey Extractor Equipment

People Also Ask

- How do industrial honey-filling machines enhance the commercial distribution of bee products? Maximize Your Market Reach

- How can a packing process be customized for a diverse range of products? Master Efficient Packing for Honey & Pastes

- How does a semi-automatic filling machine operate? Boost Your Production Consistency

- Why must advanced automated honey filling and packaging equipment be used? Secure Medicinal-Grade Purity and Bioactivity

- What technical advantages does high-precision automated filling equipment offer? Boost Your Honey Production Quality

- What technical advantages do industrial-grade honey filling machines provide? Boost Your Commercial Honey Quality

- What problems are addressed by using specialized honey filtration and filling equipment? Scaling Melipona Honey Quality

- What are the key characteristics of a honey stick filling machine? High-Precision Packaging Solutions