To construct a functional top-bar hive, you must focus on three critical measurements. The top-bars must be exactly 1 and 3/8 inches wide, the side walls should be angled at 120 degrees from the bottom board, and there must be a 3/16 inch space between the ends of the top-bars and the front and back walls of the hive. These dimensions are not arbitrary; they are essential for respecting the bees' natural instincts and ensuring the hive is easy to manage.

The success of a top-bar hive isn't determined by its overall size, but by its adherence to the biological principle of "bee space." Getting these few key measurements right prevents a host of management problems by allowing the bees to build comb in a way that is natural for them and predictable for you.

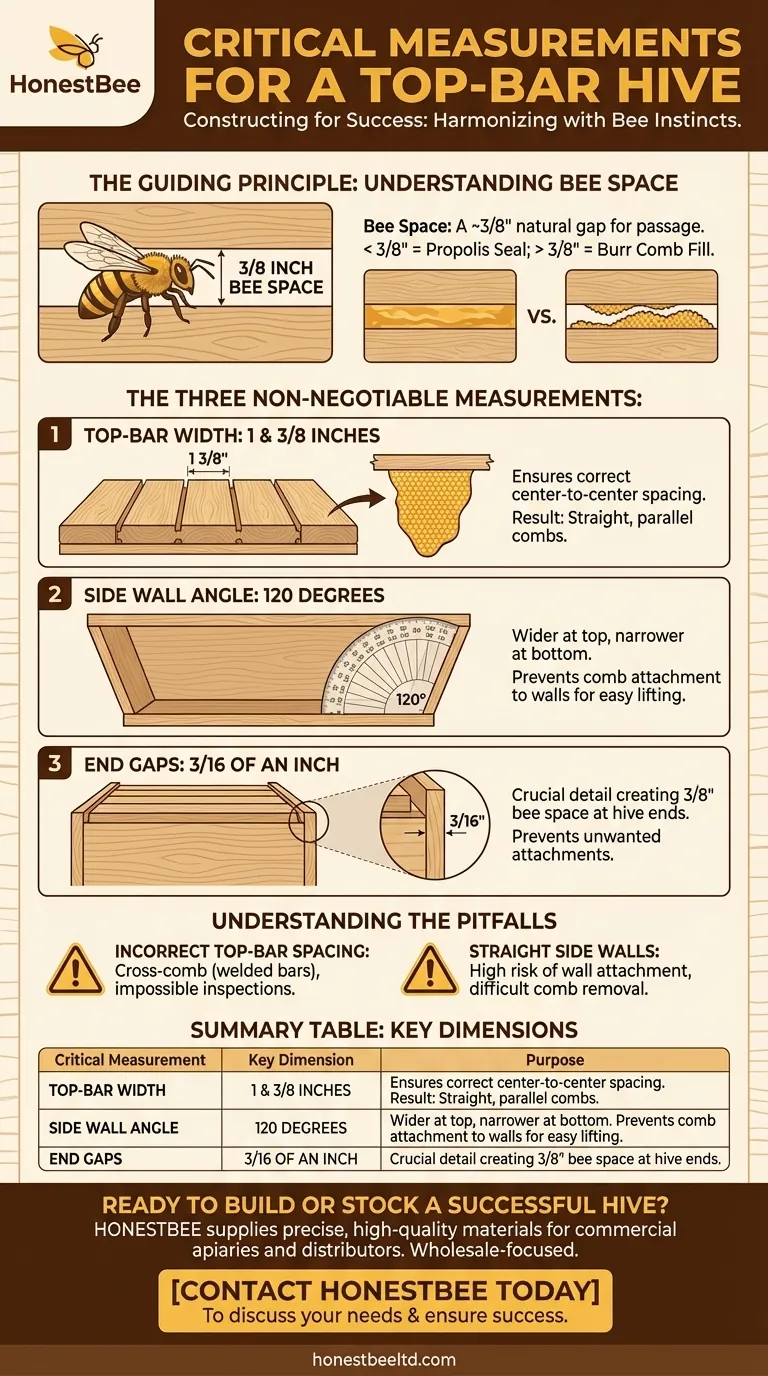

The Guiding Principle: Understanding Bee Space

What is Bee Space?

Bee space is the foundational concept in all modern beekeeping. It refers to a gap of approximately 3/8 of an inch, which bees naturally leave open as a passage or working area.

If a space is smaller than this, bees will seal it with propolis (a resinous bee glue). If a space is larger, they will fill it with "burr comb," which is extra honeycomb built to close the gap.

