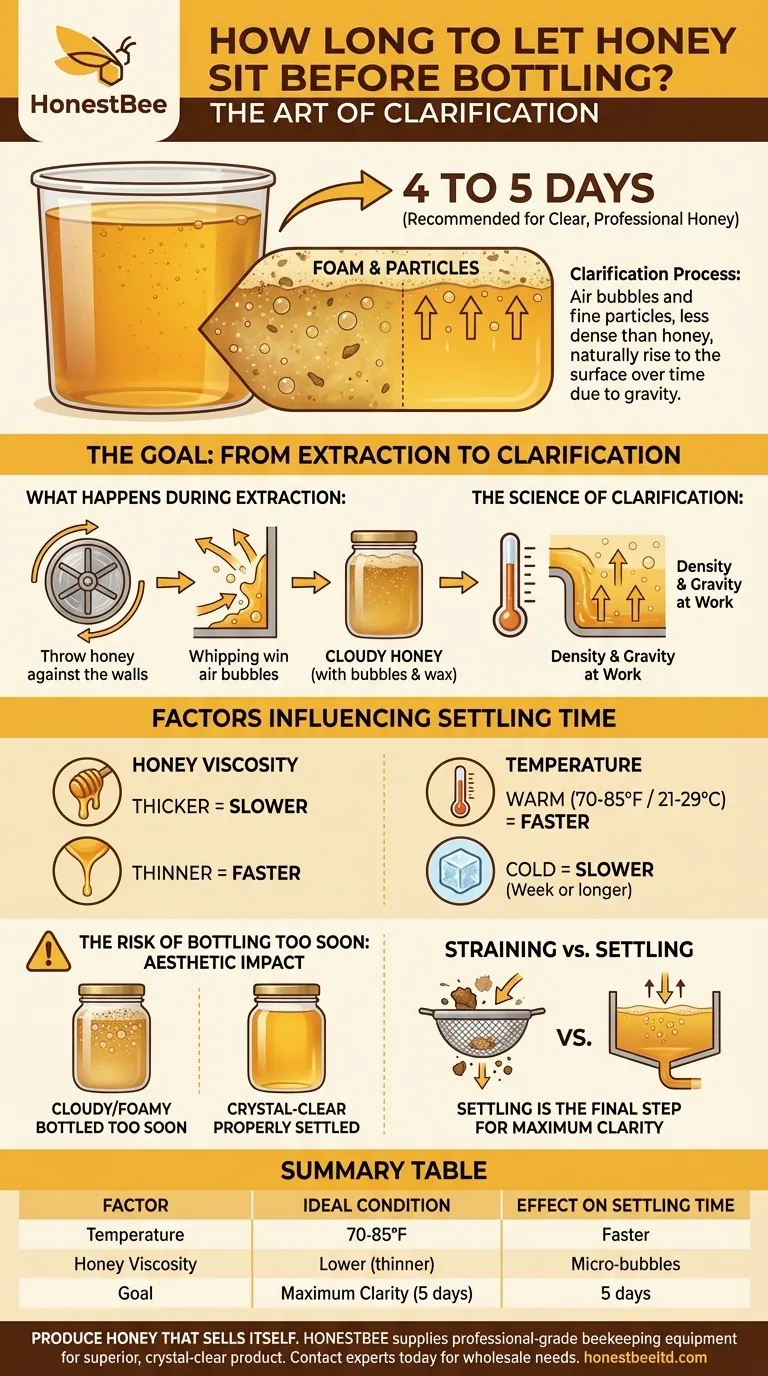

For clear, professional-looking honey, you should let it settle for approximately 4 to 5 days before bottling. This settling period is a critical step known as clarification. It allows air bubbles and small particles introduced during the extraction process to naturally rise to the surface, resulting in a beautifully clear final product.

The waiting period before bottling isn't arbitrary; it's a necessary process driven by gravity. By allowing honey to settle, you are removing the air bubbles and fine particulates whipped into it during extraction, ensuring a crystal-clear and high-quality product ready for the jar.

The Goal of Settling: From Extraction to Clarification

After you extract honey from the comb, it's often cloudy and contains significant amounts of trapped air. The settling process is designed to correct this before the honey is sealed in a jar.

What Happens During Extraction

The process of spinning frames in an extractor forcefully throws honey against the walls of the drum. This action inevitably whips air into the honey, creating countless tiny bubbles. These bubbles, along with any fine wax particles, are what make freshly extracted honey appear cloudy or foamy.

