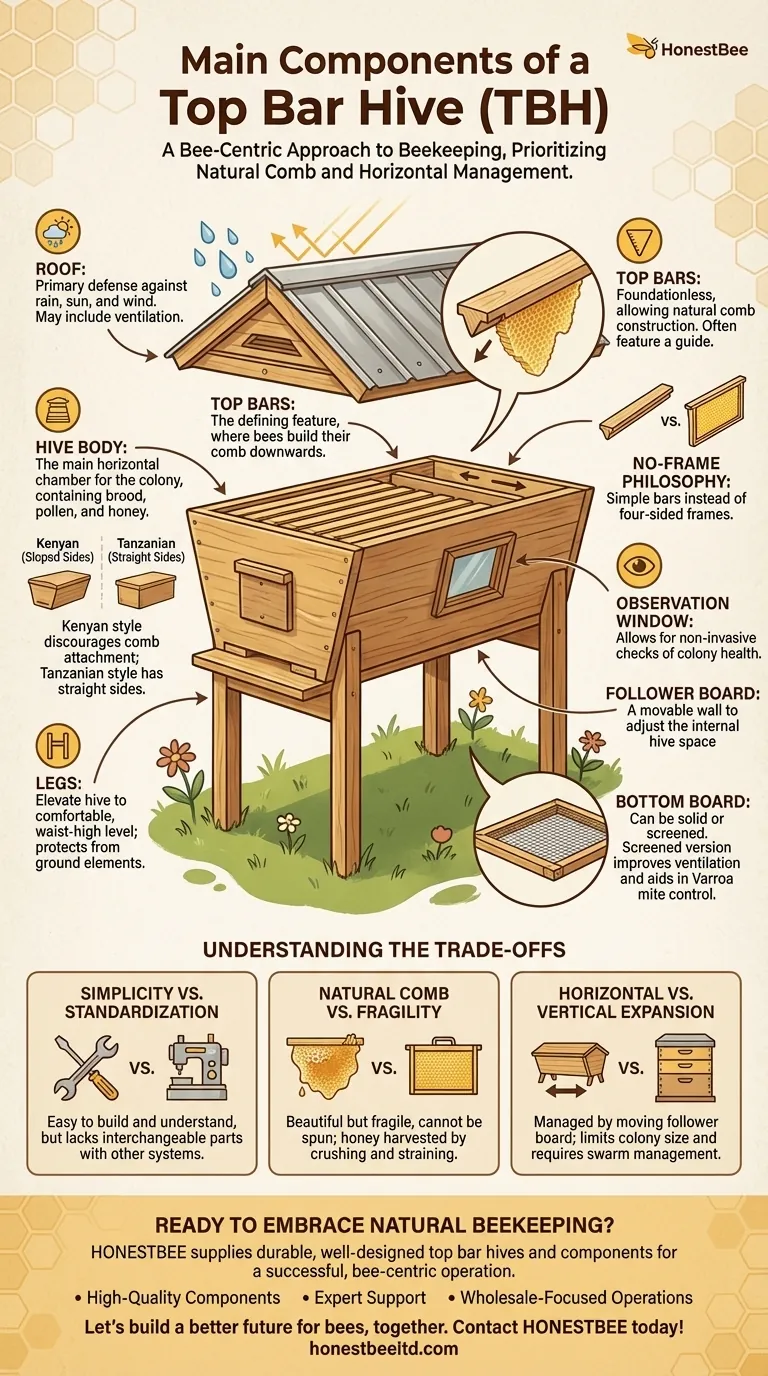

At its core, a top bar hive (TBH) is comprised of a simple horizontal trough, a set of wooden bars that rest on top, and a roof. The essential components are the hive body, the top bars from which bees build their comb, a protective roof, and legs to elevate it. Most designs also include movable follower boards to adjust the hive's internal space.

A top bar hive is defined by its horizontal layout and its use of simple bars instead of four-sided frames. This design prioritizes a more natural, bee-centric approach to beekeeping and requires a different management style than the common vertically-stacking Langstroth hive.

The Core Structure: The Hive Body and Its Support

The main body of the hive provides the essential shelter and workspace for both the bees and the beekeeper. Its design is fundamental to the hive's function.

The Hive Body

The hive body is the long, horizontal trough that contains the entire colony. It acts as a single, elongated chamber for the brood, pollen, and honey.

There are two primary styles: the Kenyan hive, which has sloped sides, and the Tanzanian hive, which has straight, rectangular sides. The sloped sides of the Kenyan design are intended to discourage bees from attaching their comb to the hive walls, making inspections easier.

The Legs

Legs raise the entire hive body to a comfortable, waist-high working level. This is a key ergonomic feature of the top bar hive, as it eliminates the heavy lifting of stacked boxes associated with other hive types.

The elevation also helps protect the colony from ground moisture, pests, and predators.

The Roof

The roof is the hive's primary defense against the elements, shielding the colony from rain, sun, and wind. Roofs can be flat, gabled, or hinged for easy access.

A well-designed roof provides protection and may also incorporate ventilation to help manage temperature and humidity inside the hive.

The Heart of the Hive: Top Bars and Natural Comb

The top bars are the single most defining feature of this hive style. They dictate how the bees build their home and how the beekeeper interacts with the colony.

