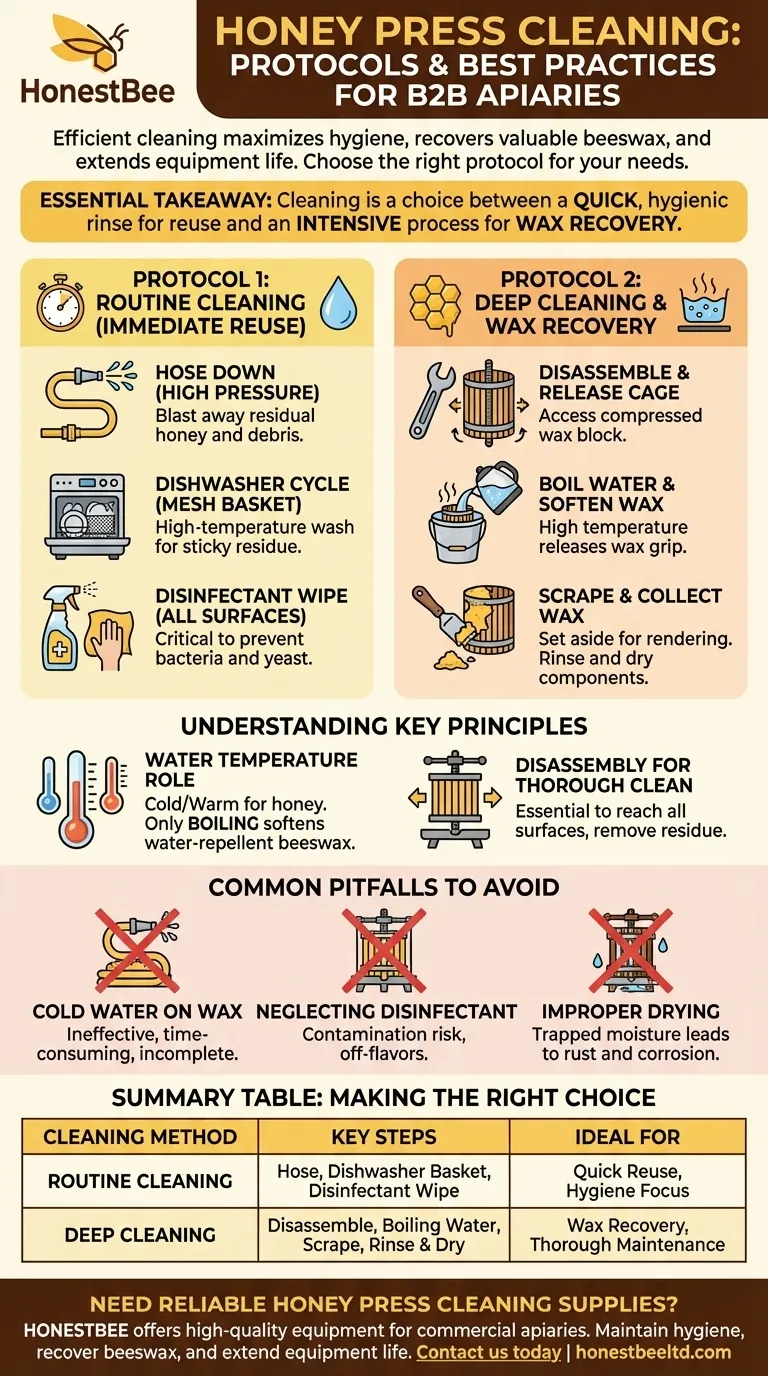

To clean a honey press after use, the process involves two distinct methods depending on the goal. For a routine clean, the press is hosed down aggressively, the mesh basket is often cleaned in a dishwasher, and the unit is wiped with a disinfectant. For a deep clean that includes recovering valuable beeswax, the process involves disassembling the press cage and using boiling water to soften and scrape away the wax before final rinsing and drying.

The essential takeaway is that cleaning a honey press isn't a single procedure, but a choice between a quick, hygienic rinse for immediate reuse and a more intensive process designed to recover valuable beeswax.

The Two Primary Cleaning Protocols

Understanding which cleaning method to use depends on whether you are simply finishing a pressing or intentionally harvesting wax as a secondary product.

Protocol 1: Routine Cleaning for Immediate Reuse

This method is fast and focuses on removing residual honey and debris to prepare the press for its next use or for storage.

First, take the press outside. Use a hose on a high-pressure or "jet" setting to blast away the most obvious remnants of honey and wax from all surfaces.

