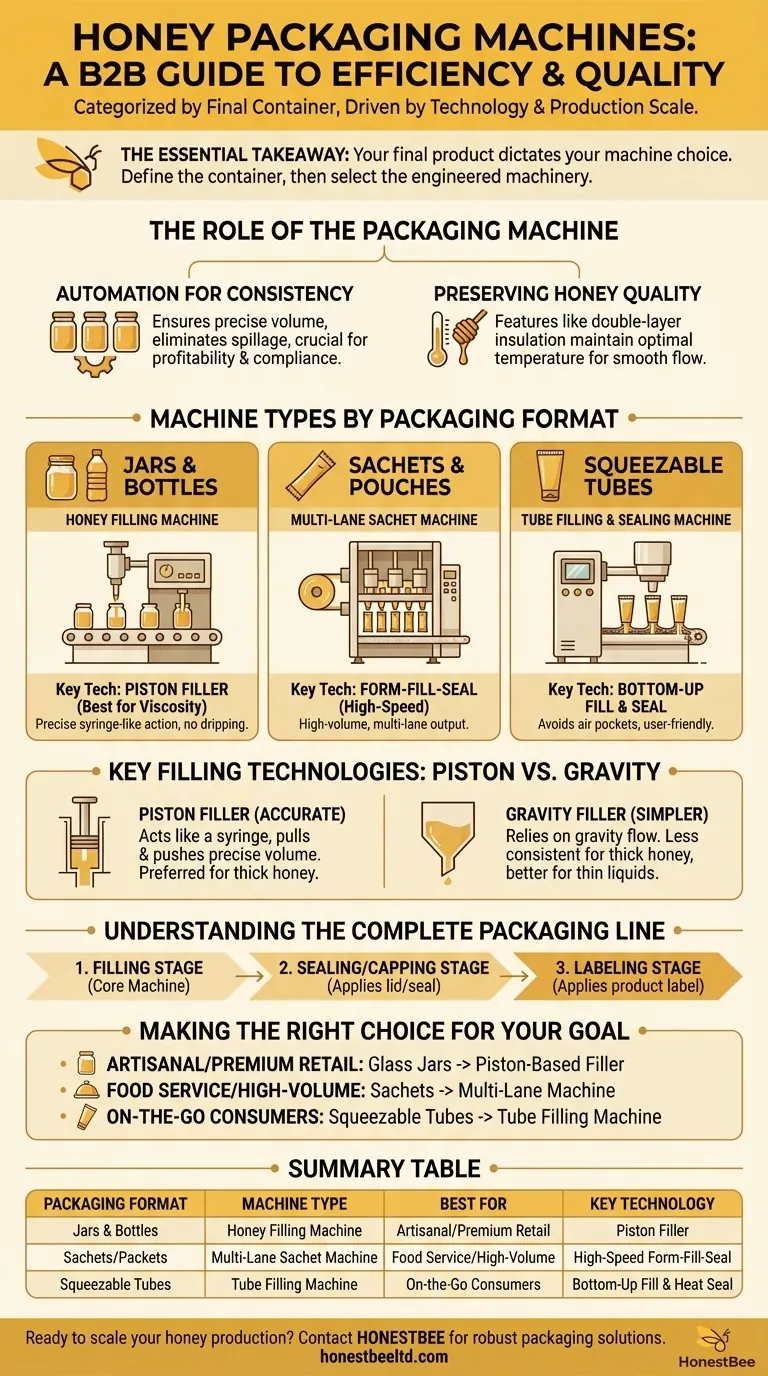

The most common types of honey packaging machines are categorized by the final container they are designed to fill. These include honey filling machines for jars and bottles, multi-lane sachet machines for single-serving packets, and tube filling machines for squeezable tubes. The specific technology used, such as a piston or gravity filler, is a critical secondary distinction based on the viscosity of the honey and the required accuracy.

The essential takeaway is that your choice of a honey packaging machine is dictated entirely by your desired final product. You must first decide on the container—be it a glass jar, a plastic squeeze bottle, or a single-use sachet—and then select the machinery engineered to handle that specific format and your production scale.

The Role of the Packaging Machine

A dedicated packaging machine automates what is otherwise a slow, inconsistent, and labor-intensive process. Its primary job is to dispense a precise amount of honey into a container cleanly and efficiently.

Automation for Consistency

Manual filling is prone to variations in volume and spillage. An automated machine ensures every single jar, bottle, or sachet contains the exact same amount of product, which is crucial for profitability and regulatory compliance.

