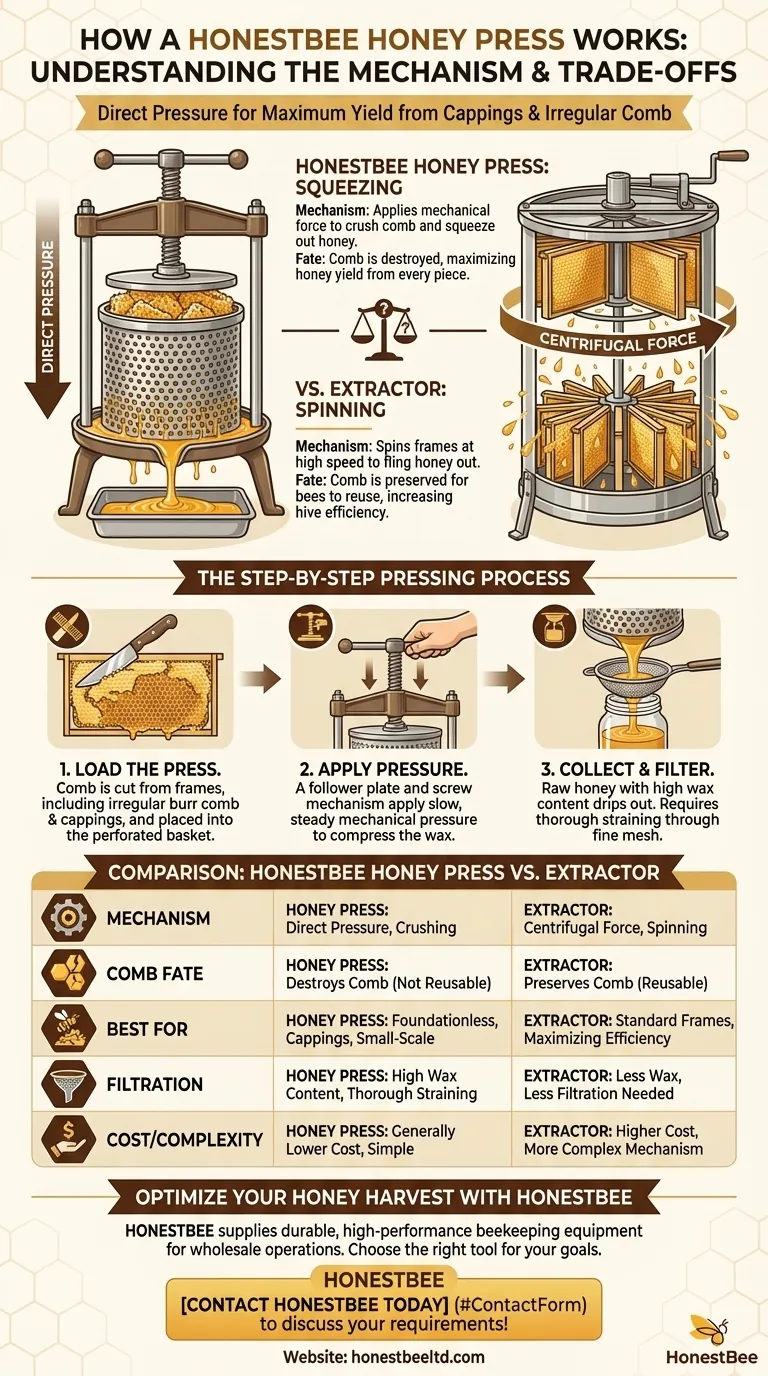

At its core, a honey press works by applying direct mechanical pressure to crush honeycomb and squeeze out the honey. It is a simple, effective tool that operates on the principle of compression, forcing honey out of the wax structure. This is fundamentally different from a centrifugal extractor, which spins frames to release honey without destroying the comb.

Choosing a honey extraction method is not just about getting honey; it's about deciding the fate of your beeswax comb. A press maximizes your yield by destroying the comb, while an extractor is designed to preserve it for the bees to reuse.

Press vs. Extractor: A Critical Distinction

Many sources incorrectly use the terms "press" and "extractor" interchangeably. They are two distinct tools with different mechanisms and outcomes. Understanding this difference is the first step to making an informed decision for your apiary.

How a Honey Press Works: Squeezing

A honey press uses a screw or lever mechanism to drive a pressure plate downwards onto a mass of honeycomb.

The comb is held within a perforated basket or cylinder. As it's crushed under immense force, the liquid honey is squeezed out through the perforations.

