In short, automatic filling machines provide three transformative advantages: they dramatically increase production speed, deliver unwavering filling accuracy, and offer the scalability needed to grow your business. They are engineered to move beyond the limitations of manual labor, creating a highly efficient and reliable packaging process.

The decision to adopt an automatic filling machine is not merely about increasing output. It's about fundamentally improving product consistency, minimizing costly waste, and building a production line that can scale seamlessly with your market demand.

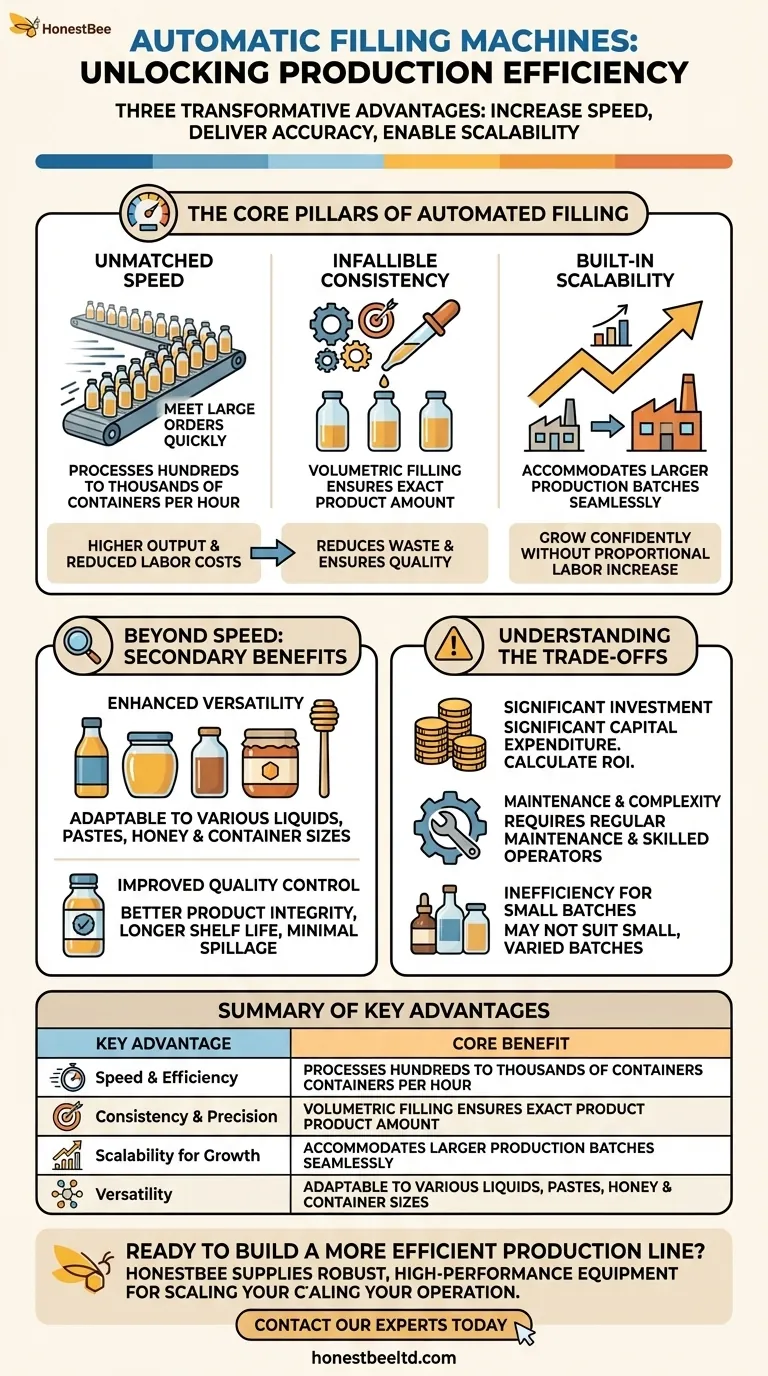

The Core Pillars of Automated Filling

Understanding the key benefits of automatic fillers reveals why they are a cornerstone of modern production. Each advantage addresses a critical bottleneck found in manual or semi-automatic processes.

Unmatched Speed and Production Efficiency

The most immediate impact of an automatic filler is its sheer speed. These machines are designed for high-volume environments.

