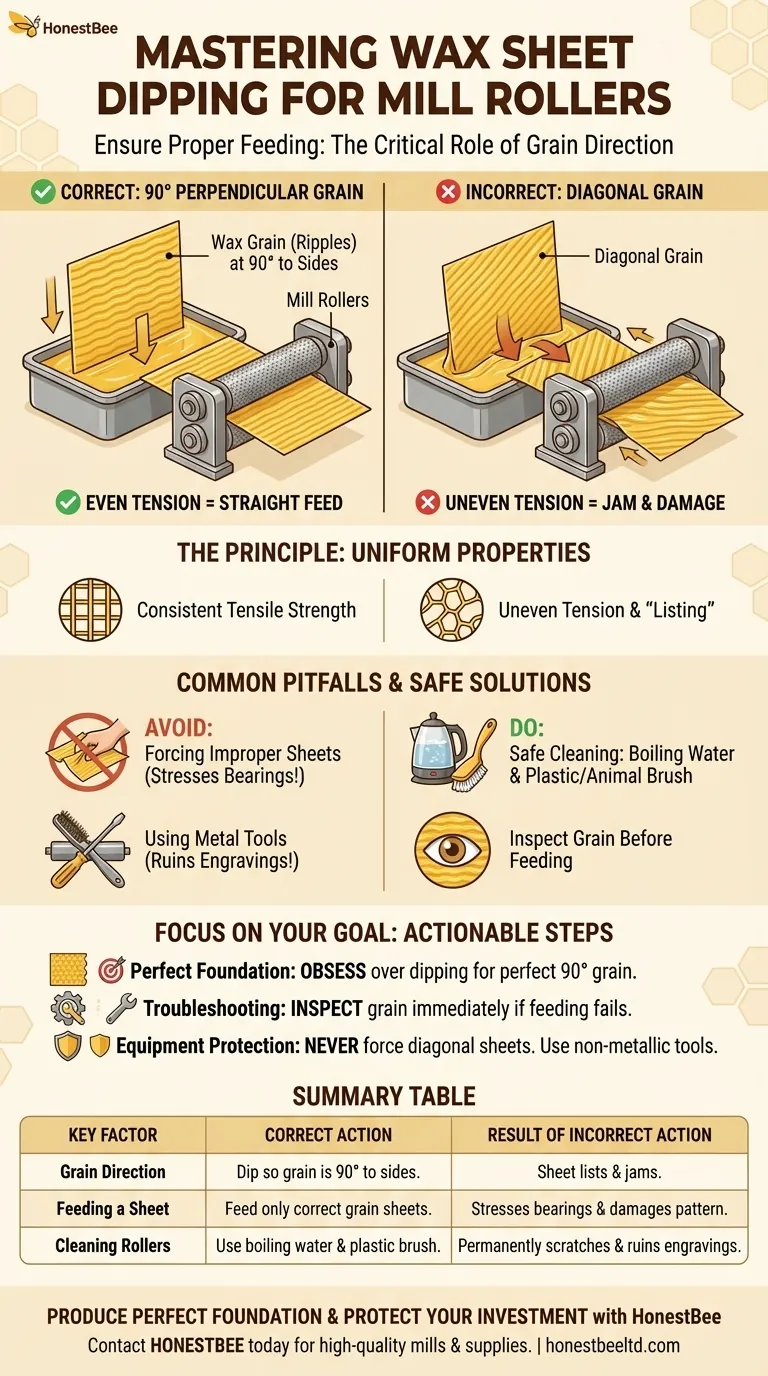

To ensure proper feeding through mill rollers, wax sheets must be dipped so the grain, visible as ripples or waves, runs perfectly perpendicular (90 degrees) to the sides. If this grain runs diagonally, it indicates an incorrect dipping technique, which is the primary cause of sheets failing to feed straight through the rollers.

