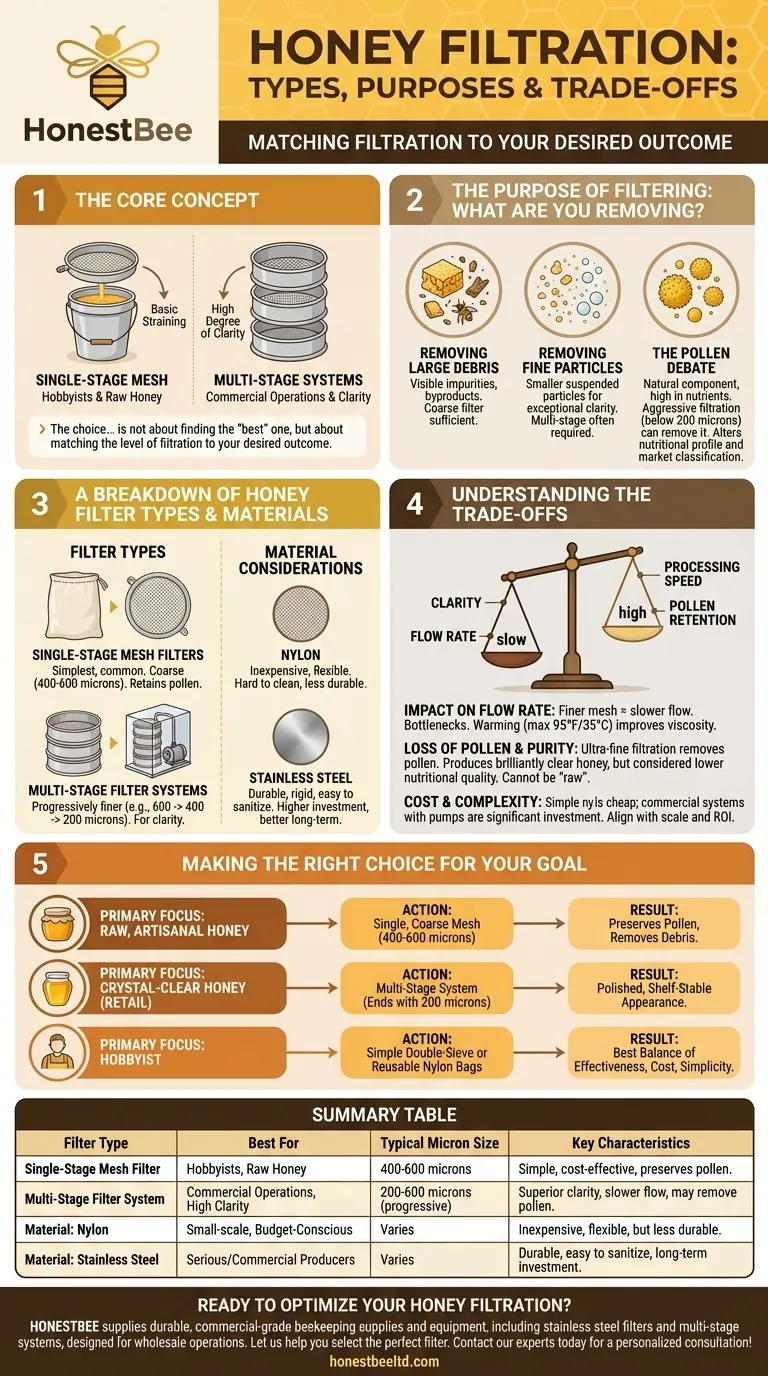

At its core, honey filtration involves choosing between two primary approaches: single-stage mesh filters and multi-stage filter systems. Single-stage filters are simple screens designed for basic straining, ideal for hobbyists, while multi-stage systems use a series of progressively finer filters to achieve a high degree of clarity for larger or commercial operations.

The choice of a honey filter is not about finding the "best" one, but about matching the level of filtration to your desired outcome. Your decision will directly impact the honey's clarity, its processing time, and whether it retains beneficial compounds like pollen.

The Purpose of Filtering: What Are You Removing?

Before choosing a filter, you must first understand what you are trying to separate from the honey. The goal of filtration, or more accurately "straining," is to produce clean, appealing honey without damaging its natural qualities.

Removing Large Debris

This is the most basic and essential step for all honey processing. The goal is to remove visible impurities that are byproducts of the extraction process.

These particles include bits of beeswax, wood from the frames, and unfortunate bee parts. A coarse filter is sufficient for this task.

Removing Fine Particles

For honey that is exceptionally clear, a finer level of filtration is required. This process targets smaller suspended particles that contribute to a cloudy appearance.

These can include fine wax particles, natural sugar crystals, and air bubbles introduced during extraction. Achieving this level of clarity often requires a multi-stage approach.

The Pollen Debate

Pollen is a natural component of honey and is rich in proteins and nutrients. Many consumers specifically seek out honey with a high pollen count, often marketed as raw honey.

