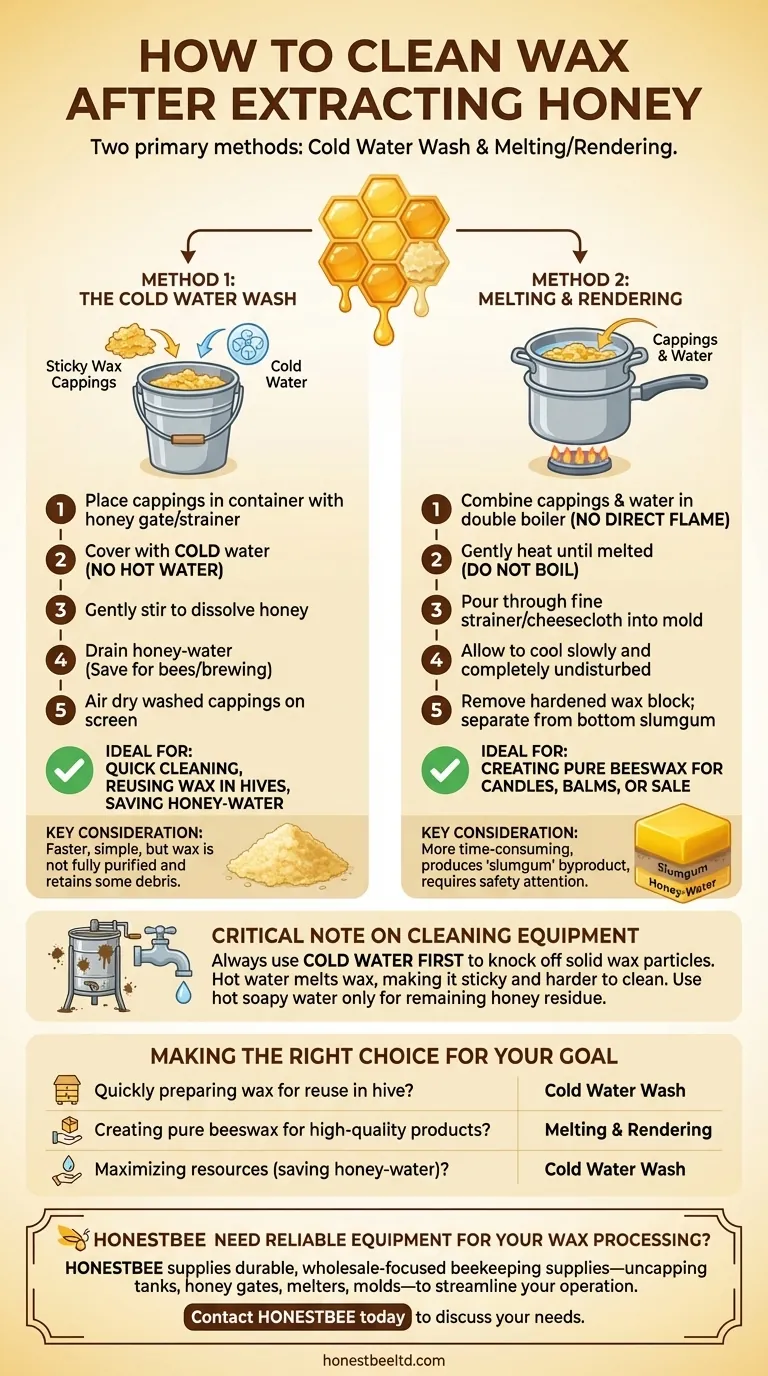

To clean wax after honey extraction, the two primary methods are a cold water wash and a melting (or rendering) process. A cold water wash uses cold water to dissolve the residual honey without melting the wax, which is a quick method for basic cleaning. For a more thorough cleaning that produces pure beeswax, you must melt the cappings with water, which allows the pure wax to separate from the heavier honey and debris as it cools.

The core principle of cleaning beeswax is separation. You are simply using differences in temperature and density to separate three components: the valuable wax, the residual honey, and any hive debris.

The Goal: From Sticky Cappings to Pure Beeswax

What Are Wax Cappings?

Wax cappings are the fresh beeswax seals that bees build over cells of cured honey. When you uncap frames to extract honey, you collect these cappings, which are saturated with honey.

The Objective: Isolate the Wax

Your goal is to separate this sticky mixture into its core components. This leaves you with clean, pure beeswax that can be stored in blocks and used for a variety of purposes.

Method 1: The Cold Water Wash

This method is ideal for quickly removing most of the honey while leaving the wax in its raw state.

