Using a honey press makes the honeycomb entirely non-reusable. The process, known as "crush and strain," works by physically crushing the comb to squeeze out the honey. This destructive method means the bees must completely rebuild the comb from scratch for the next honey flow, a key consideration for any beekeeper.

A honey press trades the reusability of comb for other distinct advantages. While it slows down future honey production, it excels at producing high-quality beeswax and preserving the unique, natural characteristics of the honey, making it a strategic choice for certain beekeeping goals.

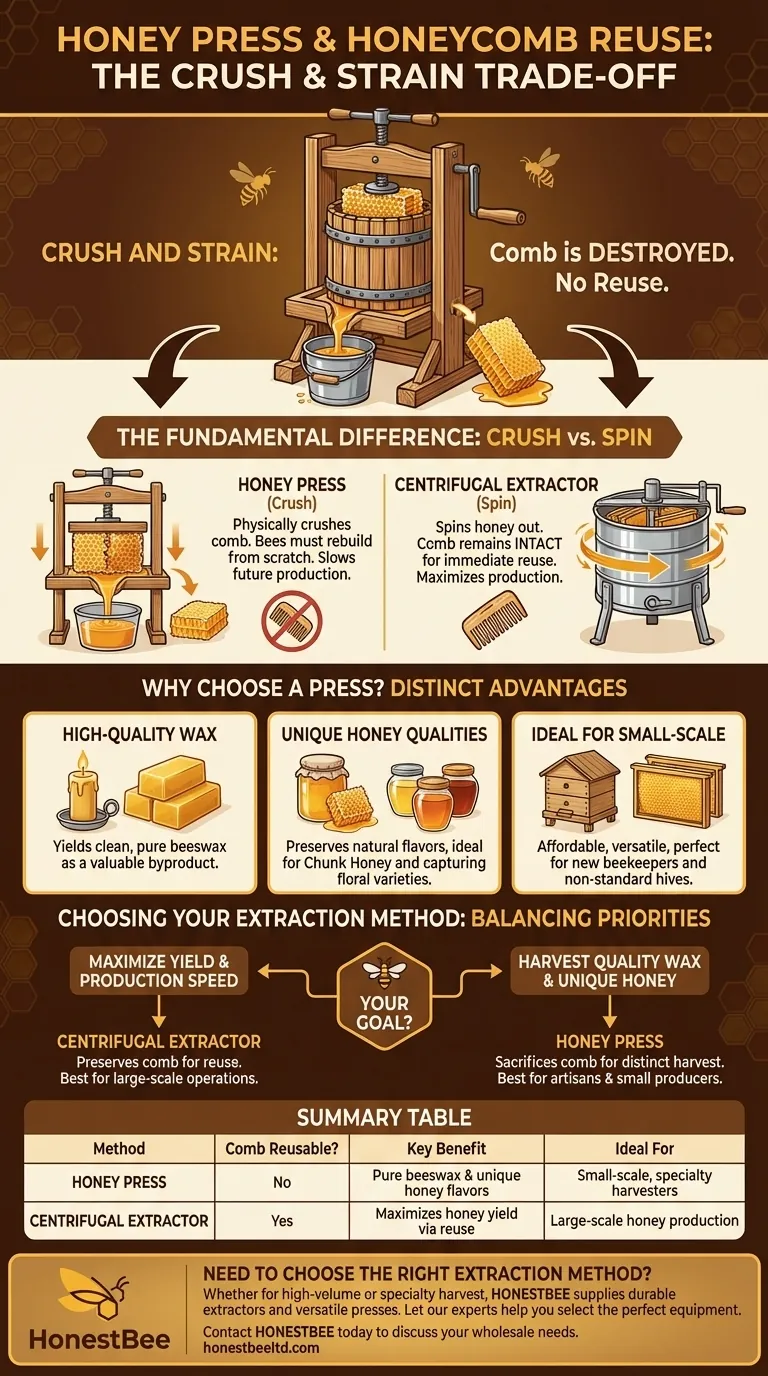

The Fundamental Difference: Crush vs. Spin

Understanding the impact of a honey press begins with contrasting it against the primary alternative, the centrifugal extractor. Each method operates on a completely different principle, leading to different outcomes for both the beekeeper and the bees.

How a Honey Press Works

A honey press is a simple mechanical device that applies pressure to the honeycomb. The comb is cut from its frame and placed inside the press, which then squeezes it. The honey runs out and is collected, leaving behind a compressed block of pure beeswax.

This method is direct, effective, and ensures minimal honey is left behind in the comb.

The Consequence: No Comb Reuse

The key drawback is that this process completely destroys the comb's structure. Bees expend a significant amount of energy and resources to produce wax and build these intricate hexagonal cells.

