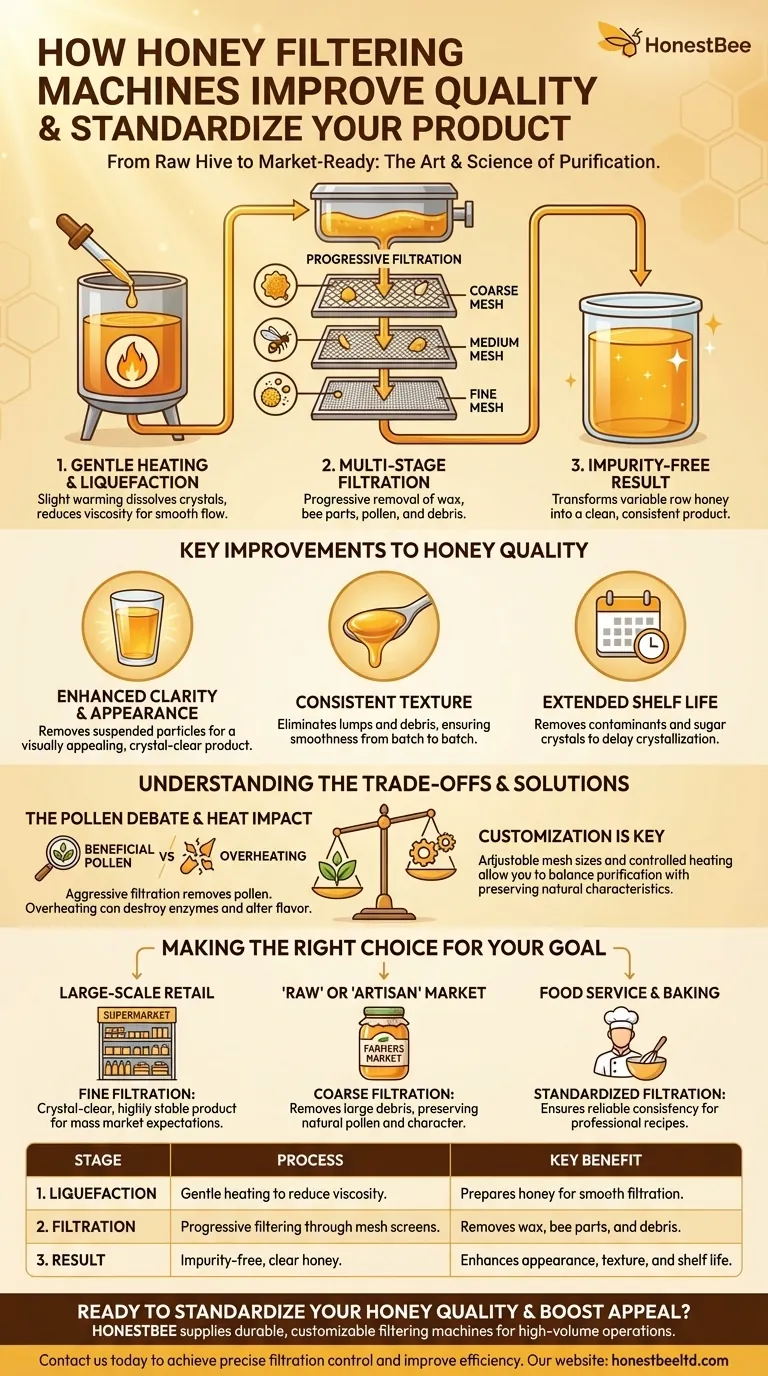

At its core, a honey filtering machine improves the quality of honey by systematically removing physical impurities like wax, bee parts, and debris. This mechanical purification process transforms raw, variable honey from the hive into a clean, visually appealing, and consistent product ready for the market.

A honey filtering machine is not just about cleaning honey; it’s about standardization. It refines the honey's clarity, texture, and shelf life to meet specific quality standards and consumer expectations.

The Mechanics of Purification

A honey filtering machine operates on a multi-stage principle designed to gently but effectively remove unwanted particulates without damaging the honey itself.

Stage 1: Gentle Heating and Liquefaction

The process begins when harvested honey is poured into a tank. Here, it is often gently heated.

