In short, an insulating foam board serves two critical functions for a wintering beehive. It dramatically reduces heat loss and, more importantly, helps control the deadly buildup of internal moisture. This allows the colony to expend less energy and food staying warm, significantly increasing its chances of survival.

The primary goal of winter insulation is not just to keep bees warm, but to create a stable, dry environment. By preventing condensation and reducing the colony's workload, you are saving their energy stores for a strong start in the spring.

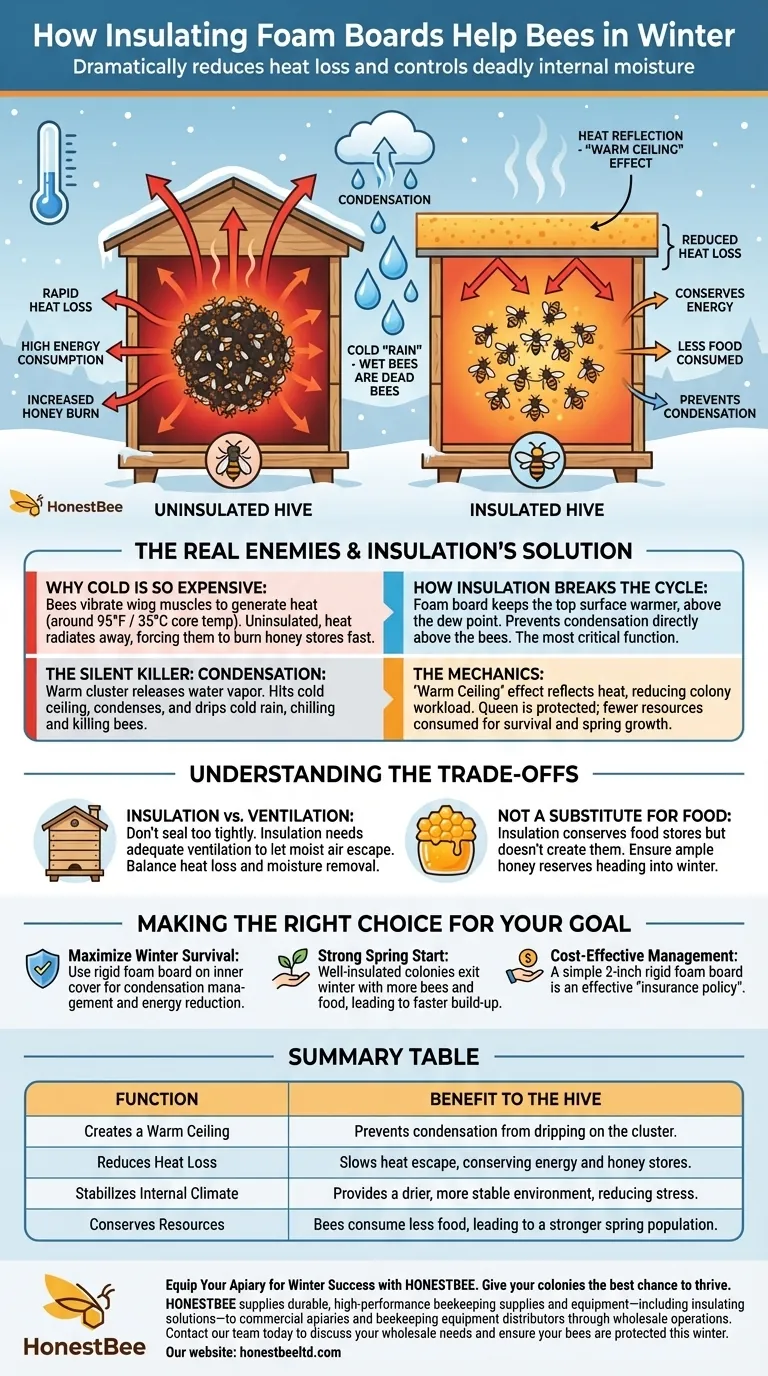

The Real Enemies of a Wintering Colony

To understand the value of insulation, we must first identify the two main threats bees face in winter: the energy cost of staying warm and the lethal effects of condensation.

Why Cold is So Expensive

Bees do not heat the entire hive. Instead, they form a tight cluster and vibrate their wing muscles to generate heat, maintaining a core temperature of around 95°F (35°C).

