To properly clean a honey press, you must disassemble it and wash all components with warm water and a food-safe detergent. This process ensures the removal of honey residue and wax particles. For stubborn wax, a more intensive method involving boiling water may be necessary to soften the material before scraping it off.

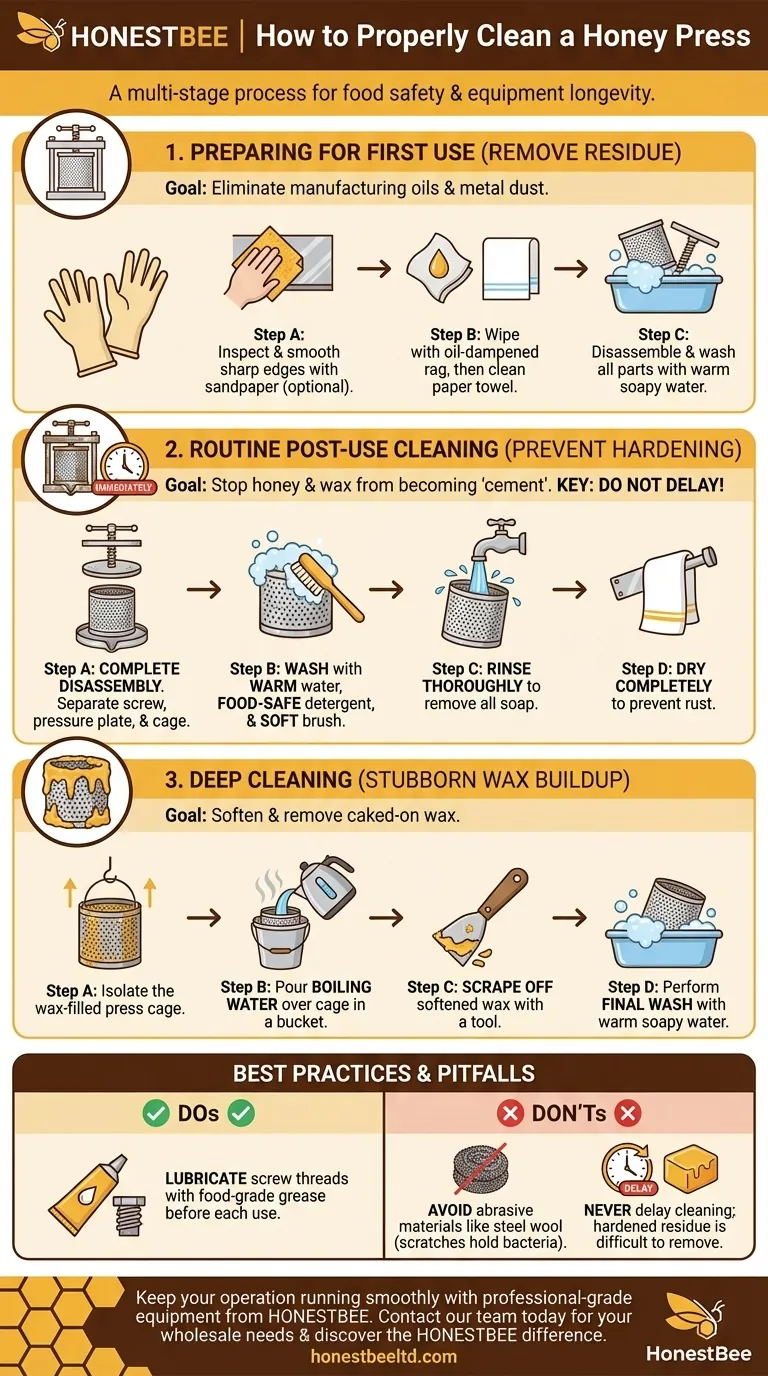

The core principle of honey press maintenance is that cleaning is not a single action, but a multi-stage process. Effective cleaning involves a specific preparation for first-time use, a consistent routine after every extraction, and a deep-cleaning method for stubborn wax buildup.

Preparing a New Honey Press for First Use

Before its first run, a new honey press requires a thorough cleaning to remove manufacturing residues. This initial preparation is critical for ensuring the safety and purity of your honey.

Why Initial Cleaning is Non-Negotiable

New equipment often carries residual oils, metal dust, or welding residues from the manufacturing process. A simple rinse is insufficient; these contaminants must be washed away completely with a detergent solution to avoid tainting your honey.

The Optional Sanding Step

For safety and longevity, inspect the press for any sharp metal edges. Wearing protective gloves, you can smooth these areas with 400 to 600-grit sandpaper. This prevents cuts during handling and cleaning.

The First Wash

After any sanding, wipe the entire press with a rag dampened in vegetable oil, then with a clean paper towel. This helps capture any fine metal dust. Finally, disassemble the press and thoroughly wash every component with warm water and food-safe soap to remove all oils and debris.