When a beekeeper returns an intact, empty comb to the hive after extraction, the bees can immediately begin refilling it with nectar. By destroying the comb, you force the bees to restart this time-consuming construction process, effectively slowing down your potential honey production.

The Alternative: Centrifugal Extraction

Centrifugal extractors, whether manual or electric, work by spinning frames at high speed. This force slings the honey out of the cells while leaving the delicate wax comb intact.

These preserved combs can be returned to the hive for immediate reuse. However, it's worth noting that even this method is not without risk; starting an electric extractor too fast can sometimes damage and break the comb.

Why Choose a Press if It Destroys the Comb?

If centrifugal extraction is more efficient for honey production, the decision to use a honey press comes down to its unique set of benefits that appeal to a different set of priorities.

Benefit 1: High-Quality Wax as a Byproduct

The crush and strain method is not just about honey; it's also an excellent way to harvest wax. The process naturally separates the honey from the wax, yielding clean, pure beeswax that can be used for candles, balms, or other valuable products.

Benefit 2: Preserving Honey's Natural Qualities

Many enthusiasts believe pressing produces a more "natural" or "less refined" honey. It is the ideal method for creating chunk honey (where a piece of comb is included in the jar) and for capturing subtle flavor variations.

By pressing and bottling honey from individual combs, you can taste the unique floral sources the bees were visiting at different times, resulting in a variety of flavors from a single hive.

Benefit 3: Ideal for Small-Scale and Specialty Operations

Honey presses are often smaller, more affordable, and more versatile than extractors. They are perfect for new beekeepers, those with only a few hives, or those using non-standard frames (like in a Warre hive) that don't fit in a conventional extractor.

Understanding the Trade-offs

Choosing your extraction method is a matter of weighing competing priorities. There is no single "best" tool, only the right tool for a specific goal.

Production Efficiency vs. Product Quality

This is the central trade-off. A centrifugal extractor prioritizes production speed by preserving the comb for reuse. A honey press prioritizes the unique qualities of the harvest, delivering distinct honey flavors and high-grade beeswax at the cost of production efficiency.

Scale of Operation

For large-scale honey production where volume is the primary goal, the time saved by reusing comb makes a centrifugal extractor the only practical choice. For hobbyists or small-scale producers, the benefits of a press often outweigh the loss of comb.

Labor and Time Investment

While simple, using a press can be more labor-intensive and time-consuming per frame than using an electric extractor. Cutting comb, pressing it, and handling the resulting wax requires more manual steps.

Making the Right Choice for Your Apiary

Your decision should be guided by what you want to achieve with your beekeeping.

- If your primary focus is maximizing honey yield and production speed: A centrifugal extractor is the superior choice because it preserves the comb for immediate reuse by the bees.

- If your primary focus is harvesting high-quality beeswax and unique honey: A honey press is ideal, as it perfectly separates pure wax and allows you to capture distinct flavor profiles from individual combs.

- If you are a new beekeeper, have a small-scale operation, or use non-standard hives: The affordability, small footprint, and versatility of a honey press make it an excellent and practical starting point.

Ultimately, the right tool depends on whether you are optimizing for production volume or the unique qualities of your harvest.

Summary Table:

| Method | Comb Reusable? | Key Benefit | Ideal For |

|---|---|---|---|

| Honey Press | No | Yields pure beeswax & unique honey flavors | Small-scale, specialty honey, wax harvesters |

| Centrifugal Extractor | Yes | Maximizes honey yield via comb reuse | Large-scale honey production |

Need to Choose the Right Extraction Method for Your Apiary?

Whether you're a commercial apiary focused on maximizing honey yield or a distributor supplying beekeepers with the right tools, HONESTBEE has the solution. We supply durable, efficient centrifugal extractors for high-volume production and versatile honey presses for harvesting premium wax and unique honey varieties.

Let our experts help you select the perfect equipment to meet your specific goals. Contact HONESTBEE today to discuss your needs and get a quote on our wholesale-focused beekeeping supplies and equipment.

Visual Guide

Related Products

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Stainless Steel Honey Press Wax Press with Tank

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- How should a honey press be cleaned after it has been used? Essential Maintenance Tips for Your Harvest Tools

- What is a Honey Press and what are its alternative names? Discover the Best Manual Extraction Methods

- How does the honey pressing method offer flexibility in hive management regarding comb structure? Simplify Your Harvest

- What is the purpose of a honey press? Maximize Yield for Small-Scale Beekeeping

- How can the use of specialized beekeeping hardware like propolis grids and wax presses improve production? Scale Now

- What are the benefits of pressing honeycomb for honey harvesting? Maximize Bioactivity and Artisanal Quality

- What is the best time of year to separate beeswax from honey? Optimize Your Harvest for Maximum Yield

- Can a honey press be used for other purposes? 3 Versatile Uses for Beekeepers and Hobbyists