In an uninsulated hive, this heat radiates away quickly, especially through the top. This forces the bees to burn through their precious honey stores at an accelerated rate just to stay alive.

The Silent Killer: Condensation

As the bees metabolize honey and breathe, their warm cluster releases a significant amount of water vapor.

When this warm, moist air rises and hits a cold hive ceiling, it cools rapidly and condenses into water droplets. This cold "rain" can drip back down onto the cluster, chilling and killing the bees. Wet bees are dead bees.

How Insulation Breaks the Cycle

An insulating foam board, typically placed on top of the hive's inner cover, keeps that top surface warmer.

By keeping the inner lid above the dew point, condensation is prevented from forming directly above the bees. This is the single most important function of top insulation.

The Mechanics of Hive Insulation

Proper insulation is about managing heat flow and moisture, not just trapping heat. The placement and type of insulation are key.

The "Warm Ceiling" Effect

Think of the foam board as creating a warm ceiling. Most heat is lost vertically, so insulating the top of the hive is the most efficient way to reduce the colony's energy burden.

This simple addition acts as a thermal barrier, reflecting heat back down toward the cluster and stabilizing the hive's internal climate.

Reducing the Colony's Workload

By slowing heat loss, the insulation reduces the amount of work the bees must do. They consume less honey, experience less stress, and the queen is better protected within the core of the cluster.

This conservation of resources is crucial for not only surviving winter but also for having the population and energy needed for explosive growth in the spring.

Understanding the Trade-offs

Insulation is a powerful tool, but it must be applied with a clear understanding of the hive's ventilation needs.

Insulation vs. Ventilation

A common mistake is to seal a hive too tightly. Insulation must be paired with adequate ventilation to allow excess moist air to escape.

The goal is to prevent heat loss while still giving water vapor an exit path. Many beekeepers use a small upper entrance or vents in the hive body to achieve this balance.

It's Not a Substitute for Food

Insulation helps bees conserve their food stores, but it cannot create food. A colony's primary defense against winter is a hive packed with honey.

Always ensure your bees have more than enough food reserves heading into winter. Insulation is a supplemental strategy, not a replacement for proper feeding.

Making the Right Choice for Your Goal

Use these principles to guide your winterization strategy.

- If your primary focus is maximizing winter survival: Use a rigid foam board directly on the inner cover to manage condensation and reduce the colony's energy consumption.

- If your primary focus is a strong spring start: Recognize that a well-insulated colony exits winter with more bees and more food, enabling it to build up much faster once pollen is available.

- If your primary focus is cost-effective management: A simple piece of 2-inch thick rigid foam board is one of the cheapest and most effective "insurance policies" you can buy for your bees.

By controlling heat loss and moisture, you create a stable home where your colony can not only survive the winter but truly thrive.

Summary Table:

| Function | Benefit to the Hive |

|---|---|

| Creates a Warm Ceiling | Prevents condensation from dripping on the cluster, the primary cause of winter bee death. |

| Reduces Heat Loss | Slows heat escape through the hive top, allowing bees to conserve energy and honey stores. |

| Stabilizes Internal Climate | Provides a drier, more stable environment, reducing stress on the colony. |

| Conserves Resources | Bees consume less food to stay warm, leading to a stronger, larger population for spring. |

Equip Your Apiary for Winter Success with HONESTBEE

Give your colonies the best chance to thrive through the cold months and build up rapidly in the spring. HONESTBEE supplies durable, high-performance beekeeping supplies and equipment—including insulating solutions—to commercial apiaries and beekeeping equipment distributors through our wholesale-focused operations.

Contact our team today to discuss your wholesale needs and ensure your bees are protected this winter.

Visual Guide

Related Products

- Professional Insulated Plastic Bee Hives

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

- Langstroth Screen Bottom Board for Beekeeping Wholesale

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Australian Pine Wood Langstroth Screen Bottom Board for Wholesale

People Also Ask

- What are the advantages of plastic bee hives? Boost Efficiency & Durability for Your Apiary

- How much additional time does having more hives require? Master Efficient Apiary Management

- Why is it necessary to ensure a slight forward tilt when installing a beehive? Best Practices for Hive Drainage

- How does the longevity of plastic bee hives compare to wooden hives? Discover the Durable Choice

- Is polystyrene bee hive better than wood? Superior Insulation for Healthier Bees & More Honey