The Standard Post-Use Cleaning Routine

Cleaning the press immediately after use is the most effective way to prevent honey and wax from hardening, which makes the task significantly more difficult.

Disassembly for Thoroughness

Honey presses are designed to be easily taken apart. Unwind the press screw, remove the pressure plate, and take out the cage or basket. Separating these components is the only way to ensure you can clean every surface that came into contact with honey.

Washing with Warm Water and a Soft Brush

Use warm water, a food-safe detergent, and a soft nylon brush to scrub all parts. The gentle bristles can get into the perforations of the press cage without scratching the metal.

Rinsing and Drying Completely

Rinse every component with clean water until all soap residue is gone. Thoroughly dry the press with a clean cloth before reassembly. Proper drying is crucial for preventing rust on any steel parts and ensuring the press is ready for its next use.

Deep Cleaning: Removing Stubborn Wax Buildup

When you've pressed honey from crushed comb, you will be left with significant wax residue. A standard wash may not be enough to remove it all.

Step 1: Isolate the Press Cage

After unwinding the press, remove the steel cage containing the compressed wax. Place this cage inside a bucket suitable for handling high temperatures.

Step 2: Use Boiling Water to Soften Wax

Carefully pour boiling water over the cage. The heat will quickly soften the hardened wax, causing it to release its grip on the metal.

Step 3: Scrape and Rinse

Once the wax is soft, use a scraper to remove the bulk of it from the cage. You can add cold water to the bucket, which will cause the remaining wax in the water to solidify for easy removal and later rendering.

Step 4: Perform a Final Wash

After the majority of the wax is gone, proceed with the standard cleaning routine. Wash the cage and all other parts of the press with warm water and detergent to remove any final waxy or honey residue. Dry completely and reassemble.

Best Practices and Common Pitfalls

Proper maintenance goes beyond just washing. A few key practices will extend the life of your press and improve its performance.

Avoid Abrasive Materials

Never use steel wool or harsh scouring pads. These can scratch the surface of the press, creating small crevices where bacteria can grow and making future cleaning more difficult.

Consider Pre-Use Lubrication

Oiling the screw threads with a food-grade grease or oil before each use is a common recommendation. This not only makes pressing smoother and easier but also simplifies the cleanup process afterward.

Never Delay Cleaning

The single biggest mistake is letting the press sit after use. Honey and wax will harden into a difficult-to-remove cement. Cleaning immediately when the residues are still soft will save you considerable time and effort.

Matching Your Cleaning to the Task

Your approach to cleaning should match the situation to ensure both food safety and the longevity of your equipment.

- If you are using a press for the very first time: Your priority is a deep initial clean with detergent to remove all manufacturing oils and residues.

- If you are performing a routine cleaning after pressing honey: Focus on immediate disassembly and a thorough wash with warm, soapy water before any residue has a chance to harden.

- If you are dealing with significant, caked-on wax: Use the boiling water method to soften and scrape away wax before you proceed with a standard detergent wash.

A clean, well-maintained press is a reliable tool that ensures the purity of your honey harvest after harvest.

Summary Table:

| Cleaning Scenario | Primary Goal | Key Steps |

|---|---|---|

| First-Time Use | Remove manufacturing residues | Disassemble, wash with detergent, optional sanding |

| Routine Post-Use | Prevent honey/wax hardening | Immediate disassembly, wash with warm soapy water, dry thoroughly |

| Deep Clean (Wax Buildup) | Remove caked-on wax | Use boiling water to soften wax, scrape, then standard wash |

Keep your operation running smoothly with professional-grade equipment from HONESTBEE.

Proper cleaning is essential, but it starts with a durable, well-designed honey press. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, easy-to-maintain beekeeping supplies and equipment through our wholesale-focused operations.

Let us help you equip your business for efficiency and success. Contact our team today to discuss your wholesale needs and discover the HONESTBEE difference.

Visual Guide

Related Products

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Stainless Steel Honey Press Wax Press with Tank

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 10L Stainless Steel Electric Honey Press Machine

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- What is the primary function of mechanical pressing equipment in DSM production? Boost Hive Health Naturally

- For which beekeeping methods are honey presses particularly useful? Expert Extraction Guide

- What is the importance of a cappings press in honey processing? Maximize Yield and Efficiency for Your Apiary

- How should a honey press be cleaned after use? Essential Hygiene & Wax Recovery Tips

- What types of beehive frames are compatible with the honey press? A Guide to Crush-and-Strain Extraction

- How does the honey screw press operate? A Guide to Maximizing Honey Yield from Cappings

- What are the benefits of the Honey Press's gentle extraction method? Preserve Raw Honey Quality and Bee Welfare

- Why is a honey press suitable for producing chunk honey? Achieve Authentic, Natural Honey for Your Customers