At its core, polyurethane foam resists environmental factors because it is a chemically inert synthetic polymer. This means it does not react with water, does not provide a food source for microbes, and possesses a stable structure that can withstand significant temperature fluctuations without decomposing, rusting, or breaking down like organic or metallic materials.

The key to polyurethane foam's durability is its inert nature. Its stable, non-reactive chemical structure makes it inherently resistant to the physical, biological, and chemical challenges posed by the environment.

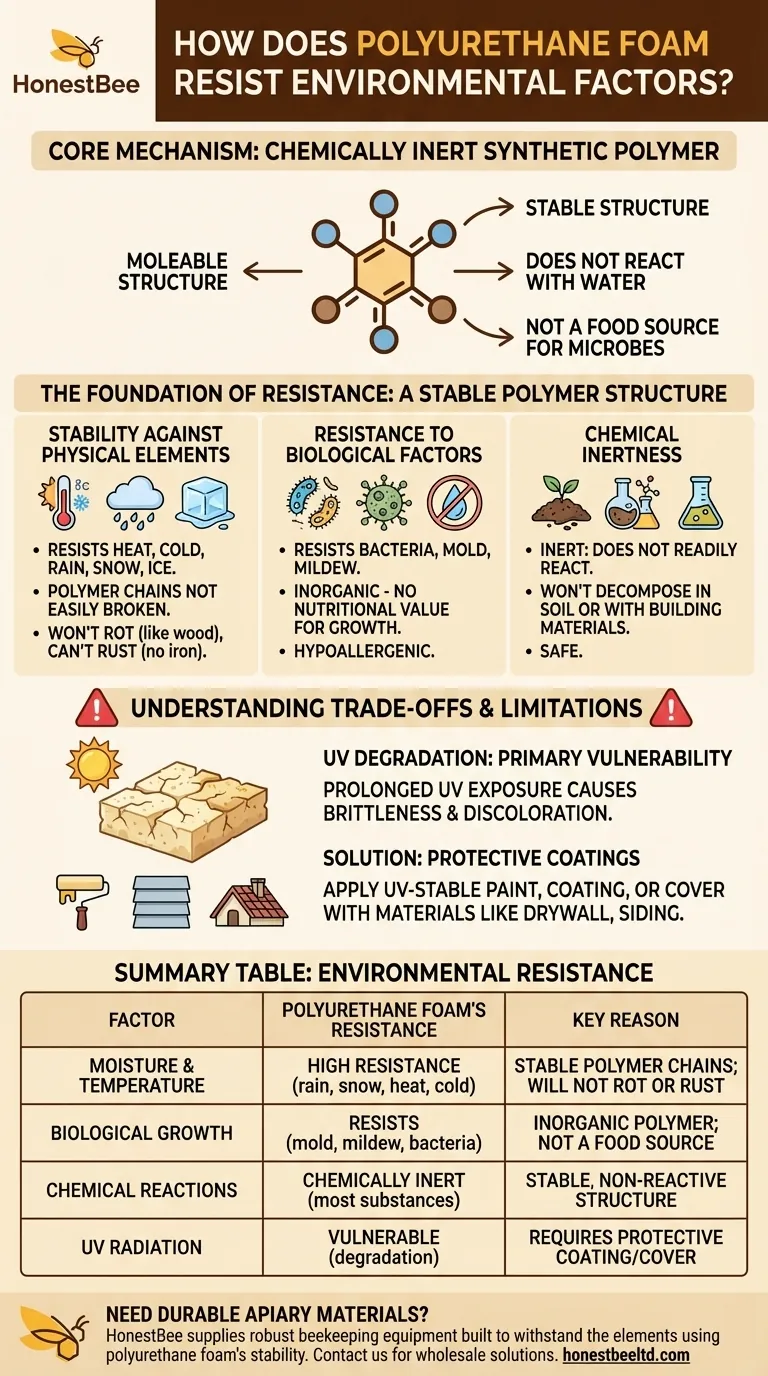

The Foundation of Resistance: A Stable Polymer Structure

The resilience of polyurethane foam is not a single feature but a result of its fundamental chemical composition. As a synthetic plastic, it behaves very differently from natural materials like wood or metal.

