In short, the three primary types of volumetric filling machines are piston fillers, gravity-fed fillers, and pump fillers. Each operates on a distinct mechanical principle, making it uniquely suited for different product viscosities and production requirements. Choosing the correct type is critical for ensuring accuracy, efficiency, and product integrity.

The decision between volumetric filler types is not about which machine is "best," but which dispensing method is right for your product's specific characteristics. Your product's viscosity—its thickness or resistance to flow—is the single most important factor in this choice.

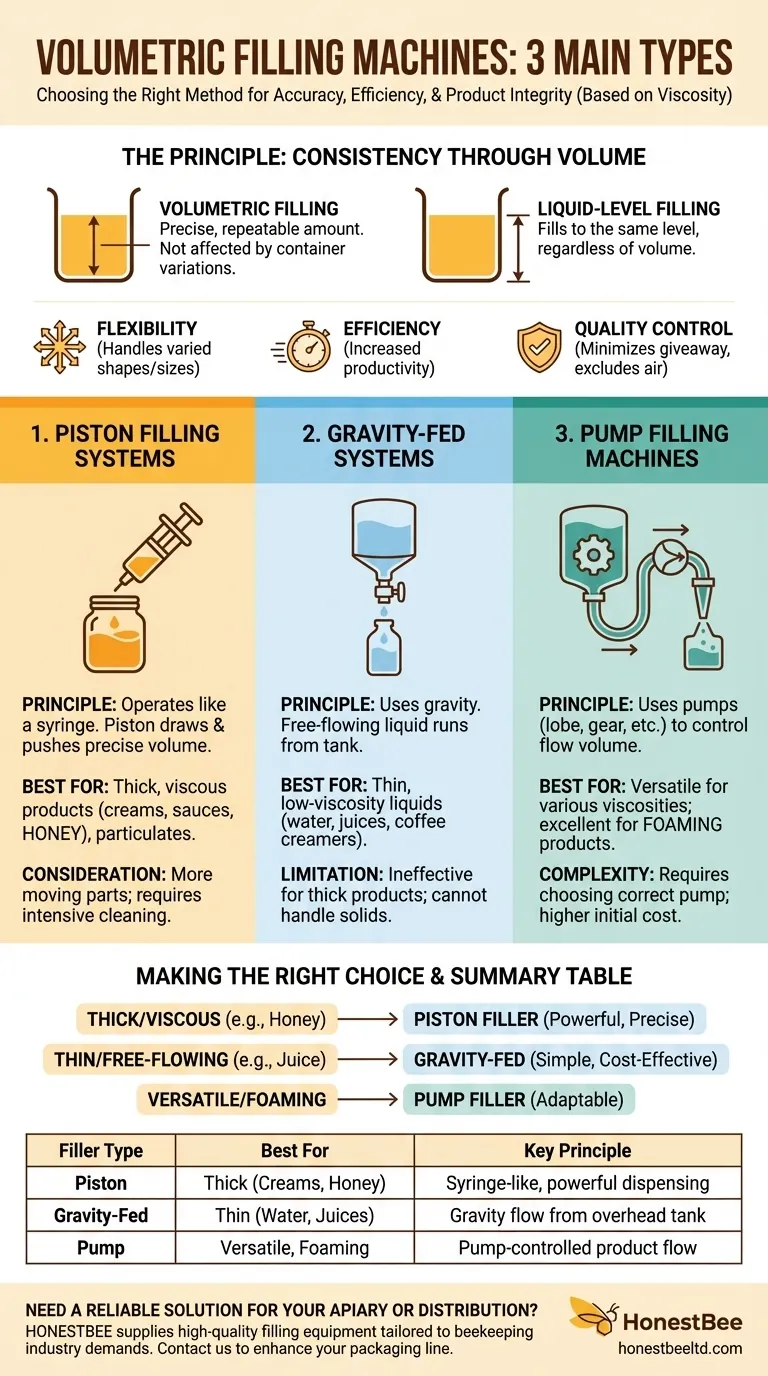

The Principle of Volumetric Filling

Consistency Through Volume, Not Level

A volumetric filler is engineered to dispense a precise, repeatable amount of product into every container. This is fundamentally different from a liquid-level filler, which fills each container to the same height.

By focusing on volume, these machines guarantee that each container holds the same amount of product, even if there are minor manufacturing variations in the containers themselves.

Core Benefits of the Volumetric Approach

Across all types, volumetric fillers provide significant operational advantages. They offer the flexibility to handle a wide range of container shapes and sizes, from small tubes to large tins.

