Properly maintaining honey filtering equipment is a systematic process centered on four key actions: immediate cleaning, thorough drying, regular filter inspection, and periodic system checks. This routine is essential for preventing residue buildup and corrosion, which directly extends the life of your equipment and, more importantly, preserves the natural quality of your honey.

The goal of equipment maintenance is not simply to keep things clean. It is a critical operational discipline that directly protects the purity of your final product and the long-term viability of your investment.

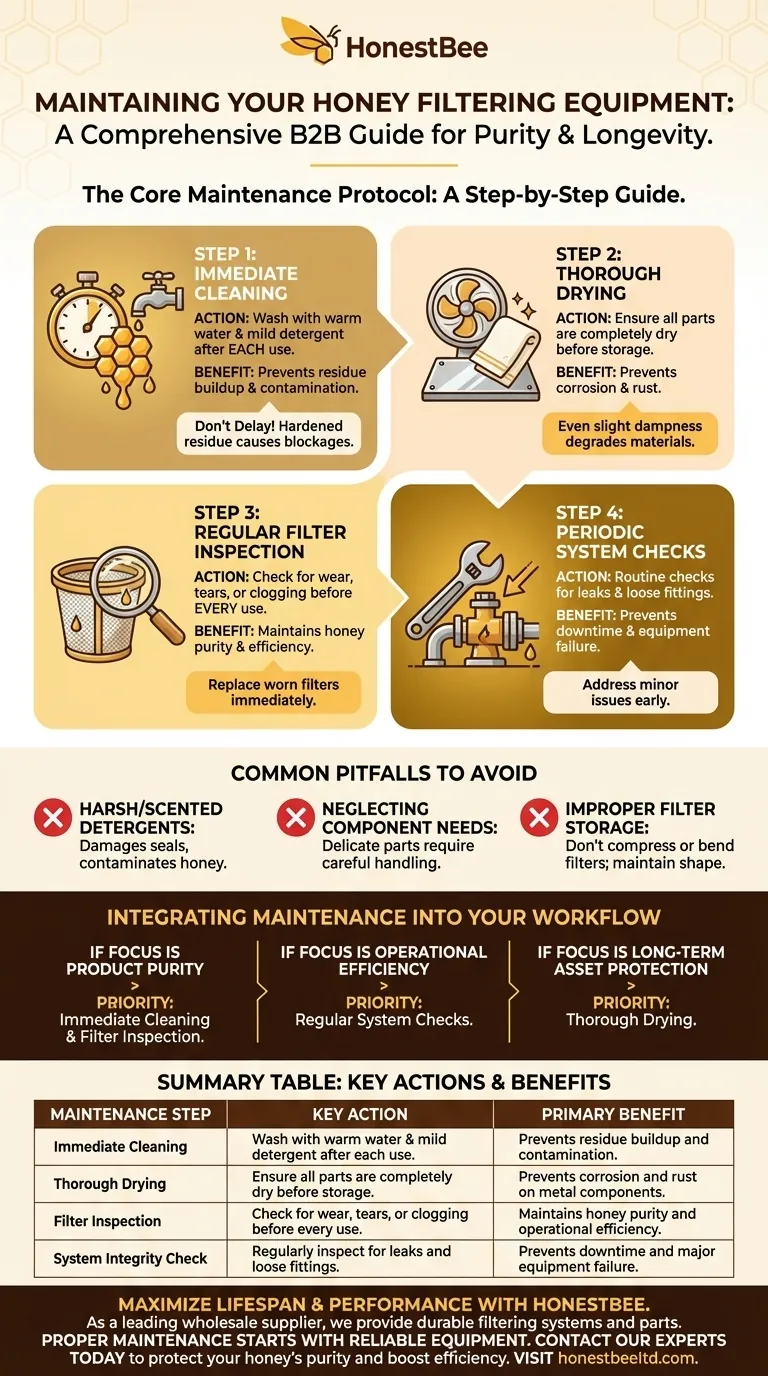

The Core Maintenance Protocol: A Step-by-Step Guide

A consistent maintenance schedule is the most effective way to ensure both equipment longevity and product quality. Each step serves a distinct and vital purpose.

Step 1: Immediate Cleaning After Each Use

After every processing run, all components must be washed. Use warm water and a mild detergent to effectively dissolve and remove honey residue, wax, and other impurities.