For a more thorough clean, removable parts like the mesh basket can be put through a dishwasher cycle. This ensures a high-temperature wash that removes any sticky residue.

Finally, wipe down the entire press, especially parts that cannot go in a dishwasher, with a suitable natural disinfectant. This step is critical for preventing bacteria or yeast growth.

Protocol 2: Deep Cleaning and Wax Recovery

This more involved process is used when you want to harvest the block of compressed wax left after pressing.

Begin by unwinding the press and releasing the steel cage that contains the compressed wax.

Place the cage into a large bucket and pour boiling water over it. The high temperature will quickly soften the wax, causing it to release its grip on the metal cage.

Use a suitable tool to scrape the softened wax from the cage. The collected wax can then be set aside for later rendering and filtering. After the bulk is removed, you can add cold water, which will cause the remaining wax to solidify for easy collection.

After all wax is recovered, rinse the components, dry them thoroughly, and reassemble the press for storage.

Understanding Key Principles

Beyond the steps themselves, understanding the principles behind them ensures you can adapt the process to your specific equipment and needs.

The Critical Role of Water Temperature

The choice of water temperature is deliberate. Cold or warm water from a hose is sufficient for dissolving and washing away honey.

However, beeswax has a higher melting point and is water-repellent. Only boiling water is effective at softening it enough to be scraped away easily from the press components.

Disassembly for a Thorough Clean

Both protocols rely on a key practice: separating the components. Whether it's removing the mesh basket for the dishwasher or taking out the entire steel cage, disassembly is essential for reaching all surfaces and ensuring no residue is left behind.

Common Pitfalls to Avoid

Proper cleaning preserves your equipment and ensures the quality of your honey. Avoiding these common mistakes is crucial for long-term success.

Using Only Cold Water on Wax

Attempting to remove a significant amount of compressed wax with only a cold-water hose is ineffective. This will not soften the wax and will result in a difficult, time-consuming, and incomplete cleaning.

Neglecting a Final Disinfectant Wipe

Simply hosing the press down may leave behind microscopic yeast and bacteria. Over time, this can contaminate future batches of honey, potentially leading to fermentation or off-flavors. A final wipe-down is a non-negotiable step for food safety.

Improper Drying Before Storage

After any water-based cleaning, all parts of the press must be dried completely before reassembly and storage. Trapped moisture, especially in the screw mechanism or between metal plates, can lead to rust and corrosion, damaging the equipment over time.

Making the Right Choice for Your Goal

Your cleaning approach should be dictated by your immediate needs and long-term goals for your apiary products.

- If your primary focus is a quick turnaround: Use the hose, dishwasher, and disinfectant method for the most efficient cleaning between batches.

- If your primary focus is maximizing your harvest: Employ the boiling water and scraping method to recover every bit of valuable beeswax from the pressings.

- If your primary focus is long-term equipment care: Always ensure the press is completely dry before reassembly to prevent rust and corrosion.

A properly cleaned and maintained press is an essential tool for every successful honey harvest.

Summary Table:

| Cleaning Method | Key Steps | Ideal For |

|---|---|---|

| Routine Cleaning | Hose down, dishwasher mesh basket, disinfectant wipe | Quick reuse, hygiene focus |

| Deep Cleaning | Disassemble, boiling water, scrape wax, rinse and dry | Wax recovery, thorough maintenance |

Need reliable honey press cleaning supplies for your apiary? HONESTBEE supplies high-quality beekeeping equipment and tools to commercial apiaries and distributors through wholesale operations. Our products help you maintain hygiene, recover valuable beeswax, and extend equipment life. Contact us today to enhance your beekeeping efficiency and maximize your harvest!

Visual Guide

Related Products

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Stainless Steel Honey Press Wax Press with Tank

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- Why are honey presses indispensable for larger beekeeping operations? Scale Your Harvest with High-Volume Processing

- What are the benefits of pressing comb for bees' health? Incentivize Proactive Hive Renewal

- What is the primary function of a mechanical honey press? Maximize Your Extraction Yield and Efficiency

- Can the Honey Press be used for purposes other than honey extraction? Unlock Its Versatility for Juicing & Herbal Projects

- What equipment is needed to perform the crush and strain method of honey extraction? Start Harvesting for Less

- What is the crush and strain method for extracting honey? A Simple Guide to Low-Cost Honey Harvesting

- How to clean wax after extracting honey? Master the Cold Wash vs. Melting Methods

- What is the purpose of variable pressure control in a honey press? Mastering Quality and Yield