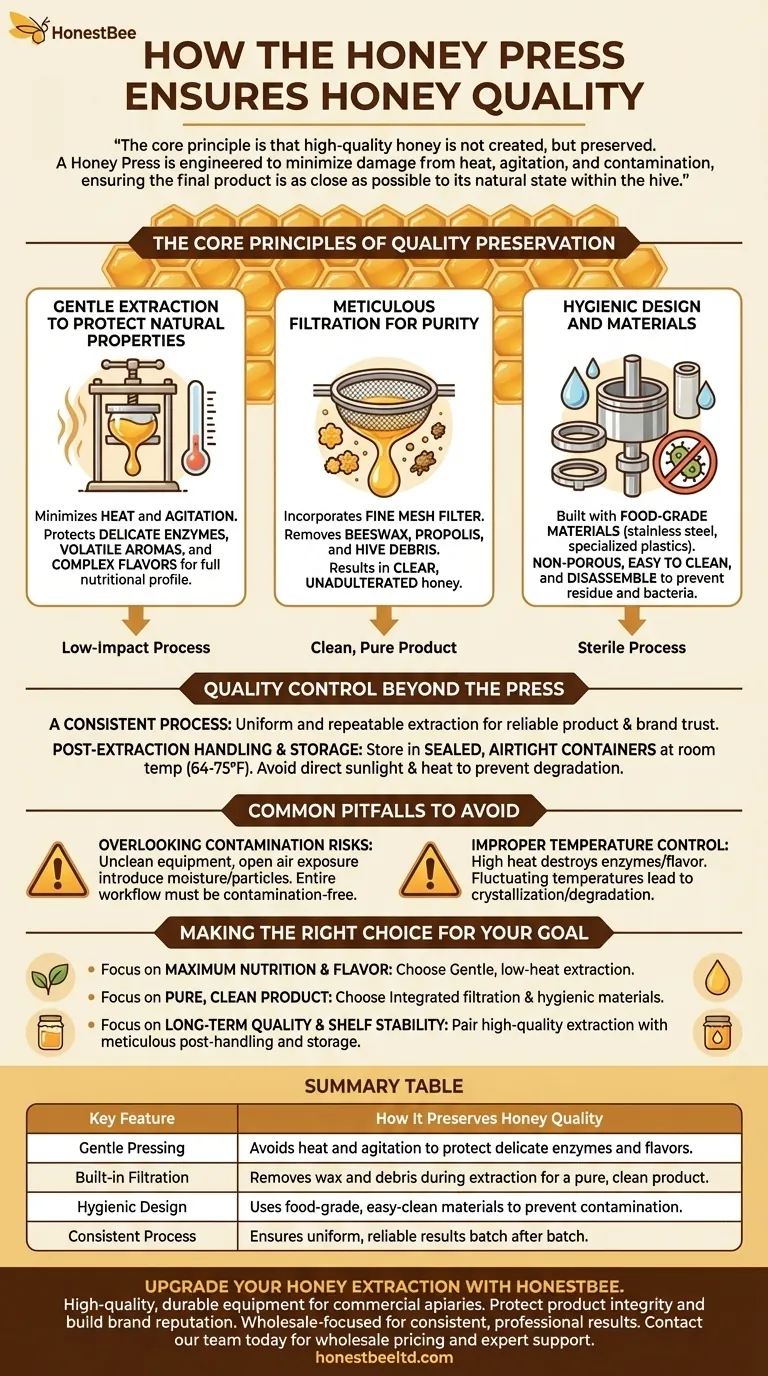

The Honey Press ensures honey quality through a combination of three key factors: a gentle extraction method that preserves the honey's natural properties, a built-in filtration system for purity, and a design that prioritizes hygiene to prevent contamination. This approach protects the honey's delicate enzymes and flavors from the moment it leaves the comb.

The core principle is that high-quality honey is not created, but preserved. A Honey Press is engineered to minimize damage from heat, agitation, and contamination, ensuring the final product is as close as possible to its natural state within the hive.

The Core Principles of Quality Preservation

The quality of extracted honey is directly tied to how it is handled. A Honey Press focuses on a low-impact process that protects the product at every stage.

Gentle Extraction to Protect Natural Properties

The primary mechanism is a gentle pressing technique. This method minimizes the two main enemies of raw honey quality: heat and agitation.

By avoiding high speeds or friction, the press protects the delicate enzymes, volatile aromas, and complex flavors that define premium honey. This is crucial for preserving its full nutritional profile.