The orientation of the wax grain is not a minor detail; it is the fundamental factor that determines whether a sheet will feed straight or bind in the mill. A diagonal grain is the most common and preventable cause of foundation milling failures.

The Principle: Why Grain Direction is Critical

The precise geometry of your foundation mill rollers requires a wax sheet with uniform properties across its width. The grain direction dictates the sheet's structural integrity and how it behaves under the pressure of the embossing rollers.

Understanding Wax Grain

The "ripples" or "waves" you see in a finished wax sheet are a visual representation of how the wax flowed and cooled on the dipping board. This grain indicates the direction of the wax's internal structure.

How a 90-Degree Grain Works

When the grain is at a perfect 90-degree angle to the sides, the sheet has consistent tensile strength across its entire width. As the rollers pull the sheet in, they apply even pressure, allowing it to feed straight and true.

The Problem with a Diagonal Grain

A diagonal grain creates uneven tension. One side of the sheet is structurally different from the other. As the rollers grip it, one side will stretch or compress more, causing the sheet to "list" or "walk" sideways, resulting in a jam.

Common Pitfalls to Avoid

Even with a clear understanding of the goal, mistakes can happen. Recognizing these common issues is key to protecting your equipment and producing high-quality foundation.

Forcing an Improper Sheet

It can be tempting to try and manually guide a listing sheet through the mill. This rarely works and puts immense stress on the roller bearings and the delicate engraved pattern.

Wax Buildup on Rollers

When a sheet jams, wax can get stuck and build up on the mill rollers. This buildup will ruin the cell pattern on all subsequent sheets and can make future jams more likely.

Safe Roller Cleaning

To remove stuck wax, pour boiling water over the rollers to soften it. Then, gently scrub the wax off using only a plastic or animal bristle brush.

Never use a wire brush, screwdriver, or any metal tool. The rollers are typically made of a soft metal, and a metal tool will permanently scratch and damage the hexagonal cell engravings.

Making the Right Choice for Your Goal

Achieving a perfect wax sheet is a matter of focusing on the correct details. Your approach should be guided by your primary objective.

- If your primary focus is producing perfect foundation: Obsess over the dipping process to ensure the wax grain is always at a 90-degree angle to the sheet's edge.

- If your primary focus is troubleshooting feeding issues: Immediately inspect the grain of your wax sheets; a diagonal pattern is the most likely culprit for any sheet that won't feed straight.

- If your primary focus is protecting your equipment: Never force a diagonally-grained sheet through the mill and always use non-metallic tools for cleaning built-up wax.

Mastering a consistent, straight dipping technique is the essential skill for creating flawless beeswax foundation.

Summary Table:

| Key Factor | Correct Action | Result of Incorrect Action |

|---|---|---|

| Grain Direction | Dip sheet so grain runs perpendicular (90°) to sides. | Sheet lists sideways, causing a jam in the mill. |

| Feeding a Sheet | Feed only sheets with correct grain. | Forcing a sheet stresses roller bearings and damages the pattern. |

| Cleaning Rollers | Use boiling water and a plastic/animal bristle brush. | Using metal tools permanently scratches and ruins the cell engravings. |

Produce Perfect Foundation and Protect Your Investment

Consistently creating wax sheets that feed smoothly is essential for efficient foundation production. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, durable foundation mills and supplies needed for reliable, high-volume operations.

Stop dealing with frustrating jams and damaged equipment. Let our experts provide you with the right tools and knowledge for success.

Contact HONESTBEE today to discuss your wholesale needs and ensure your milling process is flawless.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

People Also Ask

- What happens during the feeding stage of the beeswax flatting and embossing process? Ensure Perfect Foundation Sheets

- What is the function of a beeswax foundation machine? Boost Hive Efficiency and Honey Production

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation

- What are the key features of the beeswax foundation machine's mold surface? Non-Stick, Durable & Precise

- How do fully automatic wax foundation machines benefit beekeepers? Boost Efficiency & Scale Your Apiary