The Science of Clarification

Clarification relies on a simple principle: density. Air bubbles and most fine wax particles are less dense than the honey itself.

Given time, gravity will cause these lighter elements to slowly float to the top. The honey at the bottom of your tank will become progressively clearer as the bubbles complete their journey to the surface.

Skimming the Foam

After 4 to 5 days, you will see a layer of foam, bubbles, and wax particles on the surface of the honey. This layer should be carefully skimmed off before you begin bottling. Most bottling buckets have a spigot or "honey gate" near the bottom, allowing you to drain the clear honey from below the surface foam.

Factors That Influence Settling Time

While 4 to 5 days is an excellent rule of thumb, a few variables can affect the ideal settling time for your specific batch of honey.

Honey Viscosity

Not all honey is the same. Thicker, more viscous honey (often with a lower moisture content) will slow the ascent of air bubbles. Thinner, runnier honey will clarify more quickly.

Temperature

Temperature is the most significant factor you can control. Warm honey is less viscous, allowing bubbles to rise much faster. Storing your bottling tank in a warm room (ideally 70-85°F or 21-29°C) will significantly speed up clarification. Cold honey can take a week or longer to settle properly.

Understanding the Trade-offs

Rushing or mishandling the settling process can impact your final product. Understanding the potential pitfalls ensures you get the results you want.

The Risk of Bottling Too Soon

The primary consequence of bottling honey before it has fully settled is aesthetic. Your jars will contain trapped air bubbles, giving the honey a foamy or cloudy appearance. While perfectly safe to eat, it can be perceived as lower quality by customers or gift recipients.

A Note on Filtering vs. Settling

Straining (or filtering) and settling are two different steps that achieve different goals. Straining, typically done as honey flows out of the extractor, uses a mesh to remove large debris like wax chunks and bee parts.

Settling is the more patient, final step that removes the micro-bubbles and very fine particles that pass through even a fine-mesh strainer. For the clearest honey, you should do both.

Making the Right Choice for Your Goal

Use the settling time to achieve your desired outcome for the final product.

- If your primary focus is maximum clarity: Let the honey settle for the full 5 days in a warm room, and be meticulous when skimming the surface before opening the honey gate.

- If your primary focus is speed: Settle for at least 3 days in a very warm environment (around 85°F / 29°C), but understand you may still have some persistent micro-bubbles in the final product.

- If you are dealing with very thick honey: Prioritize keeping the honey warm to reduce its viscosity and consider extending the settling time to 6 days to ensure all bubbles have risen.

Patience during the settling phase is the final, crucial step in producing truly exceptional honey.

Summary Table:

| Factor | Ideal Condition | Effect on Settling Time |

|---|---|---|

| Temperature | 70-85°F (21-29°C) | Warmer = Faster clarification |

| Honey Viscosity | Lower (thinner honey) | Thinner = Faster clarification |

| Goal | Maximum Clarity | 5 days is recommended |

Produce Honey That Sells Itself

For commercial apiaries and distributors, the clarity of your honey directly impacts its marketability and perceived value. HONESTBEE supplies the professional-grade beekeeping supplies and equipment—from settling tanks to honey gates—that ensure your bottling process is efficient and yields a superior, crystal-clear product.

Let us help you scale your operation with reliable, wholesale-focused equipment. Contact our experts today to discuss your specific needs and streamline your honey production.

Visual Guide

Related Products

- Squeezable No-Drip Beehive-Shaped Honey Jars with Flip-Top Cap

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Classic Honey Bear Jars with Flip Top Dispensing Cap for Liquid Sweeteners

- Classic Drum Shaped Glass Honey Jar with Airtight Lid

People Also Ask

- What is the technical significance of industrial honey-filling machines in the development of honey resources?

- What role does precision filling equipment play in cost control? Maximize Honey Profits & Market Growth

- How do high-precision honey filling machines manage diverse SKU requirements? Optimize Production with Flexible Tooling

- What technical advantages do honey-filling machines provide? Boost Efficiency with Precision Automation

- What role do automated filling and packaging machines play in the honey supply chain? Scale Your Retail Distribution

- Why is automated honey-filling machinery essential? Drive Industrial Efficiency and Global Export Compliance

- Why is professional honey filling machinery necessary for the commercialization of organic honey? Ensure Purity and Scale

- Why is specialized filling and packaging equipment indispensable for the honey export industry? Win Global Markets