Delaying this step allows residue to harden, making it significantly more difficult to clean and potentially causing blockages in filters and pumps.

Step 2: Thorough Drying to Prevent Corrosion

Once cleaned, every part of the equipment must be dried completely. This is the single most important action for preventing rust and corrosion on metal components.

Storing equipment while even slightly damp can degrade materials over time, leading to premature failure and potential contamination of the honey.

Step 3: Regular Filter Inspection and Replacement

Filters and strainers are the heart of the system and require constant attention. Before each use, inspect them for signs of wear, tears, or clogging.

A compromised filter reduces operational efficiency and fails at its primary job: removing impurities. Worn-out filters must be replaced immediately to maintain honey quality.

Step 4: Periodic System Integrity Checks

Incorporate a routine check for any leaks or loose fittings into your schedule. This is especially critical for systems that include pumps or pressurized components.

Addressing these minor issues proactively prevents inefficient operation, potential product loss, and the risk of more significant equipment failure during a processing run.

Common Pitfalls to Avoid

Executing the protocol correctly is as important as having one. Many well-intentioned operators make simple mistakes that undermine their efforts.

Using Harsh or Scented Detergents

Never use harsh chemicals or scented soaps for cleaning. These substances can damage seals and sensitive components, and their residues can easily contaminate the honey, altering its taste and purity.

Neglecting Component-Specific Needs

Different parts have different needs. While a stainless steel tank is robust, pumps and bottling machines may have delicate seals or electronic parts that require more careful handling during cleaning and drying.

Storing Filters Improperly

Do not store filters compressed or bent. After cleaning and drying, store them in a way that maintains their shape to prevent damage that could compromise their effectiveness.

Integrating Maintenance into Your Workflow

Adopting this protocol is about making it a non-negotiable part of your operational rhythm. Your specific focus will determine which steps you emphasize.

- If your primary focus is product purity: Your highest priorities are immediate cleaning after every use and diligent filter inspection to prevent any contamination.

- If your primary focus is operational efficiency: Emphasize regular system checks for leaks and loose fittings to prevent unexpected downtime during processing.

- If your primary focus is long-term asset protection: The most critical step is ensuring every component is meticulously dried to prevent corrosion and extend equipment lifespan.

Ultimately, consistent and thorough maintenance is the cornerstone of any successful honey processing operation.

Summary Table:

| Maintenance Step | Key Action | Primary Benefit |

|---|---|---|

| Immediate Cleaning | Wash with warm water & mild detergent after each use. | Prevents residue buildup and contamination. |

| Thorough Drying | Ensure all parts are completely dry before storage. | Prevents corrosion and rust on metal components. |

| Filter Inspection | Check for wear, tears, or clogging before every use. | Maintains honey purity and operational efficiency. |

| System Integrity Check | Regularly inspect for leaks and loose fittings. | Prevents downtime and major equipment failure. |

Maximize the lifespan and performance of your honey processing equipment with HONESTBEE.

As a leading wholesale supplier to commercial apiaries and distributors, we provide the durable, high-quality filtering systems and replacement parts your operation depends on. Proper maintenance starts with reliable equipment.

Contact our experts today to discuss your needs and discover how our solutions can help you protect your honey's purity and boost your operational efficiency.

Visual Guide

Related Products

- Stainless Steel Triangle Support Honey Strainer and Filters

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- Stainless Steel Manual 8 Frame Radial Honey Extractor Machine for Beehives

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- How does filtering honey assist beekeepers in complying with regulations? Meet Global Quality & Purity Standards

- What role does pressure centrifugal filtration equipment play in the honey post-processing stage? Enhance Purity

- How does industrial-grade fine-pore filtration equipment ensure the physical purity of honey? Expert Filtration Guide

- What are the benefits of drying honey filtering equipment after use? Protect Your Honey Quality & Equipment Investment

- How can a honey filtering machine be utilized for filtering raw honey? Maximize Purity and Commercial Value

- How do Industrial Honey Filtration Systems improve operational efficiency? Optimize Your Honey Processing Workflow

- Why is the honey filtering process essential? Elevate Your Harvest to Premium Commercial Standards

- What role does industrial-grade filtration equipment play in the production of raw honey? Enhance Purity and Quality