Why Bee Space Dictates Hive Design

Every critical measurement in a top-bar hive is designed to create and maintain this 3/8 inch bee space. When this space is respected, bees build straight, manageable combs.

When it is violated, the beekeeper is faced with a hive full of cross-combs and propolis-sealed bars, making inspections nearly impossible without destroying the colony's work.

The Three Non-Negotiable Measurements

Top-Bar Width: 1 and 3/8 Inches

This is the single most important measurement. A top-bar width of 1 and 3/8 inches ensures that when the bars are pushed together, the center-to-center distance between combs is precisely what bees would build in nature.

This consistent spacing is what encourages the bees to build straight, parallel combs, with one comb hanging neatly from the center of each bar.

Side Wall Angle: 120 Degrees

The sloped sides of a top-bar hive are a key design feature. By angling the walls at 120 degrees from the floor, you create a space that is wider than a natural comb at the top but narrower at the bottom.

This design strongly discourages the bees from attaching their comb to the side walls of the hive, which makes lifting each bar for inspection clean and simple.

End Gaps: 3/16 of an Inch

A gap of 3/16 of an inch must be maintained between the ends of the top-bar row and the front and rear walls of the hive.

This detail is crucial. This 3/16 inch space, when combined with the space on the other side, creates the perfect 3/8 inch bee space between the hive walls and the first and last combs, preventing unwanted attachments.

Understanding the Pitfalls

The Risk of Incorrect Top-Bar Spacing

If your top-bars are too wide or too narrow, the entire system fails. Bees will build cross-comb across multiple bars, effectively welding them together.

Attempting to inspect a hive with this issue can result in torn comb, spilled honey, and a very defensive colony. Precision here is not optional.

Straight vs. Sloped Sides

While sloped sides are the standard recommendation, some plans use straight sides. Be aware that bees are far more likely to attach comb to straight vertical walls.

This can complicate inspections, as you may have to cut the comb free from the hive body each time you lift a bar, causing stress to both the bees and the beekeeper.

Lid and Ventilation

While not a measurement related to bee space, the lid design is important. It should be constructed to allow for adequate ventilation to manage moisture.

A well-designed lid can often be cracked open or shifted for hive work without having to be removed and placed on the ground, which simplifies the inspection process.

Making the Right Choice for Your Build

Your goal is to construct a hive that works with the bees' instincts, not against them. Focus your precision on the dimensions that directly impact bee behavior.

- If your primary focus is easy and clean inspections: Adhere strictly to the 1 and 3/8 inch top-bar width to ensure perfectly spaced, individual combs.

- If your primary focus is preventing difficult-to-manage comb: Prioritize the 120-degree side wall angle to minimize the bees' impulse to attach comb to the hive body.

- If your primary focus is a fully functional hive: Never neglect the 3/16 inch end gaps, as this detail completes the crucial bee space envelope around the entire comb structure.

By building with these bee-centric dimensions, you are creating a hive that works in harmony with the colony's natural instincts.

Summary Table:

| Critical Measurement | Key Dimension | Purpose |

|---|---|---|

| Top-Bar Width | 1 and 3/8 inches | Ensures correct center-to-center comb spacing for straight, parallel combs. |

| Side Wall Angle | 120 degrees | Prevents bees from attaching comb to the hive walls for easy bar lifting. |

| End Gaps | 3/16 of an inch | Creates the necessary 3/8 inch bee space at hive ends to avoid comb attachment. |

Ready to build or stock a top-bar hive that works in harmony with your bees?

HONESTBEE supplies beekeepers and beekeeping equipment distributors with the precise, high-quality materials needed for successful hive construction. Our wholesale-focused operations ensure you get the right supplies for commercial apiaries and retail sales.

Contact HONESTBEE today to discuss your hive building or equipment supply needs and ensure your success.

Visual Guide

Related Products

- Top Bar Beehive for Beekeeping Wholesales Kenya Top Bar Hive

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

People Also Ask

- What are the key features of the Kenyan Top Bar Hive? A Guide to Simpler, Natural Beekeeping

- Which is better Kenya top bar hive or Langstroth? Choose the Right Hive for Your Goals

- What are the labor requirements for a KTBH vs. Langstroth hive? A Guide for Apiary Efficiency

- What are the benefits of a top bar hive? A Natural, Low-Impact Approach to Beekeeping

- How does wax harvesting differ between a top bar hive and a Langstroth hive? Choose Your Beekeeping Strategy