To properly use a bucket opener, you must first position the tool's hook securely under the lid's rim. Apply steady, upward pressure on the handle to pry the lid open, working your way around the circumference in small sections. This method prevents damage to the lid and bucket, ensures your safety, and is far more effective than using improvised tools.

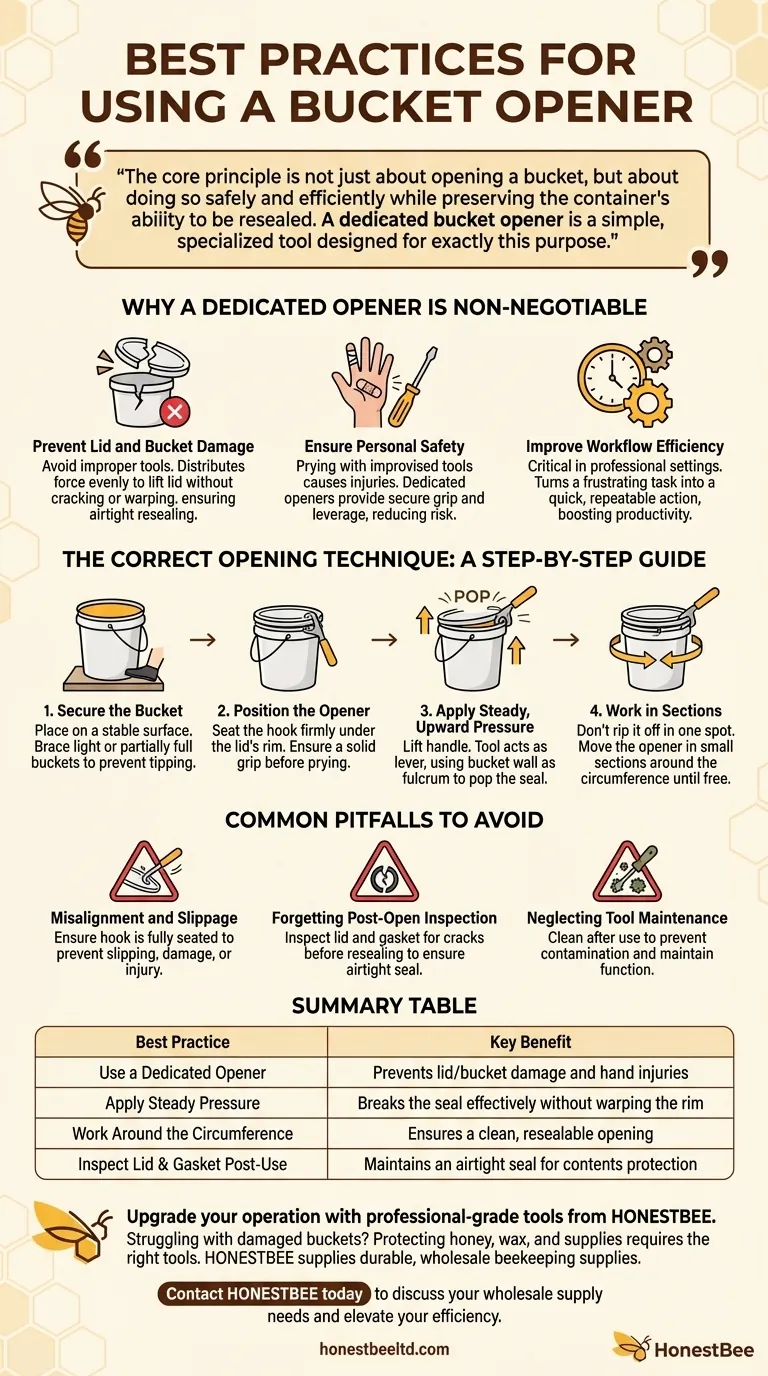

The core principle is not just about opening a bucket, but about doing so safely and efficiently while preserving the container's ability to be resealed. A dedicated bucket opener is a simple, specialized tool designed for exactly this purpose.

Why a Dedicated Opener is Non-Negotiable

Many attempt to open sealed buckets with screwdrivers, pry bars, or brute force. This approach is inefficient and often leads to preventable problems. Using the correct tool is a matter of safety and asset preservation.

Prevent Lid and Bucket Damage

Improper tools concentrate force on a single point, which can easily crack the plastic lid or warp the bucket's rim. A damaged rim prevents the lid from creating an airtight seal when replaced, potentially ruining the contents. A bucket opener distributes the prying force evenly across its hook, lifting the lid without causing damage.

