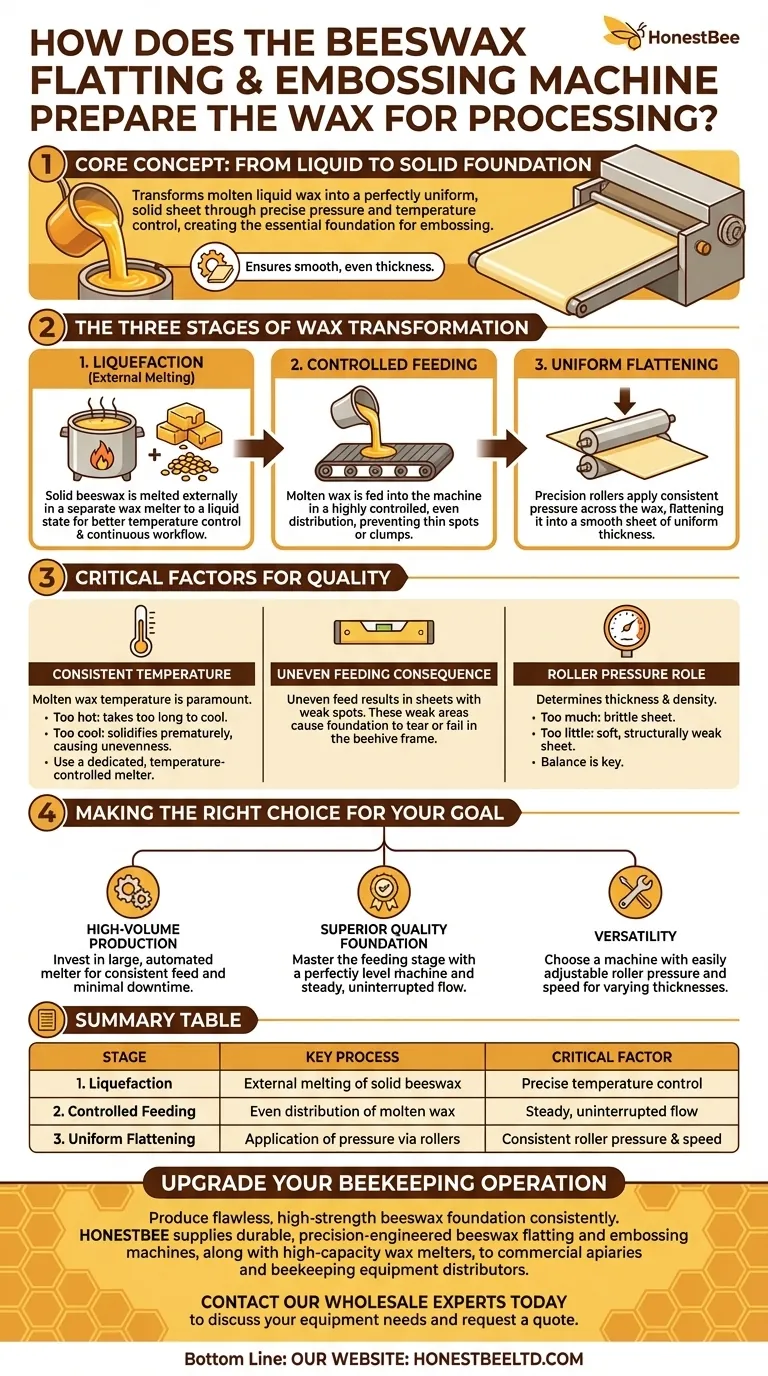

At its core, a beeswax flatting and embossing machine prepares wax for processing by transforming it from a molten liquid into a perfectly uniform, solid sheet. It accomplishes this by first carefully feeding the liquid wax onto a surface and then applying precise pressure with rollers or a press to achieve a consistent thickness.

The machine's primary function is not to melt the wax, but to control its transition from a liquid to a solid state. It ensures the creation of a smooth, even sheet, which is the essential foundation for subsequent embossing.

The Three Stages of Wax Transformation

To understand how the machine prepares the wax, it's best to view the process in three distinct stages. This entire workflow is designed to move from raw beeswax to a perfectly formed, workable sheet.

