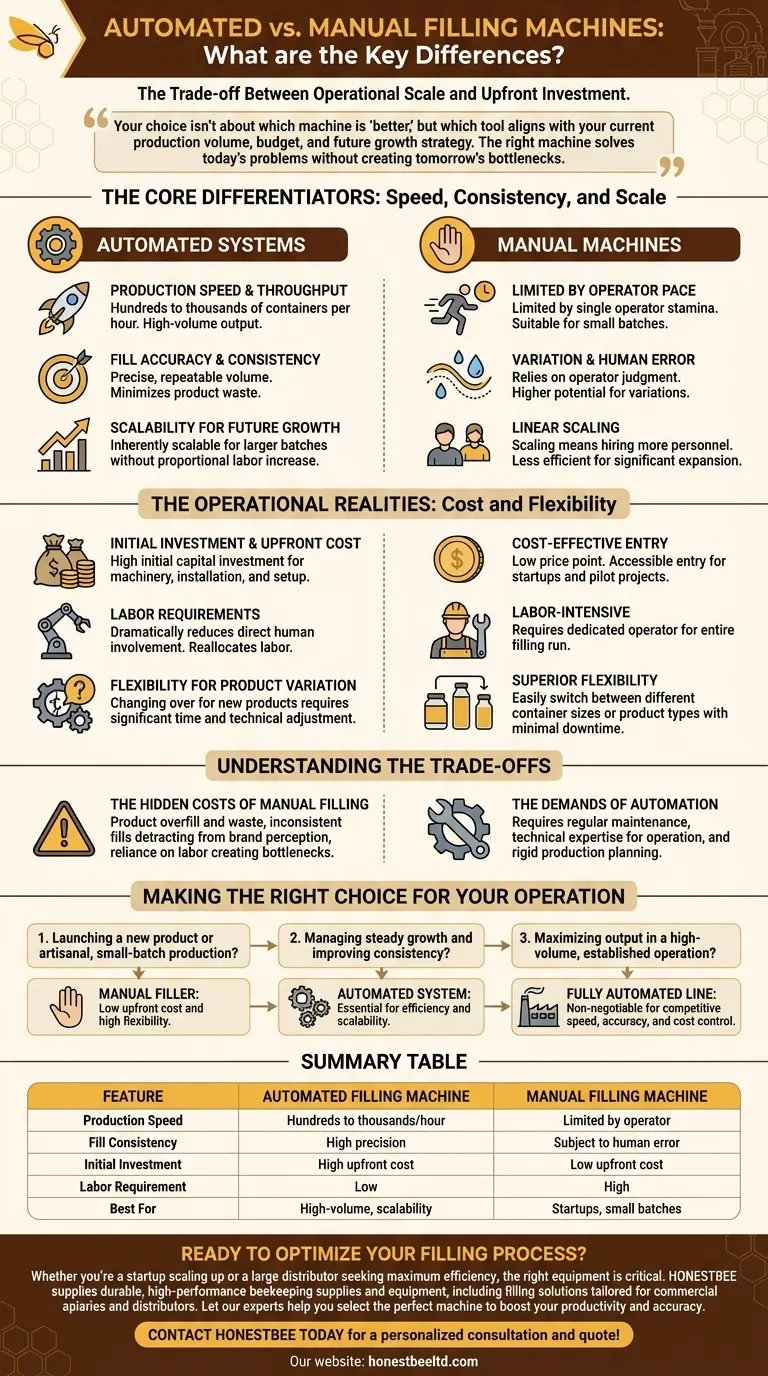

The fundamental difference between automated and manual filling machines lies in a trade-off between operational scale and upfront investment. Automated systems deliver high speed, consistency, and scalability at a higher initial cost, while manual machines offer flexibility and a low barrier to entry for smaller-scale operations.

Your choice isn't about which machine is "better," but which tool aligns with your current production volume, budget, and future growth strategy. The right machine solves today's problems without creating tomorrow's bottlenecks.

The Core Differentiators: Speed, Consistency, and Scale

The primary advantages of automation are quantitative and directly impact your production ceiling.

Production Speed and Throughput

An automated filling machine is designed for high-volume output. These systems can process hundreds or even thousands of containers per hour, a rate impossible to match with human labor.

A manual filler's speed is entirely limited by the pace and stamina of a single operator. This makes it suitable for small batches but a significant constraint on growth.

