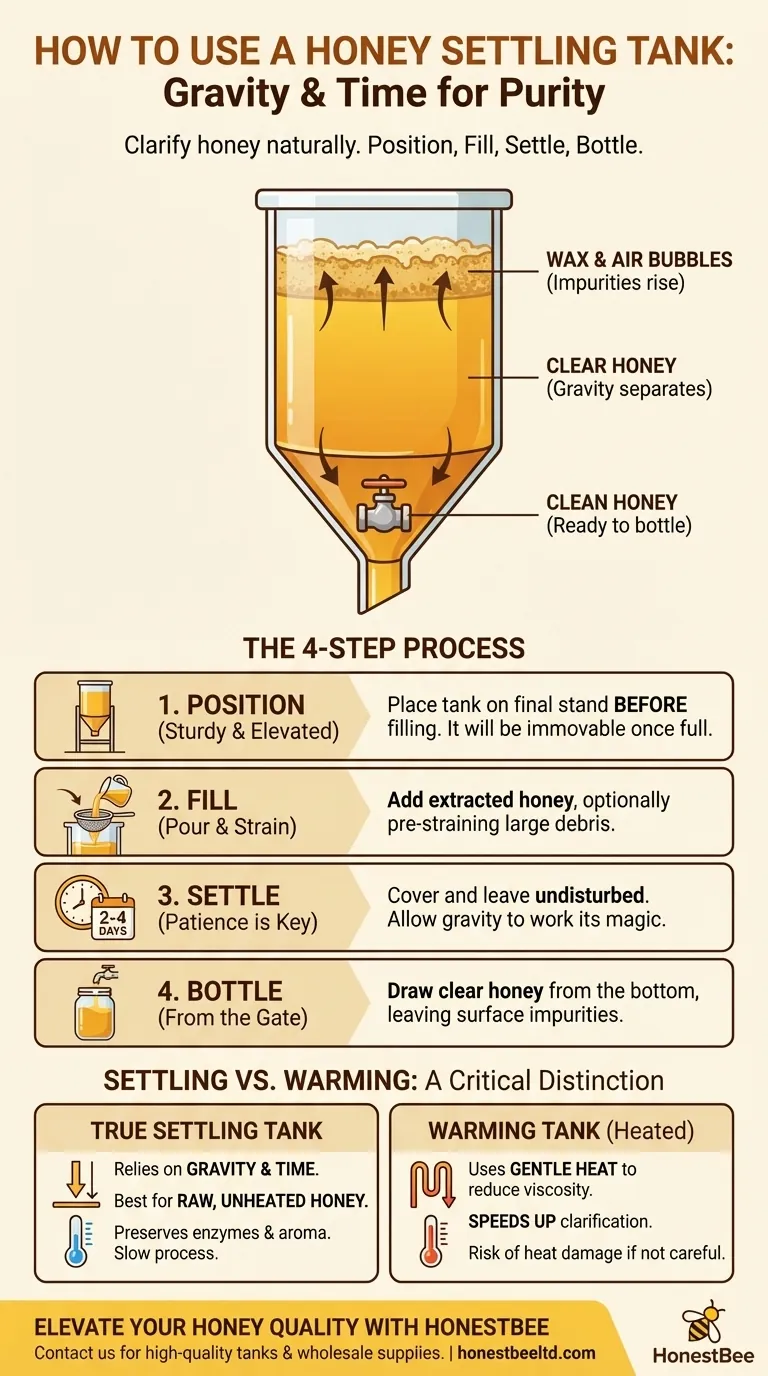

To use a honey settling tank, first position it in its final, elevated location, as it will be immovable once full. Fill the tank with your extracted honey, cover it, and allow it to sit undisturbed for several days. This process uses gravity to naturally clarify the honey, allowing air bubbles, wax, and other fine particles to rise to the surface, leaving you with cleaner honey to bottle from the gate at the bottom.

The core purpose of a settling tank is to clarify honey through patience and gravity. While often confused with warming tanks, which use heat to reduce viscosity for faster processing, a true settling tank focuses on letting impurities separate naturally over time.

The Principle: Clarification Through Gravity

A settling tank is a simple but powerful tool for improving the quality and appearance of your final product. It works on the basic principle that most impurities in honey are less dense than the honey itself.

What "Settling" Achieves

When left undisturbed, tiny air bubbles introduced during extraction, fine wax particles, and other debris slowly float to the top. This forms a layer on the surface that can be skimmed off later, leaving the bulk of the honey below clear and brilliant.