Stage 1: Liquefaction (External Melting)

The process begins before the wax even enters the machine. Solid beeswax, either in blocks or pellets, must first be melted into a liquid state.

This critical step is handled by a separate wax melter or heating device. Keeping the melting process external allows for better temperature control and enables a continuous workflow.

Stage 2: Controlled Feeding

Once the beeswax is molten, it is introduced into the flatting and embossing machine. This is the feeding stage.

The machine's system is designed to pour or feed the liquid wax in a highly controlled manner, ensuring an even distribution across a flat surface or a moving conveyor belt. This prevents thin spots or clumps from forming.

Stage 3: Uniform Flattening

This is where the machine performs its primary shaping function. The evenly distributed layer of molten wax moves toward a pressure mechanism.

Using a set of precision rollers or a press, the machine applies consistent pressure across the entire width of the wax. This action flattens the wax into a smooth sheet of uniform thickness, ready for embossing or other uses.

Understanding the Critical Factors

The quality of the final beeswax sheet is not automatic. It depends on carefully managing several key variables in the process. A failure at any stage will compromise the end result.

The Importance of Consistent Temperature

The temperature of the molten wax when it's fed into the machine is paramount. If the wax is too hot, it may take too long to cool. If it's too cool, it can solidify prematurely, leading to an uneven sheet.

Using a dedicated, temperature-controlled melter gives you the granular control needed to feed the wax at the optimal temperature for your specific machine and environmental conditions.

The Consequence of Uneven Feeding

The goal of the feeding stage is a perfectly level layer of liquid wax. Any inconsistency here will be magnified during the flattening stage.

An uneven feed results in a final sheet with thick and thin spots. These weaker areas can cause the beeswax foundation to tear or fail when installed in a beehive frame.

The Role of Roller Pressure

The pressure exerted by the rollers determines the final thickness and density of the sheet. Most machines allow for this to be adjusted.

Too much pressure can make the sheet brittle, while too little can result in a soft sheet that lacks structural integrity. Finding the right balance is key to producing a high-quality product.

Making the Right Choice for Your Goal

Understanding this process allows you to optimize your operation based on your specific needs, whether you are producing foundation for your own hives or for commercial sale.

- If your primary focus is high-volume production: Invest in a large, automated melter that can consistently feed molten wax to your machine, minimizing downtime.

- If your primary focus is superior quality foundation: Master the feeding stage by ensuring your machine is perfectly level and the wax flow is steady and uninterrupted.

- If your primary focus is versatility: Choose a machine with easily adjustable roller pressure and speed to produce sheets of varying thicknesses for different applications.

By controlling each stage of this transformation, you gain complete authority over the quality and consistency of your final beeswax products.

Summary Table:

| Stage | Key Process | Critical Factor |

|---|---|---|

| 1. Liquefaction | External melting of solid beeswax | Precise temperature control |

| 2. Controlled Feeding | Even distribution of molten wax | Steady, uninterrupted flow |

| 3. Uniform Flattening | Application of pressure via rollers | Consistent roller pressure & speed |

Upgrade Your Beekeeping Operation with Professional-Grade Equipment

Produce flawless, high-strength beeswax foundation consistently. HONESTBEE supplies durable, precision-engineered beeswax flatting and embossing machines, along with high-capacity wax melters, to commercial apiaries and beekeeping equipment distributors.

Let us help you increase your production volume and product quality. Contact our wholesale experts today to discuss your equipment needs and request a quote.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Mini Desktop Bee Hive Frame Forming Making Machine

People Also Ask

- What is the purpose of the hot water bath in the process of making wax foundation? Ensure Clean Release & Quality

- How are intricate designs applied to the beeswax sheet by the machine? Mastering Precision Embossing Techniques

- How does the machine flatten the beeswax? A Guide to Roller and Press Methods

- What are the castings of the beeswax foundation machine made of? Precision Engineering for Efficient Beekeeping

- What is the purpose of using soap and suds on the roller? Ensure a Clean, Tear-Free Wax Sheet Release

- What customization options are available with fully automatic wax foundation machines? Tailor Sheets for Any Hive Frame

- What is the ideal room temperature for milling wax foundation? Expert Tips for Perfect Thermal Management

- What role do beeswax foundation machines play in modern bee colony expansion? Maximize Apiary Efficiency & Growth