Stability Against Physical Elements

Polyurethane foam excels at resisting common physical stressors. It is highly resistant to heat, cold, rain, snow, and ice because its polymer chains are not easily broken down by temperature changes or moisture.

Unlike wood, it will not rot when wet. Unlike metal, it contains no iron and therefore cannot rust. This structural integrity ensures it maintains its form and insulating properties for decades.

Resistance to Biological Factors

Many materials fail because they are consumed by microorganisms. Polyurethane foam is resistant to bacteria, mold, and mildew for a simple reason: it is not a food source.

Being an inorganic polymer, it offers no nutritional value to support biological growth. This also contributes to it being hypoallergenic, as it does not harbor common allergens like mold spores.

Chemical Inertness Explained

The term "inert" is central to its performance. This means polyurethane foam does not readily participate in chemical reactions with other substances it might encounter.

It won't decompose when in contact with most soils or building materials. This stability is why it is often considered safe for sensitive applications, as it is unlikely to leach harmful substances into its surroundings once cured.

Understanding the Trade-offs and Limitations

No material is perfect. While polyurethane foam is incredibly resilient, a technical advisor must point out its primary vulnerability to ensure its proper application and longevity.

UV Degradation: The Primary Vulnerability

The single most significant environmental factor that affects polyurethane foam is ultraviolet (UV) radiation from direct sunlight.

Prolonged exposure will cause the outer surface of the foam to become brittle and turn a yellowish-brown color. This photodegradation can slowly compromise the material's surface integrity over time.

The Importance of Protective Coatings

Fortunately, protecting polyurethane foam from UV damage is straightforward. In nearly all standard applications, the foam is covered.

This is achieved by applying a UV-stable paint, coating, or by covering it with another building material like drywall, siding, or roofing materials. When protected from the sun, the foam's durability is maximized.

Making the Right Choice for Your Application

To decide if polyurethane foam is the correct material, you must align its properties with your project's primary goal.

- If your primary focus is long-term insulation and moisture control: Its resistance to water, temperature extremes, and decomposition makes it an exceptional choice, provided it is shielded from direct sunlight.

- If your primary focus is preventing mold and bacterial growth: Its inorganic and inert nature makes it a superior option compared to organic materials that can support and harbor microbial life.

- If your primary focus is environmental impact: You must weigh its long service life and high energy efficiency against the fact that it is a petroleum-based product with end-of-life disposal challenges.

Ultimately, polyurethane foam is a highly durable and reliable material when you manage its single weakness to UV exposure.

Summary Table:

| Environmental Factor | Polyurethane Foam's Resistance | Key Reason |

|---|---|---|

| Moisture & Temperature | High resistance to rain, snow, heat, and cold | Stable polymer chains; will not rot or rust |

| Biological Growth | Resists mold, mildew, and bacteria | Inorganic polymer; not a food source for microbes |

| Chemical Reactions | Chemically inert with most substances | Stable, non-reactive structure |

| UV Radiation | Vulnerable to degradation (brittleness, discoloration) | Requires a protective coating or cover |

Need durable, long-lasting materials for your apiary or distribution business? The inherent stability and environmental resistance of polyurethane foam make it an ideal component for high-quality beekeeping equipment. At HONESTBEE, we supply commercial apiaries and distributors with robust supplies built to withstand the elements. Contact our experts today to discuss wholesale solutions that offer superior durability and performance for your customers.

Visual Guide

Related Products

- Inner Beehive Cover for Beekeeping Bee Hive Inner Cover

- Professional Beekeeping Suit for Kids and Girls Childrens Bee Keeper Suit

- Professional Grade Foldable Beehive Handles

- Black Plastic Beetle Barn Hive Beetle Trap for Beehives

- HONESTBEE Professional Telescopic Pole Bee Swarm Catcher

People Also Ask

- Why might beekeepers use an inner cover under the telescoping outer cover? Simplify Hive Management & Protect Your Colony

- What are the advantages of using an inner cover in a beehive? Key Benefits for Hive Health & Beekeeper Efficiency

- What is the role of inner covers in insulated beehives? Master Moisture Control for a Healthy Colony

- What is the function of the center hole in the inner cover? Master Hive Ventilation and Feeding

- How should the inner cover be positioned in a beehive? A Seasonal Guide for Hive Health