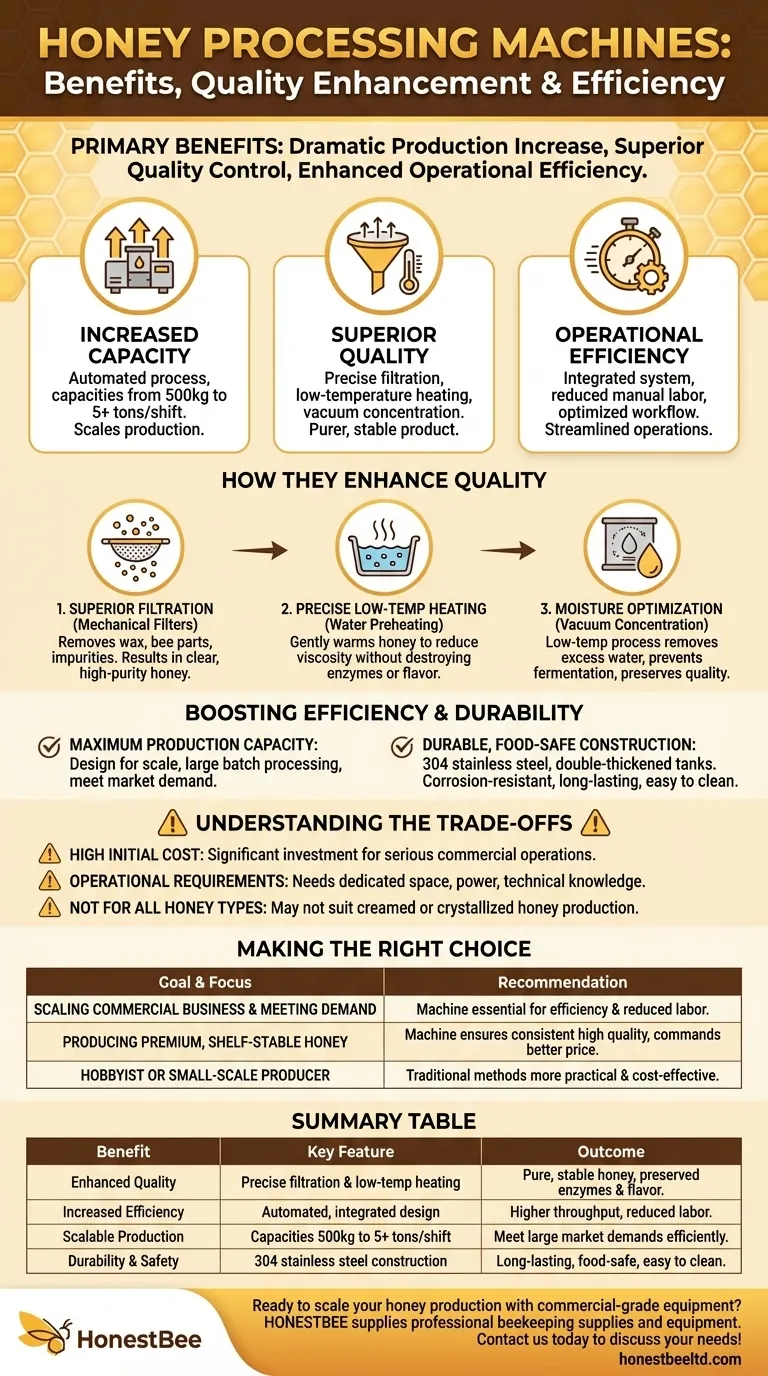

The primary benefits of a honey processing machine are a dramatic increase in production capacity, superior quality control through precise filtration and heating, and enhanced operational efficiency. These machines automate and optimize the process of removing impurities and excess water, resulting in a purer, more stable, and more valuable final product.

A honey processing machine is not just about producing more honey faster. It is a strategic investment in consistency and quality, transforming raw honey into a market-ready product by precisely controlling the factors that degrade it, such as heat, impurities, and moisture content.

How Honey Processing Machines Enhance Quality

The core function of these machines is to refine raw honey without compromising its natural integrity. They achieve this through several carefully controlled mechanisms.