Ensure Personal Safety

Prying with a sharp or improvised tool is a common cause of hand injuries. A slipping screwdriver can easily cause a puncture wound. A dedicated opener is designed with a handle that provides a secure grip and leverage, significantly reducing physical strain and the risk of accidents.

Improve Workflow Efficiency

In professional settings like foodservice, construction, or brewing, time is critical. A bucket opener turns a frustrating task into a simple, repeatable action. It allows you to access materials quickly and move on, which is essential when dealing with dozens of buckets a day.

The Correct Opening Technique: A Step-by-Step Guide

The process is straightforward but relies on proper technique for the best results.

Step 1: Secure the Bucket

Place the bucket on a stable, flat surface. If the bucket is light or only partially full, you may need to brace it with your foot or other hand to prevent it from tipping as you apply pressure.

Step 2: Position the Opener

Seat the claw or hook of the bucket opener firmly under the edge of the lid. Ensure it has a solid grip on the lid's rim before you begin to pry.

Step 3: Apply Steady, Upward Pressure

Lift the handle upward. The tool acts as a simple lever, using the top of the bucket wall as a fulcrum to pop the lid's seal. You will hear a distinct "pop" as the seal is broken in that section.

Step 4: Work in Sections

Do not try to rip the entire lid off from one spot. After the first pop, slide the opener a few inches along the rim and repeat the process. Continue this motion around the entire circumference of the lid until it is completely free.

Common Pitfalls to Avoid

While simple, there are a few common mistakes that can undermine the tool's effectiveness. Paying attention to these details ensures a perfect result every time.

Misalignment and Slippage

The most common error is not seating the hook fully under the lid's rim. A partial grip can cause the tool to slip off while applying pressure, which can scuff the lid or jar your hand. Take a moment to ensure it is secure before lifting.

Forgetting Post-Open Inspection

After removing the lid, briefly inspect it and its rubber gasket (if present) for any cracks or damage. This is especially critical if you plan to reseal the bucket to protect its contents from air or moisture. A compromised gasket means the seal will fail.

Neglecting Tool Maintenance

In food service or brewing, a dirty tool can introduce contamination. In painting or construction, dried material on the tool can interfere with its function. Clean your bucket opener after use and store it in a dry place.

Making the Right Choice for Your Goal

Your specific use case determines which best practices are most critical.

- If your primary focus is food service or brewing: Your top priority is sanitation and preserving the seal. Always clean the tool before use and inspect the lid's gasket after opening to ensure resealability.

- If your primary focus is construction or paint: Your main goal is efficiency and reusability. A clean open allows you to reseal buckets tightly, protecting expensive materials from drying out.

- If your primary focus is occasional home or farm use: Your goal is safety and avoiding frustration. Simply having and using the right tool prevents injuries and damage to your containers.

By adopting this simple tool and technique, you replace frustration with reliable and professional execution.

Summary Table:

| Best Practice | Key Benefit |

|---|---|

| Use a Dedicated Opener | Prevents lid/bucket damage and hand injuries |

| Apply Steady Pressure | Breaks the seal effectively without warping the rim |

| Work Around the Circumference | Ensures a clean, resealable opening |

| Inspect Lid & Gasket Post-Use | Maintains an airtight seal for contents protection |

Upgrade your operation with professional-grade tools from HONESTBEE.

Are you a commercial apiary or beekeeping equipment distributor struggling with damaged buckets and inefficient workflows? Using the right tools, like a proper bucket opener, is just as critical for protecting your valuable honey, wax, and supplies as having reliable beekeeping equipment.

HONESTBEE supplies durable, wholesale-focused beekeeping supplies and equipment designed for the demands of professional operations. Let us help you work smarter and safer.

Contact HONESTBEE today to discuss your wholesale supply needs and elevate your efficiency.

Visual Guide

Related Products

- 5 Gallon Pail Opener Bucket Opener Tool for Honey Bucket

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 10L Stainless Steel Electric Honey Press Machine

- Classic Drum Shaped Glass Honey Jar with Airtight Lid

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- What are the steps for operating a bucket honey press? Efficiently Extract Thick Honey and High-Quality Wax

- What are some common uses for bucket openers? Essential for Safety & Efficiency in Commercial Operations

- What are the main benefits of using a bucket opener? Enhancing Safety and Preservation

- Why is automated packaging machinery essential for scaling industrial honey production? Drive Commercial Scalability

- What is a bucket opener and what is its primary function? Open Pails Safely & Preserve Seals