Effectively removing moisture from honey is a critical step to ensure its long-term stability and prevent spoilage. The process universally relies on creating conditions where water can evaporate from the honey into the surrounding air. This is achieved by either heating a room and using a dehumidifier, or by using specialized equipment that circulates warm, dry air over the honey to draw out excess water.

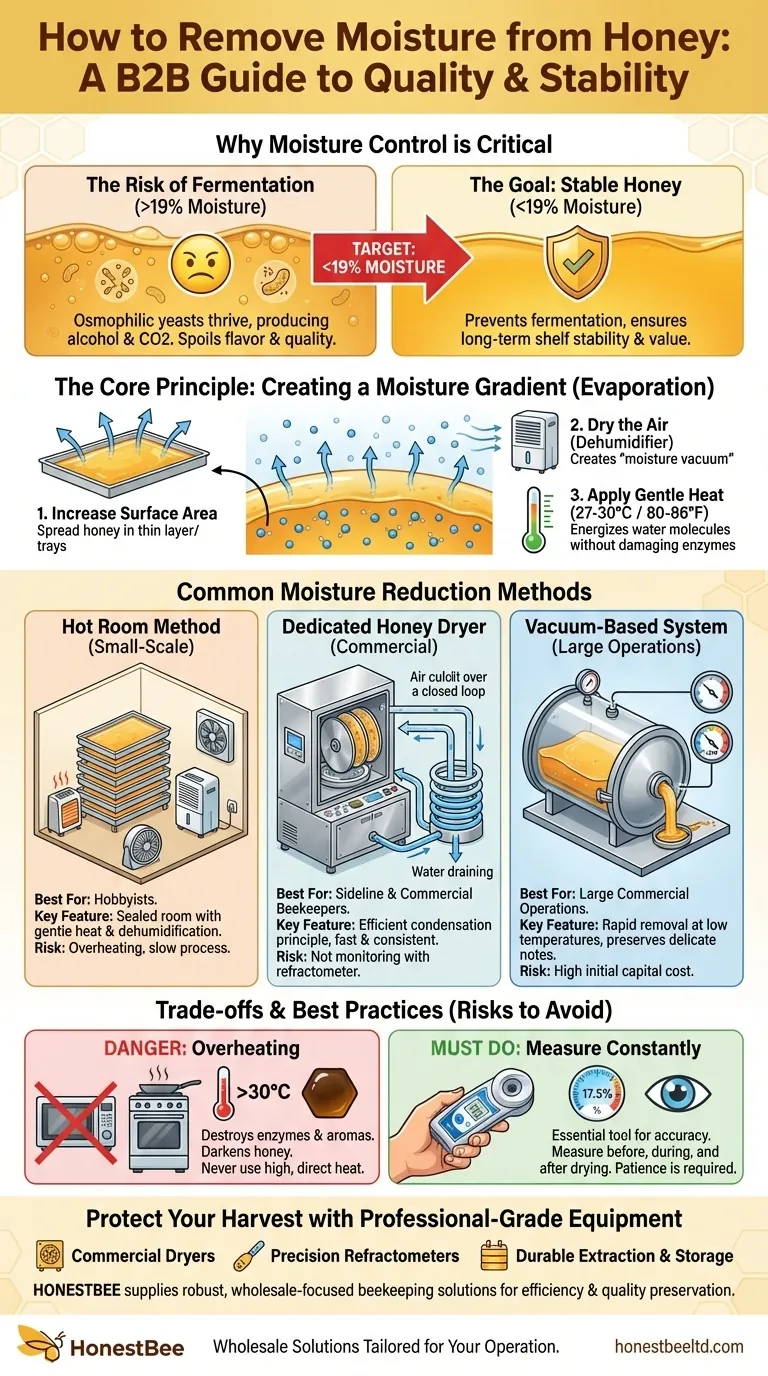

The core challenge is that honey with a moisture content above 19% is susceptible to fermentation by natural yeasts, which spoils its flavor and quality. The solution is to create a moisture gradient—making the air drier than the honey—to encourage evaporation without using excessive heat that would damage the honey's delicate enzymes and aroma.

Why Moisture Content is Critical in Honey

Controlling moisture is not just about preference; it's fundamental to producing high-quality, shelf-stable honey.

The Risk of Fermentation

Honey with a high water content provides the perfect environment for osmophilic yeasts to thrive. These naturally occurring yeasts consume the sugars in honey, producing alcohol and carbon dioxide.

This process, known as fermentation, results in off-flavors, a sour taste, and a bubbly appearance, rendering the honey spoiled and unsuitable for sale or consumption. The widely accepted safety threshold is a moisture content below 19%.

Common Causes of High Moisture

High moisture is often a result of environmental factors or harvesting practices. Key causes include harvesting during wet or humid seasons, operating in a naturally humid climate, or extracting honey from combs that are not fully capped by the bees. Accidentally introducing water during the extraction process can also elevate moisture levels.

The Core Principle: Creating a Moisture Gradient

All effective drying methods are based on the simple physics of evaporation. To remove water from honey, you must encourage it to leave the liquid and enter the air as vapor.

The Goal is Evaporation

The fundamental goal is to make it easier for water molecules to escape the honey than to stay in it. This requires manipulating the honey and the air around it.