This leads to increased efficiency and productivity while ensuring consistent quality control by minimizing product giveaway and excluding air during the fill cycle.

The Three Main Types of Volumetric Fillers

Understanding how each machine works is key to matching it with your product.

Piston Filling Systems

A piston filler operates like a large syringe. A piston retracts within a cylinder, drawing a precise volume of product from a hopper. The piston then pushes forward, dispensing that exact volume into the container.

This mechanism provides the power needed to move thick, viscous products. It is the ideal choice for materials like heavy creams, lotions, sauces, honey, or even products with particulates.

Gravity-Fed Systems

This is the simplest design. The product is held in a tank located above the filling nozzles. When the valve opens, gravity causes the free-flowing liquid to run down and fill the container below.

Because it relies solely on gravity, this method is best suited for thin, low-viscosity liquids that flow easily, such as water, juices, and coffee creamers.

Pump Filling Machines

Pump fillers use a variety of pump types (such as a lobe, gear, or progressive cavity pump) to move the product from a supply tank to the container. The volume is controlled by precisely managing the pump's operation.

This design is highly versatile and can be configured to handle a wide spectrum of product viscosities, from thin liquids to medium-thick creams. It is also an excellent choice for products that tend to foam.

Understanding the Trade-offs

No single solution is perfect for every application. Each machine type comes with its own set of considerations.

Piston Filler Considerations

The mechanical force that makes piston fillers great for thick products also means they have more moving parts. This can translate to more intensive cleaning and maintenance procedures compared to simpler systems.

Gravity-Fed Limitations

The primary limitation of gravity fillers is their dependence on product viscosity. They are ineffective for thick or slow-moving products and cannot handle anything with suspended solids or chunks.

Pump Filler Complexities

While highly versatile, the effectiveness of a pump filler depends on choosing the correct type of pump for the product. This adds a layer of decision-making and can sometimes result in a higher initial equipment cost.

Making the Right Choice for Your Product

Your product's physical properties should guide your decision to ensure optimal performance and quality.

- If your product is thick, viscous, or contains particulates (like honey or thick sauces): A piston filler provides the positive displacement force required for accurate and clean filling.

- If your product is a thin, free-flowing liquid (like juice or water): A gravity-fed system offers a simple, reliable, and cost-effective solution.

- If you need versatility for a range of viscosities or handle foaming products: A pump filling machine delivers the most adaptable performance for diverse or challenging liquid types.

By matching the machine's mechanism to your product's nature, you can build a filling process that is both highly efficient and consistently reliable.

Summary Table:

| Filler Type | Best For | Key Principle |

|---|---|---|

| Piston Filler | Thick, viscous products (creams, sauces, honey) | Operates like a syringe for precise, powerful dispensing |

| Gravity-Fed Filler | Thin, free-flowing liquids (water, juices) | Uses gravity to fill containers from an overhead tank |

| Pump Filler | Versatile for various viscosities, including foaming products | Employs pumps (lobe, gear, etc.) to control product flow |

Need a reliable filling solution for your apiary or distribution business?

At HONESTBEE, we understand that accurate, efficient filling is critical for commercial beekeepers and equipment distributors. Whether you're packaging honey, creams, or other beekeeping products, selecting the right volumetric filler ensures product integrity and maximizes your operational efficiency.

We supply high-quality, durable filling equipment tailored to the unique demands of the beekeeping industry. Our experts can help you choose the perfect piston, gravity-fed, or pump filler to match your product's specific viscosity and your production volume.

Contact HONESTBEE today to discuss your filling needs and discover how our wholesale-focused solutions can enhance your packaging line's performance and reliability.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

People Also Ask

- What are the benefits of using automated honey-filling machinery? Boost Efficiency and Value for Commercial Apiaries

- Why are high-precision honey filling machines necessary? Elevate Your Commercial Beekeeping Brand and Safety

- What is the economic significance of using honey-filling machines? Boost Profits and Secure Pollination Services

- How do Automated Filling and Capping Equipment help maintain the long-term physicochemical stability of honey?

- Why must advanced automated honey filling and packaging equipment be used? Secure Medicinal-Grade Purity and Bioactivity

- What is the purpose of the cutter in a honey stick machine? The Key to Perfect, Single-Serve Packaging

- What advantages do professional honey-filling machines provide? Boost Commercial Stingless Bee Honey Production

- How does the use of professional honey filtration and filling machinery facilitate international honey exports?