They can process hundreds or even thousands of containers per hour, a rate that is impossible to sustain manually. This directly translates to higher output, reduced labor costs per unit, and the ability to meet large orders quickly.

Infallible Consistency and Precision

Human error is a natural variable in any manual process. Automatic filling machines eliminate this variable entirely.

Using technologies like volumetric filling, each container receives the exact same amount of product every single time. This precision is critical for reducing product waste from overfills and ensuring every customer receives a consistent, high-quality product.

Built-in Scalability for Growth

An automatic filling machine is an investment in your company's future. It provides the operational capacity to handle significant increases in demand.

As your business grows, the machine can easily accommodate larger production batches without requiring a proportional increase in labor or a decline in quality. This allows you to scale your operations smoothly and confidently.

Beyond Speed: Secondary Operational Benefits

While the core advantages are compelling, several other benefits contribute to a more streamlined and effective operation.

Enhanced Versatility

Modern automatic fillers are not one-trick ponies. They can be configured to handle a wide variety of product types, from thin liquids to thick pastes and honey.

Furthermore, they are often adaptable to different container sizes and shapes, providing the flexibility to launch new product lines without needing entirely new equipment.

Improved Quality Control

By removing air during the filling process and ensuring a perfect seal, these machines contribute to better product integrity and shelf life.

For specialized products like honey sticks, precision engineering ensures minimal spillage and a perfect, mess-free seal, which is crucial for consumer satisfaction and brand reputation.

Understanding the Trade-offs

To make an informed decision, it's essential to recognize that automatic machines are not the right fit for every single scenario.

Significant Initial Investment

The primary barrier to entry is cost. An automatic filling machine represents a significant capital expenditure compared to manual or semi-automatic alternatives. The return on investment must be carefully calculated based on your production volume and labor savings.

Maintenance and Complexity

These are sophisticated pieces of equipment that require regular maintenance and skilled operators. A breakdown can halt production, making a preventative maintenance schedule and technical expertise essential.

Inefficiency for Small, Varied Batches

If your business model relies on producing very small, highly customized batches of many different products, the setup and changeover time for an automatic machine can negate its speed advantage. In such cases, a semi-automatic machine may offer better flexibility.

Making the Right Choice for Your Production Needs

The best solution depends entirely on your specific operational goals and business scale.

- If your primary focus is rapid growth and high-volume output: An automatic filling machine is the only viable path to meeting market demand without compromising quality.

- If your primary focus is maximizing product consistency and reducing waste: The unparalleled precision of an automatic filler will deliver significant ROI by eliminating overfills and ensuring brand integrity.

- If your primary focus is a cost-effective step up from manual labor: A semi-automatic machine provides a powerful balance of increased efficiency and a lower initial investment.

Ultimately, investing in the right filling technology empowers you to build a more efficient, reliable, and scalable production line.

Summary Table:

| Key Advantage | Core Benefit |

|---|---|

| Speed & Efficiency | Processes hundreds to thousands of containers per hour, reducing labor costs. |

| Consistency & Precision | Eliminates human error with volumetric filling, minimizing product waste. |

| Scalability for Growth | Accommodates larger production batches seamlessly as your business expands. |

| Versatility | Adaptable to various products (liquids, pastes, honey) and container sizes. |

Ready to build a more efficient and scalable production line?

At HONESTBEE, we supply the robust, high-performance beekeeping and honey processing equipment that commercial apiaries and distributors rely on. An automatic filling machine is a cornerstone investment for scaling your honey packaging operation, ensuring product consistency and meeting market demand.

Contact our experts today to discuss how our wholesale-focused solutions can empower your business growth.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

People Also Ask

- How do automated filling and labeling systems ensure EU compliance? Master Honey Regulations with Precision Technology

- What are the best practices for achieving professional-looking honey bottling results? Master the Art of Honey Packaging

- How do professional honey filling and packaging machines enhance the economic value of stingless bee honey products?

- What are the technical advantages of industrial-grade honey filling machines? Optimize Your Honey Processing Line

- How do automated filling and packaging machines contribute to the commercial value of propolis? Maximize Your ROI

- How do honey filling and packaging machines assist in increasing the added value of beekeeping products for brands?

- How does a semi-automatic filling machine operate? Boost Your Production Consistency

- Why must honey filling machinery use 316L stainless steel? Ensure Food Safety and Prevent Corrosion