The Role of Surface Area

Honey is viscous, which traps water within it. Spreading the honey into a thin layer dramatically increases its surface area, exposing more water molecules to the air and significantly speeding up the evaporation rate. This is why methods using rotating discs or shallow trays are effective.

The Role of Air and Humidity

For water to evaporate, the air touching the honey must be able to absorb it. If the air is already saturated with moisture (high humidity), evaporation will be slow or stop completely.

A dehumidifier is essential because it pulls water vapor out of the air, creating a "moisture vacuum" that actively draws water from the honey.

The Role of Gentle Heat

Applying gentle warmth (ideally 27–30 °C or 80-86 °F) gives water molecules the extra energy they need to evaporate more quickly. However, this is a delicate balance, as excessive heat will damage the honey.

Common Methods for Moisture Reduction

Methods range from simple DIY setups for hobbyists to sophisticated commercial equipment.

The "Hot Room" Method

This is a common approach for beekeepers of all sizes. An entire room or insulated chamber is heated gently while one or more dehumidifiers run continuously.

Honey can be left in stacked barrels or supers, or poured into shallow pans to increase surface area. A fan to circulate air ensures that dry air consistently reaches all honey surfaces. This is a slow but safe and effective method.

Dedicated Honey Dryers

These specialized machines work on a highly efficient condensation principle. They create a closed loop where warm, dry air is blown over thin layers of honey (often flowing over a series of plates or discs).

The now-moist air is then drawn over a cold evaporator coil, which causes the water to condense and drain away. The newly dry air is reheated and recirculated back over the honey. This is faster and more controlled than the hot room method.

Vacuum-Based Systems

Used in larger commercial operations, vacuum systems lower the boiling point of water. This allows for rapid moisture removal at very low temperatures, which is ideal for preserving the most delicate floral notes and enzymes in high-value honey.

Understanding the Trade-offs and Risks

While reducing moisture is necessary, doing it improperly can cause more harm than good.

The Danger of Overheating

Never use high, direct heat like microwaves or stovetops. Excessive temperatures will destroy the beneficial enzymes (like diastase and invertase) and complex aromas that make honey valuable. Overheating will also darken the honey and can even caramelize its sugars.

The Importance of Measurement

You cannot manage what you do not measure. A honey refractometer is an essential tool for accurately reading the moisture content. You must measure the honey's moisture level before, during, and after the drying process to know when you have reached your target.

Patience is a Virtue

Safe, low-temperature moisture removal takes time, often several days. Rushing the process with high heat is the most common mistake and will compromise the quality of your final product.

Making the Right Choice for Your Goal

Your equipment choice should match the scale of your operation and your quality goals.

- If you are a small-scale hobbyist: The "hot room" method is your best choice, using a small, sealed room with a consumer-grade dehumidifier, a small heater, and a fan.

- If you are a sideline or commercial beekeeper: A dedicated honey dryer is a worthwhile investment for its speed, efficiency, and consistent results.

- Regardless of your scale: Always use a refractometer to guide your process and confirm you have safely reached a moisture level below 19%.

By carefully controlling temperature and humidity, you can reliably protect the quality and value of your harvest.

Summary Table:

| Method | Best For | Key Feature | Risk to Avoid |

|---|---|---|---|

| Hot Room with Dehumidifier | Small-scale hobbyists | Uses a sealed room with gentle heat & dehumidifier | Overheating (>86°F / 30°C) damages enzymes |

| Dedicated Honey Dryer | Sideline & commercial beekeepers | Recirculates warm, dry air over thin honey layers | Not using a refractometer to monitor progress |

| Vacuum System | Large commercial operations | Rapid moisture removal at low temperatures | High initial equipment cost |

Protect Your Honey Harvest with Professional-Grade Equipment

Are you a commercial apiary or beekeeping equipment distributor struggling with high moisture levels that risk fermentation and spoilage? HONESTBEE supplies robust, wholesale-focused beekeeping supplies and equipment designed for efficiency and honey quality preservation.

We provide:

- Commercial-grade honey dryers for fast, consistent moisture reduction.

- Precision refractometers to accurately monitor moisture content.

- Durable extraction and storage equipment that integrates seamlessly into your workflow.

Invest in equipment that safeguards your product's value and meets market standards. Contact our experts today to discuss wholesale solutions tailored for your operation.

Visual Guide

Related Products

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- Professional Thermostatic Conical Honey Melter

People Also Ask

- Does honey draw out moisture? The Science of Honey's Hygroscopic Nature

- Why is it necessary to maintain strict control over moisture content in honey? Ensure Stability and Prevent Spoilage

- How do high-efficiency honey dehydration and filtration systems enhance honey quality and unit yield? Optimize Your Honey

- What are the key features of the honey dryer? Essential Guide to Advanced Moisture Reduction Technology

- What is the role of industrial spray drying equipment in the deep processing of stingless bee honey?

- What role does specialized storage and climate control equipment play in honey distribution? Maintain Bulk Honey Quality

- Why is industrial dehydration equipment necessary for honey preservation? Stop Fermentation and Ensure Stability

- What is the function of laboratory-grade moisture control equipment? Stabilize and Secure Stingless Bee Honey Quality