The Principle Behind It

Cold water readily dissolves honey but will not melt beeswax. This allows you to wash the honey away, leaving behind cleaner wax particles.

Step-by-Step Process

- Place your sticky wax cappings into a bucket or large container with a honey gate or strainer at the bottom.

- Cover the cappings with cold water. Using hot water at this stage will melt the wax and create a much larger mess.

- Gently stir and agitate the mixture to help dissolve the honey into the water.

- Drain the honey-water mixture. This sweet water can be saved to feed back to your bees or for use in brewing.

- Allow the washed cappings to air dry completely on a screen or tray.

Method 2: Melting and Rendering

This process uses heat and water to produce a pure, clean block of beeswax, but it is more involved.

The Principle Behind It

When melted together, wax, honey, and water will separate into layers based on density. The less-dense wax will float to the top, while the heavier water, honey, and debris (often called slumgum) will sink to the bottom.

Step-by-Step Process

- Combine your wax cappings and water in a dedicated pot or a double boiler. Never heat beeswax over a direct flame, as it is flammable.

- Gently heat the mixture until all the wax has completely melted. Do not let it boil.

- Carefully pour the hot liquid through a fine strainer or multiple layers of cheesecloth into a mold (a plastic bucket or bread pan works well).

- Allow the container to cool slowly and completely without being disturbed. This can take many hours.

- Once fully hardened, you can remove the block of wax. The clean beeswax will be the top layer, which can be easily separated from the layer of slumgum and honey-water at the bottom.

Understanding the Trade-offs

Cold Water Wash

This method is fast, simple, and requires no special equipment. It effectively saves the diluted honey for other uses. However, the resulting wax is not fully purified and will still contain small amounts of debris.

Melting and Rendering

This process produces a much cleaner, purer beeswax suitable for high-quality products like candles or cosmetics. The downside is that it is more time-consuming, requires careful attention to safety, and results in a "slumgum" byproduct that must be discarded.

A Critical Note on Cleaning Equipment

Always use cold water first when cleaning an extractor or tools with wax on them. A strong jet of cold water will physically knock off solid wax particles. Using hot water immediately will melt the wax, smearing it into a thin, sticky film that is much harder to clean. After the wax is gone, you can use hot, soapy water to remove the remaining honey residue.

Making the Right Choice for Your Goal

- If your primary focus is quickly preparing wax for reuse in the hive: The cold water wash is the most efficient method for this purpose.

- If your primary focus is creating pure beeswax for candles, balms, or to sell: You must use the melting and rendering method to achieve the necessary purity.

- If your primary focus is maximizing your resources: Use the cold water wash and save the sweet water byproduct to feed your bees.

By choosing the right technique, you can effectively transform a sticky byproduct of extraction into a valuable and reusable resource.

Summary Table:

| Method | Best For | Result | Key Consideration |

|---|---|---|---|

| Cold Water Wash | Quick cleaning, reusing wax in hives, saving honey-water for bees | Cleaner, but not pure, wax | Fast and simple; wax retains some debris |

| Melting & Rendering | Creating pure beeswax for candles, balms, or sale | Pure, clean beeswax block | More time-consuming; produces slumgum byproduct |

Need Reliable Equipment for Your Wax Processing?

Whether you're a commercial apiary scaling up your honey extraction or a distributor supplying beekeepers, having the right tools makes all the difference. HONESTBEE supplies durable, wholesale-focused beekeeping supplies and equipment—from uncapping tanks and honey gates to melters and molds—to streamline your entire operation.

Contact HONESTBEE today to discuss your needs and discover how our equipment can help you efficiently transform wax cappings into a valuable resource.

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Professional Thermostatic Conical Honey Melter

People Also Ask

- What are the advantages of using a mechanical honey press? Maximize Yield and Hygiene in Your Apiary

- What was the overall experience with the honey press? Maximize Yield for Small-Scale Beekeeping

- How can the wax cake from honey pressing be processed? Top Methods to Separate Residual Honey and Debris

- What makes the Honey Press a valuable tool for honey enthusiasts and beekeepers? Unlock Superior Honey Quality and Yield

- How long does it take for beeswax to separate from honey? A Guide to Efficient Harvesting

- What happens to the wax after pressing in a honey press? A Guide to Maximizing Your Hive's Yield

- What are the benefits of pressing honeycomb for honey harvesting? Maximize Bioactivity and Artisanal Quality

- What are the reasons for choosing a honey press over a honey extractor? Key Benefits for Hive Health & Efficiency