Properly drying your honey filtering equipment after every use is a critical step in professional honey processing. This simple act is not merely about tidiness; it is a fundamental practice that directly prevents equipment corrosion, ensures product hygiene, and protects the integrity of your honey. Failing to do so introduces moisture, which can degrade expensive machinery and compromise the quality of future batches.

While filtering is designed to purify your honey, improper post-use care can ironically reintroduce contaminants. The core issue is trapped moisture, which acts as a catalyst for both metal corrosion and microbial growth, undermining the very purpose of your filtering system.

The Hidden Costs of Trapped Moisture

Many beekeepers focus on the filtering process itself but overlook the importance of what comes after. The cleaning and drying stage is where the quality of your next batch and the lifespan of your equipment are truly decided.

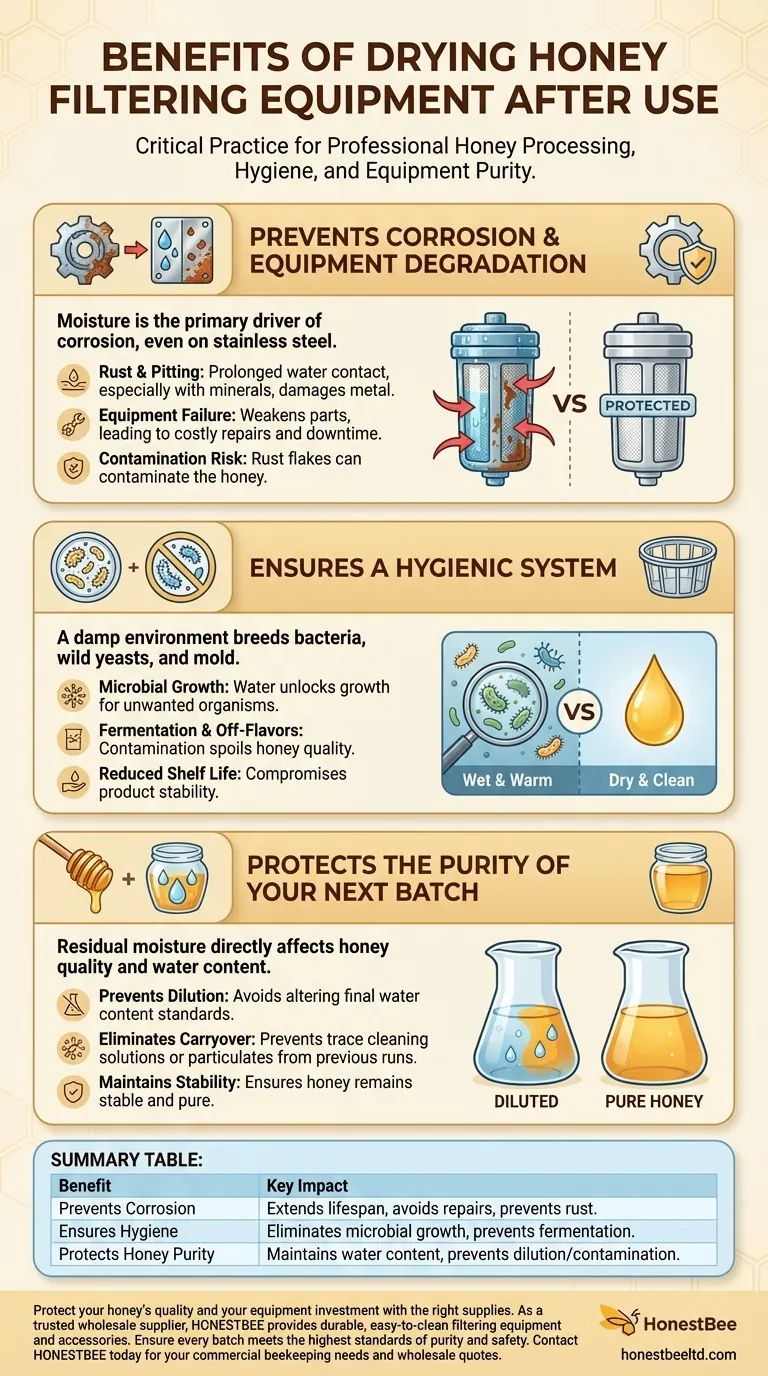

Preventing Corrosion and Equipment Degradation

Moisture is the primary driver of corrosion, even on stainless steel components. While high-grade steel is rust-resistant, prolonged contact with water, especially if it contains minerals or residual cleaning agents, can lead to pitting and rust, particularly at welds and seams.