The Importance of Positioning

Your first step is the most critical. Place the tank on a sturdy table or stand before you add any honey. A full tank can weigh hundreds of kilograms and will be impossible to lift safely. The elevation is necessary to allow you to easily place jars or buckets under the honey gate for bottling.

The Filling Process

Pour or pump your freshly extracted honey directly into the top of the settling tank. It's often helpful to first run the honey through a coarse strainer to remove large pieces of wax or debris before it enters the tank.

Patience is Key: The Settling Period

Cover the tank to keep out dust and debris, and simply wait. The ideal settling time is typically 2-4 days, but this depends heavily on the temperature of the room. Warmer honey is less viscous and will clarify much faster than cold honey.

Bottling Clear Honey

Once the honey has settled, you can begin bottling directly from the honey gate at the bottom of the tank. The clean, clarified honey will flow out, leaving the layer of foam and wax particles undisturbed at the top. Be sure to close the gate before the level drops low enough to pull in the surface layer.

Settling vs. Warming: A Critical Distinction

While both tools are used in honey processing, their primary functions are different. Understanding this distinction is key to managing your honey correctly.

The Role of a True Settling Tank

A standard settling tank relies solely on gravity and time. It is the preferred method for beekeepers who want to produce raw, unheated honey, as it preserves the natural enzymes and delicate aromas.

The Role of a Warming Tank

A warming tank, or heated clarifier, uses a low-wattage heating element to gently warm the honey. The primary goal is to reduce viscosity (make it thinner), which allows it to be filtered and bottled much more quickly. A key side effect of gentle heat is that it also dramatically speeds up the settling process.

Understanding the Trade-offs

Choosing your method involves balancing purity, speed, and effort. There is no single "best" approach for everyone.

The Downside of Patience

Natural settling is slow. For a commercial operation, having honey sit for several days can create a significant bottleneck in the production workflow, tying up equipment and space.

The Risk of Applied Heat

Heating honey must be done with extreme care. Overheating can darken the honey, alter its flavor, and destroy the beneficial enzymes that many customers seek. A dedicated, thermostatically controlled warming tank is essential to avoid this damage.

The Challenge of a Full Tank

As stated, once a tank is full, it is effectively a permanent fixture until it is empty. Always plan your workflow and the tank's location before you begin filling it.

Making the Right Choice for Your Goal

Your ideal process depends entirely on your operational scale and your philosophy as a beekeeper.

- If your primary focus is producing raw, unheated honey: Rely exclusively on a standard settling tank in a warm room and allow ample time for gravity to do its work.

- If your primary focus is speed and processing efficiency: A thermostatically controlled warming tank is the superior tool, as it accelerates clarification and makes bottling significantly faster.

- If you are a small-scale hobbyist: A simple food-grade bucket can serve as a small settling tank, allowing you to clarify a few gallons at a time without investing in specialized equipment.

Ultimately, taking the time to properly settle your honey is a crucial step that elevates your final product from simply extracted to beautifully finished.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Position | Place tank on a sturdy, elevated stand | Ensures easy bottling; tank is immovable when full |

| 2. Fill | Add extracted honey, optionally pre-straining | Removes large debris before the settling process begins |

| 3. Settle | Cover and leave undisturbed for 2-4 days | Allows air bubbles and wax particles to rise to the surface |

| 4. Bottle | Draw clarified honey from the bottom gate | Leaves impurities behind, yielding a clean, brilliant product |

Ready to elevate your honey's quality and streamline your operation?

For commercial apiaries and beekeeping equipment distributors, the right equipment is key to efficiency and product excellence. HONESTBEE supplies high-quality, durable honey settling tanks and a full range of beekeeping supplies designed for wholesale-focused operations.

Let us help you build a more efficient honey processing workflow. Contact our experts today to discuss your specific needs and discover how our equipment can benefit your business.

Visual Guide

Related Products

- Stainless Steel Honey Storage and Settling Tank with Double Strainer

- Professional Honey Storage Tank with Agitation System

- Stainless Steel Heated Honey Tank Warming Heating Tank

- Stainless Steel Uncapping Tank with Stand and Strainer

- Stainless Steel Honey Storage Tank with Lid for Honey

People Also Ask

- What is the role of specialized settling containers with side nozzles? Optimize Your Honey Primary Filtration

- Can I store honey in stainless steel? A Guide to Safe, Long-Term Honey Storage

- What are the functions of settling tanks and bulk storage tanks in beekeeping? Achieve Commercial-Grade Honey Clarity

- What is the purpose of a settling tank or de-aerator in honey clarification? Achieve Professional Liquid Clarity

- How do food-grade honey storage tanks and filling equipment contribute to the commercialization of bee products?