The raw honey then drips into a collection tray below, often passing through a primary sieve to catch the largest pieces of crushed wax.

How a Honey Extractor Works: Spinning

An extractor, by contrast, operates on centrifugal force. Intact honey frames are placed inside a large drum and spun at high speed.

This spinning motion flings the honey out of the individual cells, leaving the underlying wax comb structure intact.

This method's primary purpose is to preserve the delicate and energy-intensive comb so it can be returned to the hive for the bees to refill.

The Step-by-Step Pressing Process

Operating a honey press is a straightforward mechanical procedure focused on methodical compression.

Step 1: Load the Press

Comb is first cut away from its frame and placed into the press's perforated basket. This can include full combs, irregular pieces of "burr comb," or the wax cappings that are sliced off frames prior to centrifugal extraction.

Step 2: Apply Pressure

A solid follower plate is placed on top of the comb. The operator then turns a T-shaped handle, which is connected to a large screw.

This screw drives the plate down, slowly and steadily compressing the wax and honey mixture. Applying slow, even pressure is key to preventing blowouts and ensuring maximum yield.

Step 3: Collect and Filter

As pressure mounts, honey flows from the basket's holes into a collection pan.

This raw, pressed honey will contain a higher proportion of wax particles than extracted honey. It requires thorough straining, typically through progressively finer layers of mesh or cheesecloth, before it is ready for bottling.

Understanding the Trade-offs

A honey press is a powerful tool, but its use comes with clear advantages and disadvantages that you must weigh.

Advantage: Maximizing Yield from Scraps

A press excels at processing comb that isn't suitable for an extractor, such as foundationless comb, broken pieces, and especially wax cappings. It ensures that every last drop of honey is recovered from material that might otherwise be difficult to process.

Advantage: Simplicity and Lower Cost

Honey presses are mechanically simple, highly durable, and often more affordable and compact than centrifugal extractors. This makes them an accessible entry point for hobbyists with only a few hives.

The Critical Disadvantage: Comb Destruction

The primary trade-off is that pressing completely destroys the drawn comb. Bees expend enormous energy to produce wax, consuming many pounds of honey to create just one pound of comb. Reusing comb saves them this work, allowing them to focus on nectar collection and honey production.

The Filtration Requirement

Because pressing crushes the entire wax structure, the resulting honey contains more suspended wax solids. This necessitates a more intensive and time-consuming filtration process to achieve a clear, clean final product.

Making the Right Choice for Your Apiary

Your specific beekeeping goals will determine which tool is right for you.

- If your primary focus is preserving comb for reuse and maximizing hive efficiency: An extractor is the correct tool, as it saves the bees the immense work of rebuilding their wax structure.

- If your primary focus is processing foundationless comb, wax cappings, or you are a small-scale beekeeper prioritizing simplicity and cost: A honey press is a highly effective choice that ensures no honey is wasted.

Ultimately, understanding this fundamental difference in mechanism empowers you to select the precise tool that aligns with your beekeeping philosophy and operational goals.

Summary Table:

| Feature | Honey Press | Honey Extractor |

|---|---|---|

| Mechanism | Applies direct pressure to crush comb | Spins frames using centrifugal force |

| Comb Fate | Destroys the wax comb | Preserves the wax comb for reuse |

| Best For | Foundationless comb, cappings, small-scale beekeeping | Standard framed comb, maximizing hive efficiency |

| Filtration | Requires thorough straining due to high wax content | Less filtration needed |

| Cost/Complexity | Generally lower cost and mechanically simple | Higher cost and more complex mechanism |

Optimize Your Honey Harvest with the Right Equipment

Whether you're a commercial apiary focused on efficiency or a distributor supplying beekeepers, choosing the correct extraction method is crucial for maximizing yield and productivity. HONESTBEE supplies durable, high-performance beekeeping supplies and equipment, including honey presses and extractors, tailored for wholesale operations.

Let our experts help you select the perfect tool for your specific needs.

Contact HONESTBEE today to discuss your equipment requirements and boost your honey production!

Visual Guide

Related Products

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- What is the proper method for cleaning a honey press? Maintain Hygiene and Equipment Longevity

- How should a honey press be cleaned after it has been used? Essential Maintenance Tips for Your Harvest Tools

- Which types of beehive frames are suitable for use with a honey press? Top Bar and Foundationless Frames Explained

- What is the recommended temperature for using a honey press? Optimize Your Extraction Efficiency

- What role does professional honey pressing equipment play in the production of honey? Enhance Your Raw Honey Quality