Fill Accuracy and Consistency

Automation excels at dispensing a precise, repeatable volume of product into every container. This consistency minimizes product waste and ensures a uniform customer experience.

Manual filling relies on an operator's judgment and skill, which can lead to variations from one container to the next. This introduces a higher potential for human error, affecting both cost and product presentation.

Scalability for Future Growth

Automated lines are inherently scalable. As your production demands increase, these systems can handle larger batches and faster run times without a proportional increase in labor.

Scaling up with manual filling means hiring more personnel. This linear relationship between output and labor costs makes it a less efficient path for significant expansion.

The Operational Realities: Cost and Flexibility

Beyond raw performance, the financial and operational footprint of each machine type is a critical factor.

Initial Investment and Upfront Cost

The most significant barrier to automation is the high initial capital investment. The machinery, installation, and setup represent a substantial upfront cost.

Manual filling machines are far more cost-effective to purchase. Their low price point makes them an accessible entry for startups, pilot projects, or businesses with limited capital.

Labor Requirements

Automated systems dramatically reduce the need for direct human involvement in the filling process. Labor can be reallocated to supervision, quality control, and other higher-value tasks.

Manual fillers are labor-intensive by definition, requiring a dedicated operator for the entire duration of the filling run.

Flexibility for Product Variation

Manual machines offer superior flexibility for diverse or frequently changing products. An operator can easily switch between different container sizes or product types with minimal downtime.

While modern automated systems are becoming more flexible, changing over a line for a new product or container often requires more significant time and technical adjustment.

Understanding the Trade-offs

Choosing a system requires a clear-eyed view of the potential downsides of each approach.

The Hidden Costs of Manual Filling

While cheap to acquire, manual filling can incur costs through product overfill and waste. Furthermore, inconsistent fills can detract from brand perception, and reliance on labor can create production bottlenecks during periods of high demand or staff absence.

The Demands of Automation

An automated system is not a "set it and forget it" solution. It requires a commitment to regular maintenance, technical expertise for operation and troubleshooting, and a more rigid production planning process to justify its high throughput.

Making the Right Choice for Your Operation

Select the technology that best serves your specific business objectives.

- If your primary focus is launching a new product or artisanal, small-batch production: A manual filler is the logical choice for its low upfront cost and high flexibility.

- If your primary focus is managing steady growth and improving consistency: An automated system is essential for achieving the efficiency and scalability needed to meet rising demand.

- If your primary focus is maximizing output in a high-volume, established operation: A fully automated line is non-negotiable for maintaining competitive speed, accuracy, and cost control.

Ultimately, aligning your equipment with your operational scale is the key to efficient and sustainable production.

Summary Table:

| Feature | Automated Filling Machine | Manual Filling Machine |

|---|---|---|

| Production Speed | Hundreds to thousands of containers per hour | Limited by operator pace and stamina |

| Fill Consistency | High precision, minimal variation | Subject to human error and variation |

| Initial Investment | High upfront cost | Low upfront cost, cost-effective entry |

| Labor Requirement | Low, reallocates personnel to supervision | High, requires dedicated operator |

| Best For | High-volume production, scalability, consistency | Startups, small batches, product flexibility |

Ready to Optimize Your Filling Process?

Whether you're a startup scaling up or a large distributor seeking maximum efficiency, the right equipment is critical. HONESTBEE supplies durable, high-performance beekeeping supplies and equipment, including filling solutions tailored for commercial apiaries and distributors.

Let our experts help you select the perfect machine to boost your productivity and accuracy.

Contact HONESTBEE today for a personalized consultation and quote!

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

People Also Ask

- What technical advantages do honey filling and packaging machines provide? Optimize Your Large-Scale Production

- What role do industrial honey filling machines play in supporting large-scale honey export trade? Scale Globally

- What are the technical advantages of automated honey filling and packaging equipment? Maximize Your Global Market Reach

- What defines a Semi-automated honey filling machine? Precision and Efficiency for Scaling Apiaries

- How does the implementation of industrial-grade packaging equipment impact honey market value? Boost Profits & Brand.

- What are the key characteristics of a honey stick filling machine? High-Precision Packaging Solutions

- How does a piston filling machine work? Master Precision and Efficiency in Honey Packaging

- What is the function of honey extraction and filling machinery in nomadic beekeeping? Optimize Your Processing Hub