Understanding Top Bars

Top bars are simply wooden slats that are laid across the top of the hive body, sitting side-by-side to form a complete ceiling. Each bar serves as the starting point for a single curtain of honeycomb.

Bees build their comb downwards from these bars, drawing it out naturally without the constraints of a pre-made foundation.

The "No-Frame" Philosophy

Unlike the four-sided frames used in Langstroth hives, top bars are just that—bars. This foundationless approach allows bees to determine the cell size and structure of their comb, which is a core tenet of natural beekeeping.

Guiding the Comb

To encourage bees to build straight, orderly combs that don't get stuck together, top bars often feature a guide. This can be a simple wooden wedge, a thin strip of wood, or a line of melted beeswax along the center of the bar's underside.

Managing the Colony: Key Internal Components

Beyond the basic structure, several components are critical for effective colony management and observation.

The Follower Board

A follower board is a solid panel shaped to fit the internal profile of the hive. It acts as a movable wall, allowing the beekeeper to adjust the size of the space the bees occupy.

This is crucial for helping a small colony regulate its temperature or for confining the bees to one section of the hive during inspections or honey harvesting.

The Observation Window

Many top bar hives include a viewing window built into the side of the hive body, often covered by a small shutter. This is a highly valued feature, as it allows the beekeeper to check on the colony's progress and health with minimal disturbance.

The Bottom Board

The floor of the hive, or bottom board, can be solid or screened. A screened bottom board is a popular option that provides excellent ventilation and serves as a vital tool for monitoring and managing Varroa mites, a common and destructive honeybee parasite.

Understanding the Trade-offs

The simplicity of the top bar hive is its greatest strength, but it also comes with distinct considerations compared to other systems.

Simplicity vs. Standardization

The TBH is easy to build and understand, often from simple plans and basic materials. However, it lacks the standardized, interchangeable components of the Langstroth system, making it harder to source replacement parts or exchange frames with other beekeepers.

Natural Comb vs. Fragility

The natural, foundationless comb is beautiful but also fragile. It cannot be spun in a centrifugal honey extractor and must be handled with care, especially in warm weather when the wax is soft. Honey is typically harvested by crushing and straining the comb.

Horizontal vs. Vertical Expansion

Expansion is managed horizontally by moving the follower board, not vertically by adding boxes. This limits the ultimate size of a single colony and means swarm management is a critical skill for the top bar beekeeper.

Making the Right Choice for Your Beekeeping Goals

Choosing a hive style is the first major decision in a beekeeper's journey. Your choice should be guided by your personal goals and beekeeping philosophy.

- If your primary focus is a natural, low-intervention approach: The TBH is an excellent choice, as it allows bees to build comb and organize their colony according to their own instincts.

- If your primary focus is maximizing honey production: The Langstroth hive is generally more efficient for large-scale honey harvests due to its interchangeable frames and compatibility with extraction equipment.

- If your primary focus is accessibility and avoiding heavy lifting: The waist-high, single-box design of the TBH makes it physically less demanding to manage than vertically-stacking hives.

Ultimately, understanding these core components empowers you to choose the hive that best aligns with the kind of beekeeper you want to become.

Summary Table:

| Component | Key Function | Key Feature |

|---|---|---|

| Hive Body | Main horizontal chamber for the colony | Kenyan (sloped) or Tanzanian (straight) styles |

| Top Bars | Foundation for bees to build natural comb | Foundationless design with a central guide |

| Roof & Legs | Protection from elements & ergonomic access | Elevates hive to waist height |

| Follower Board | Adjusts internal hive space for colony management | A movable wall for temperature control |

| Observation Window | Allows for non-invasive colony checks | Minimizes disturbance to the bees |

| Bottom Board | Hive floor; can be solid or screened | Screened version aids in ventilation & mite control |

Ready to Embrace Natural Beekeeping?

Whether you're a commercial apiary or a beekeeping equipment distributor, the right equipment is the foundation of a healthy, productive colony. HONESTBEE supplies the durable, well-designed top bar hives and components that support a successful, bee-centric operation.

We provide:

- High-Quality Components: Durable hive bodies, precisely crafted top bars, and protective roofs built to last.

- Expert Support: Guidance on the best hive configurations for your specific goals and environment.

- Wholesale-Focused Operations: Competitive pricing and reliable supply for commercial beekeepers and distributors.

Let's build a better future for bees, together. Contact HONESTBEE today to discuss your hive supply needs!

Visual Guide

Related Products

- Top Bar Beehive for Beekeeping Wholesales Kenya Top Bar Hive

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

People Also Ask

- What are the benefits of a top bar beehive? Ergonomic Design for Easier, Strain-Free Beekeeping

- What are the benefits of a top bar hive? A Natural, Low-Impact Approach to Beekeeping

- What are the key features of the Kenyan Top Bar Hive? A Guide to Simpler, Natural Beekeeping

- What are the advantages of harvesting honey from a top bar hive? Low-Cost, Simple Harvesting for Beekeepers

- Why are hive inspections easier with Top Bar Hives? Achieve a Calmer, Safer Approach to Beekeeping