Superior Filtration for Purity

A key feature is the use of mechanical filters to remove physical impurities. This process efficiently sieves out particles like wax, bee parts, and other debris that are naturally present in raw honey.

The result is a visually clear, high-purity product that meets consumer expectations and commercial standards.

Precise Low-Temperature Heating

Honey is sensitive to heat, which can destroy beneficial enzymes and alter its delicate flavor profile. These machines utilize controlled water preheating systems to gently warm the honey.

This slight increase in temperature reduces viscosity, making the honey easier to filter and process without "cooking" it or degrading its quality.

Optimizing Moisture with Vacuum Concentration

Excess water content can lead to fermentation, spoiling the honey and shortening its shelf life. Honey processing machines use a low-temperature vacuum concentration process.

This technique gently removes excess water without high heat, preserving the honey's natural characteristics while ensuring it meets the moisture content standards required for long-term stability.

Boosting Operational Efficiency and Durability

Beyond quality, these machines are built to handle the demands of a commercial operation, providing reliability and high throughput.

Maximizing Production Capacity

These systems are designed for scale, with capacities ranging from 500kg to over 5 tons per shift. This allows producers to process large batches quickly, meeting market demand and improving overall business efficiency.

Durable, Food-Safe Construction

The equipment is typically constructed from 304 stainless steel, often using double-thickened tanks. This material is the industry standard for food processing due to its resistance to corrosion and how easily it can be cleaned and sanitized.

This robust construction ensures a long operational life and prevents any contamination of the honey.

Integrated System Design

Modern machines integrate preheating, filtering, and vacuum concentration into a single, cohesive unit. This streamlined workflow, managed through an electrical control system, reduces manual labor and simplifies the entire production line.

Understanding the Trade-offs

While powerful, these machines represent a significant investment and are not the right solution for every producer.

High Initial Cost

The primary drawback is the substantial capital investment required. This positions them as a tool for serious commercial operations rather than small-scale hobbyists.

Operational Requirements

These are complex pieces of industrial equipment that require dedicated space, adequate power, and a degree of technical knowledge for operation and maintenance.

Not Ideal for All Honey Types

While excellent for liquid honey, these all-in-one systems may not be suitable for producers who specialize in creamed or crystallized honey, which require different processing techniques.

Making the Right Choice for Your Goal

Deciding whether to invest in a honey processing machine depends entirely on the scale and ambition of your operation.

- If your primary focus is scaling a commercial business: The high capacity and automated efficiency are essential for reducing labor costs and meeting large-scale demand.

- If your primary focus is producing premium, shelf-stable honey: The machine's precise control over filtration, temperature, and moisture ensures a consistent, high-quality product that commands a better price.

- If you are a hobbyist or small-scale producer: The cost and complexity are likely unnecessary, and traditional, simpler filtration methods are more practical and cost-effective.

Ultimately, adopting a honey processing machine is a strategic decision that enables producers to elevate both the quality of their product and the capacity of their business.

Summary Table:

| Benefit | Key Feature | Outcome |

|---|---|---|

| Enhanced Quality | Precise filtration & low-temperature heating | Pure, stable honey with preserved enzymes & flavor |

| Increased Efficiency | Automated, integrated system design | Higher throughput, reduced manual labor |

| Scalable Production | Capacities from 500kg to 5+ tons per shift | Meet large market demands efficiently |

| Durability & Safety | 304 stainless steel construction | Long-lasting, food-safe, and easy to clean equipment |

Ready to scale your honey production with commercial-grade equipment?

HONESTBEE supplies professional beekeeping supplies and equipment to commercial apiaries and distributors. Our honey processing machines are designed to help you achieve superior quality control and maximize your operational efficiency.

Contact us today to discuss your needs and discover the right processing solution for your business!

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Professional Thermostatic Conical Honey Melter

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

People Also Ask

- What factors should be considered when choosing between an electric and manual honey extractor?

- How long does it take to extract honey with an extractor? Plan Your Harvest for Maximum Efficiency

- What are the main types of honey extractor machines? A Guide for Beekeepers

- How have centrifuge honey extractors impacted honey harvesting? Boosting Efficiency and Sustainability

- Why is preserving honeycomb integrity important, and how do automated extractors help? Boost Hive Health & Honey Yields