Meticulous Filtration for Purity

The press incorporates a fine mesh filter directly into the extraction workflow. This is a critical step for ensuring a clean, pure product.

As honey is extracted, the filter immediately removes unwanted particles like beeswax, propolis, and other hive debris. This results in clear, unadulterated honey that is ready for bottling.

Hygienic Design and Materials

To prevent contamination, the Honey Press is built with food-grade materials, such as stainless steel and specialized plastics.

These materials are non-porous and easy to clean, ensuring that no residue or bacteria from previous batches can compromise the next. The ability to easily disassemble and rinse the parts is fundamental to maintaining a sterile process.

Quality Control Beyond the Press

While the press is central to extraction, maintaining quality involves a broader system of control, from the process itself to how the honey is handled afterward.

The Importance of a Consistent Process

A well-designed press provides a uniform and repeatable extraction process. This consistency is vital for beekeepers who need to deliver a standard, reliable product to consumers.

When the quality is dependable batch after batch, it helps build a reputable brand and consumer trust.

Post-Extraction Handling and Storage

The job is not finished once the honey leaves the press. Proper storage is essential to preserve the quality that the extraction process protected.

Honey must be stored in sealed, airtight containers at room temperature (around 64-75°F). It should be kept away from direct sunlight and heat sources to prevent degradation of its flavors and beneficial properties.

Common Pitfalls to Avoid

Even with excellent equipment, simple mistakes can compromise honey quality. Understanding these potential issues is key to producing a superior product.

Overlooking Contamination Risks

Contamination can happen at any stage. Using equipment that is not thoroughly cleaned or allowing honey to be exposed to open air for extended periods can introduce moisture or foreign particles.

The entire workflow, from extraction to bottling, must be a clean, contamination-free process to preserve the freshness and purity of the honey.

Improper Temperature Control

Exposing honey to high heat, even for a short time, can destroy its beneficial enzymes and alter its flavor. Likewise, storing it in a location with fluctuating temperatures can lead to crystallization or degradation.

The gentle, low-heat nature of a honey press is its main advantage, but that benefit is lost if the honey is not stored correctly afterward.

Making the Right Choice for Your Goal

Your primary objective will determine which aspects of the quality process you emphasize most.

- If your primary focus is preserving maximum nutritional value and flavor: A Honey Press is an ideal choice due to its exceptionally gentle, low-heat extraction method.

- If your primary focus is creating a pure, clean, and professional product: The integrated filtration and hygienic, food-grade materials of the press are its most critical features.

- If your primary focus is long-term quality and shelf stability: You must pair a high-quality extraction method with meticulous post-extraction handling, especially airtight storage at a stable room temperature.

Ultimately, a Honey Press provides the foundation for quality by ensuring the extraction itself does no harm.

Summary Table:

| Key Feature | How It Preserves Honey Quality |

|---|---|

| Gentle Pressing | Avoids heat and agitation to protect delicate enzymes and flavors. |

| Built-in Filtration | Removes wax and debris during extraction for a pure, clean product. |

| Hygienic Design | Uses food-grade, easy-clean materials to prevent contamination. |

| Consistent Process | Ensures uniform, reliable results batch after batch. |

Upgrade Your Honey Extraction with HONESTBEE

As a trusted supplier for commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the high-quality, durable equipment you need to protect your product's integrity and build your brand's reputation. Our wholesale-focused operations ensure you get the reliable tools for a consistent, professional result.

Let's discuss how our honey presses and supplies can enhance your operation. Contact our team today for wholesale pricing and expert support.

Visual Guide

Related Products

- Commercial 48-Frame Stainless Steel Honey Extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- 24 Frame Honey Extractor Commercial Radial Honey Frame Extraction Machine

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- What are the benefits of the Honey Press's gentle extraction method? Preserve Raw Honey Quality and Bee Welfare

- How does a honey press work? A Guide to Simple, High-Yield Honey Extraction

- Why are honey presses considered valuable for beekeepers? Maximize Honey & Wax Yield Efficiently

- How does a honey press help beekeepers meet the demand for chunk honey? Craft Authentic, Raw Hive Products

- How can one safely handle the sharp edges of a new steel press? Preparation Tips for Beekeeping Tools

- What is the process for cleaning a honey press after use? Ensure Purity & Protect Your Equipment

- What is the proper method for cleaning a honey press? Maintain Hygiene and Equipment Longevity

- What steps are involved in operating a bucket honey press? A Simple Guide for Small-Scale Beekeepers