Preserving Honey Quality

Honey's viscosity changes dramatically with temperature. Professional machines often incorporate features like double-layer insulated barrels or gentle heating systems. This maintains the honey at an optimal, consistent temperature, ensuring it flows smoothly without being damaged.

Machine Types by Packaging Format

The type of container you plan to sell is the single most important factor in determining the right machine.

For Jars and Bottles

This is the most traditional format, requiring a honey filling machine. These machines use a conveying system to move glass or plastic containers into position.

A nozzle then dispenses the honey, often using a piston filler for thick, viscous honey to ensure a precise volume is pushed into the container. A precise shut-off valve or a "suck-back" device prevents dripping after the fill is complete.

For Sachets and Pouches

For single-serving portions, like those for restaurants or travel, a multi-lane sachet packing machine is used. This is a high-speed system that forms, fills, and seals small packets from a continuous roll of film.

These machines are built for high-volume output, with "multi-lane" meaning they can fill several sachets simultaneously.

For Squeezable Tubes

Portable, on-the-go honey products are often packaged in plastic tubes. A tube filling and sealing machine is designed specifically for this purpose.

It holds the tube, fills it from the bottom up to avoid air pockets, and then uses heat or ultrasonic technology to crimp and seal the end.

Key Filling Technologies: Piston vs. Gravity

Within the category of jar and bottle fillers, the mechanism used to move the honey is a critical detail.

Piston Fillers

A piston filler acts like a large syringe. A piston pulls back to draw a precise volume of honey into a cylinder and then pushes it out through the nozzle into the container.

This method is extremely accurate and is the preferred choice for thick, viscous liquids like honey, as it provides the force needed for a consistent flow.

Gravity Fillers

A gravity filler holds the honey in a hopper above the containers and relies on gravity to fill them. A valve opens for a set period of time to allow the honey to flow.

While simpler and often less expensive, this method is less suitable for thick honey as the flow rate can be inconsistent. It is better suited for very thin, free-flowing liquids.

Understanding the Complete Packaging Line

It's important to recognize that filling is just one step. A complete automated packaging process involves a series of integrated machines.

The Filling Stage

This is the core machine discussed above, responsible for dispensing the product.

The Sealing/Capping Stage

After filling, a capping machine automatically applies and tightens the lid on a jar or bottle. For sachets, the filling machine performs the heat seal as part of its cycle.

The Labeling Stage

Finally, a labeling machine applies the product label to the container. This ensures a consistent, professional appearance for every unit.

Making the Right Choice for Your Goal

Selecting the correct machinery starts with clarity on your business objectives and the market you serve.

- If your primary focus is artisanal or premium retail: You will almost certainly be using glass jars or bottles, requiring a piston-based honey filling machine.

- If your primary focus is food service or high-volume distribution: A multi-lane sachet packing machine is the most efficient solution for producing single-serving packets.

- If your primary focus is convenience or on-the-go consumer products: A tube filling and sealing machine will create the user-friendly format you need.

Ultimately, aligning your packaging machinery with your product's final form is the foundation of an efficient and scalable operation.

Summary Table:

| Packaging Format | Machine Type | Best For | Key Technology |

|---|---|---|---|

| Jars & Bottles | Honey Filling Machine | Artisanal/Premium Retail | Piston Filler (for accuracy) |

| Sachets/Packets | Multi-Lane Sachet Machine | Food Service/High-Volume | High-Speed Form-Fill-Seal |

| Squeezable Tubes | Tube Filling Machine | On-the-Go Consumers | Bottom-Up Fill & Heat Seal |

Ready to scale your honey production with the right packaging equipment?

At HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with robust, reliable packaging machinery. Whether you need a precision piston filler for premium jars or a high-speed sachet machine for bulk portions, our wholesale-focused operations ensure you get industry-leading equipment to boost your efficiency and protect your product quality.

Contact our experts today for a personalized consultation on the best packaging solution for your specific needs and production goals.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

People Also Ask

- How do automated honey-filling and hive-making machines support Varroa mite control in commercial apiaries?

- What role does honey packaging and filling equipment play in tropical environments? Protect Quality & Prevent Spoilage

- What is the process of stick pack packaging for honey? A Guide to Efficient Single-Serve Production

- What is the best way to bottle honey? Preserve Quality and Maximize Your Harvest

- Why must honey filling machinery use 316L stainless steel? Ensure Food Safety and Prevent Corrosion

- Which specific production challenges are addressed by high-precision honey filling machines? Solve Your Scaling Issues

- What is the significance of high-precision honey filling machines? Secure Quality for Medicinal Bee Products

- Why is high-precision honey-filling and packaging machinery necessary? Protect Bioactivity & Honey Quality