This slight warming is critical as it dissolves sugar crystals and reduces the honey's viscosity, allowing it to flow more smoothly through the filters.

Stage 2: Progressive Filtration

The warmed honey then passes through a series of filters or mesh screens.

These screens are arranged in a progressive sequence, starting with a coarser mesh to catch large debris and moving to progressively finer ones to trap smaller particles.

Stage 3: What Is Being Removed

This mechanical separation targets several specific impurities.

The primary elements removed are wax particles, bee parts, pollen, and other hive debris. It also removes existing sugar crystals, which act as seeds for further crystallization.

Key Improvements to Honey Quality

By removing these impurities, the machine delivers several tangible benefits that define a high-quality honey product.

Enhanced Clarity and Appearance

The most immediate improvement is visual. Removing suspended particles and air bubbles results in a crystal-clear product that is highly appealing to consumers.

Consistent Texture

Filtering eliminates lumps of wax and other debris, ensuring a uniformly smooth and pleasant texture from batch to batch. This consistency is crucial for building a reliable brand.

Extended Shelf Life

By removing contaminants and the tiny sugar crystals that can trigger widespread crystallization, a filtering machine helps keep honey in its liquid state for longer, extending its shelf life.

Understanding the Trade-offs

While filtration offers clear benefits, it's essential to understand the nuances and potential downsides to make an informed decision.

The Pollen Debate

Aggressive, ultra-fine filtration can remove beneficial pollen grains. Many consumers specifically seek out the pollen in "raw" or "unfiltered" honey for its perceived health benefits and unique flavor profile.

The Impact of Heat

The "gentle heating" stage must be carefully controlled. Overheating honey can destroy its natural enzymes and subtly alter its delicate flavor, which purists would consider a reduction in quality.

Customization is the Solution

Modern filtering machines address these concerns with customizable options. Beekeepers can choose different mesh sizes for their filters, allowing them to control the outcome.

A coarse filter can remove large debris while leaving pollen intact, whereas a fine filter will produce a perfectly clear liquid.

Making the Right Choice for Your Goal

The "best" level of filtration depends entirely on your product goals and target market.

- If your primary focus is large-scale commercial retail: Fine filtration is essential to produce the crystal-clear, highly stable product that most consumers expect on a supermarket shelf.

- If your primary focus is the 'raw' or 'artisan' market: Use a coarse filtration method to remove only large debris like wax, preserving the natural pollen and character of the honey.

- If your primary focus is consistency for food service or baking: A standardized filtration process ensures every batch has the same texture and purity, guaranteeing reliable results in recipes.

Ultimately, mastering the filtration process allows you to precisely control your honey's final characteristics to meet the exact demands of your market.

Summary Table:

| Stage | Process | Key Benefit |

|---|---|---|

| 1. Liquefaction | Gentle heating to reduce viscosity. | Prepares honey for smooth filtration. |

| 2. Filtration | Progressive filtering through mesh screens. | Removes wax, bee parts, and debris. |

| 3. Result | Impurity-free, clear honey. | Enhances appearance, texture, and shelf life. |

Ready to Standardize Your Honey Quality and Boost Your Market Appeal?

For commercial apiaries and beekeeping equipment distributors, the right filtration equipment is key to producing a consistent, high-quality product. HONESTBEE supplies durable, customizable honey filtering machines designed for high-volume, wholesale operations.

Contact us today to discuss how our solutions can help you achieve precise filtration control, improve efficiency, and meet the specific demands of your target market.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- Why is filtering important in honey processing, and what equipment is used? A Guide to Quality & Efficiency

- How does using a honey filtering machine help in minimizing contamination? Ensure Pure, High-Quality Honey Standards

- What is the primary purpose of a honey filtering machine? Purify & Market Your Honey Efficiently

- How does the use of food-grade fine filtration equipment affect the color and clarity of processed honey? Master Purity

- How does honey filtration and homogenization equipment affect the commercial value of Robinia pseudoacacia honey?

- How does honey filtration equipment impact honey quality? Enhance Clarity and Market Value for Premium Sales

- How should honey filtering equipment be maintained? Essential Care for Longevity and Purity

- In what way does a honey filtering machine reduce manual labor? Automate Your Harvest for Maximum Efficiency