Aggressive, fine filtration (typically below 200 microns) can remove a significant amount of this pollen. This is a critical consideration, as removing pollen can alter the honey's nutritional profile and its market classification.

A Breakdown of Honey Filter Types

The hardware for filtering honey ranges from simple bags to more complex, integrated systems. Your scale of operation will be the primary driver of your choice.

Single-Stage Mesh Filters

These are the simplest and most common filters, often consisting of a nylon bag or a stainless steel mesh screen that fits over a bucket or tank.

They are excellent for small-scale beekeepers whose primary goal is to remove large debris while retaining the honey's natural character, including its pollen. These filters are typically coarse, with mesh sizes ranging from 400 to 600 microns.

Multi-Stage Filter Systems

As the name implies, these systems use two or more filters of progressively finer mesh. A typical setup might start with a 600-micron filter to catch large wax, followed by a 400-micron filter, and finishing with a 200-micron filter for clarity.

These can be as simple as stacking sieves on top of each other or as complex as enclosed systems with pumps used in large commercial packing plants.

Material Considerations: Nylon vs. Stainless Steel

Nylon filters are inexpensive, flexible, and widely available, making them a popular choice for hobbyists. However, they can be difficult to clean thoroughly and may wear out over time.

Stainless steel filters are significantly more durable, rigid, and easier to sanitize. While they represent a higher initial investment, they are a better long-term choice for serious or commercial producers.

Understanding the Trade-offs

Every filtration choice comes with consequences. Optimizing for one attribute, like clarity, often means compromising on another, like processing speed or nutritional content.

The Impact on Flow Rate

The finer the filter mesh, the slower the honey will flow through it. This can create significant bottlenecks in your workflow.

Crystallized honey or cool honey will clog fine filters almost immediately. Some producers gently warm their honey (to no more than 95°F or 35°C) to improve its viscosity, but overheating can destroy beneficial enzymes and aromas.

Loss of Pollen and Purity

Ultra-fine filtration, especially systems that use pressure and diatomaceous earth, removes nearly all suspended particles, including pollen. While this produces brilliantly clear honey, it is considered by many to be a lower-quality product from a nutritional standpoint.

This type of honey can no longer be authentically labeled as "raw" and may be indistinguishable from mass-market imported honey.

Cost and Complexity

A simple nylon straining bag is extremely cheap, while a multi-sieve stainless steel setup can be a moderate investment. Commercial-grade systems with pumps and heating elements represent a significant capital expense.

Your choice must align with the scale of your operation and the return you expect on your final product.

Making the Right Choice for Your Goal

Select your filtration method based on the type of honey you aim to produce and the market you intend to serve.

- If your primary focus is raw, artisanal honey: Opt for a single, coarse mesh filter (around 400-600 microns) to remove debris while preserving all the natural pollen.

- If your primary focus is crystal-clear honey for broad retail: Use a multi-stage system, starting coarse and ending with a fine filter (200 microns), to ensure a polished, shelf-stable appearance.

- If you are a hobbyist with a few hives: A simple double-sieve or a set of reusable nylon bags that fit over a 5-gallon bucket offers the best balance of effectiveness, cost, and simplicity.

Ultimately, the right filter empowers you to produce honey that perfectly matches your vision and the expectations of your customers.

Summary Table:

| Filter Type | Best For | Typical Micron Size | Key Characteristics |

|---|---|---|---|

| Single-Stage Mesh Filter | Hobbyists, Raw Honey | 400-600 microns | Simple, cost-effective, preserves pollen. |

| Multi-Stage Filter System | Commercial Operations, High Clarity | 200-600 microns (progressive) | Superior clarity, slower flow, may remove pollen. |

| Material: Nylon | Small-scale, Budget-Conscious | Varies | Inexpensive, flexible, but less durable. |

| Material: Stainless Steel | Serious/Commercial Producers | Varies | Durable, easy to sanitize, long-term investment. |

Ready to Optimize Your Honey Filtration?

Whether you're a commercial apiary aiming for high-volume clarity or a distributor stocking reliable equipment, the right filtration system is key to product quality and efficiency. HONESTBEE supplies durable, commercial-grade beekeeping supplies and equipment, including stainless steel filters and multi-stage systems, designed for the demands of wholesale operations.

Let us help you select the perfect filter to meet your production goals and your customers' expectations.

Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Professional Stainless Steel Honey Filter with Support Handle

- Two-Stage Plastic Honey Filter for Buckets

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

People Also Ask

- What are the functions and advantages of using honey strainers? Ensure Purity & Quality in Your Harvest

- What are the benefits of drying honey filtering equipment after use? Protect Your Honey Quality & Equipment Investment

- What is the role of filtration in honey processing? Ensure Purity, Clarity, and Shelf Life

- How does automated honey filtration and filling machinery improve quality? Guard Your Apiary Against Pest Contamination

- What filter size for honey? A Beekeeper's Guide to Straining for Clarity and Quality