This degradation is more than cosmetic. Corroded parts can weaken and fail, leading to costly repairs and downtime. More critically, rust flakes can break off and contaminate your honey, creating the very impurities you sought to remove.

Ensuring a Hygienic System

A damp environment is an ideal breeding ground for bacteria, wild yeasts, and mold. Honey's low water content and natural properties make it incredibly stable, but introducing moisture from improperly dried equipment can negate these protections.

When you begin your next filtering run, these microbes can be introduced into the honey. This contamination can lead to fermentation, off-flavors, and a significantly reduced shelf life for your final product. Thorough drying eliminates the habitat these microorganisms need to survive.

Protecting the Purity of Your Next Batch

Beyond microbial risks, leftover water can directly affect your honey's quality. Even a small amount of residual moisture can slightly dilute the honey that first passes through the system.

This can alter the honey's final water content, a critical measure of quality and stability. Furthermore, any remaining water may carry over trace amounts of cleaning solutions or particulates from the previous wash, directly compromising the purity of the new batch.

Common Pitfalls to Avoid

Simply rinsing your equipment is not enough. Understanding the risks associated with "good enough" drying practices is key to maintaining a professional operation.

The "Air-Drying" Trap

Allowing equipment to simply air-dry can be insufficient, especially in humid climates or for complex components like pumps and hoses. Water can remain trapped in crevices, gaskets, and internal mechanisms for days.

This hidden moisture is a primary source of long-term corrosion and contamination. Active drying, using a clean air source or placing components in a warm, dry, and well-ventilated room, is a far more reliable method.

The Myth of "It's Just Water"

It is a common mistake to think a little water won't harm the next batch of honey. This overlooks the fact that water is the key that unlocks two major problems: rust and microbial growth.

Treating proper drying as a non-negotiable step in your sanitation protocol is a form of risk management. The few extra minutes it takes to ensure every component is bone-dry prevents the much larger risks of equipment failure and product spoilage.

Making the Right Choice for Your Goal

Integrating a thorough drying protocol into your post-processing workflow is essential. Your specific motivation will determine where you place your focus.

- If your primary focus is equipment lifespan: Immediately and actively dry all metal components to prevent corrosion and maximize the return on your investment.

- If your primary focus is honey quality and safety: Ensure every surface is completely dry to create a hygienic system that prevents microbial contamination and fermentation.

- If your primary focus is operational efficiency: Having clean, dry, and ready-to-use equipment prevents setup delays and ensures a smooth start for every processing run.

Ultimately, the care you invest in your equipment is a direct investment in the quality and reputation of your honey.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Prevents Corrosion | Extends equipment lifespan, avoids costly repairs and rust contamination. |

| Ensures Hygiene | Eliminates microbial growth (bacteria, mold, yeast) to prevent honey fermentation. |

| Protects Honey Purity | Maintains correct water content and prevents dilution or contamination of the next batch. |

Protect your honey's quality and your equipment investment with the right supplies. As a trusted wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the durable, easy-to-clean filtering equipment and accessories your operation needs. Ensure every batch meets the highest standards of purity and safety.

Contact HONESTBEE today to discuss your commercial beekeeping supply needs and request a wholesale quote.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Two-Stage Plastic Honey Filter for Buckets

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Professional Stainless Steel Honey Filter with Support Handle

People Also Ask

- What is the specific application of precision microfiltration systems in honey? Ensure Accurate Melanoidin Analysis

- Can raw honey be filtered? Unlock the Truth About Processing & Purity

- What is the function of industrial high-mesh screens in stingless bee cerumen pretreatment? Maximize Purity and Yield

- Why is honey pollen filtration equipment regulated? Protect Your Trade Integrity & Traceability

- How do high-precision processing and filtration systems assist in meeting organic honey quality compliance?

- How does high-precision honey filtering equipment maintain organic attributes? Protect Nutrient Density & Clarity

- What types of equipment are used in honey filtering? Build an Efficient System for Pure, Marketable Honey

- How do specialized honey collection materials ensure product quality in stingless bee management? Master Pure Harvesting