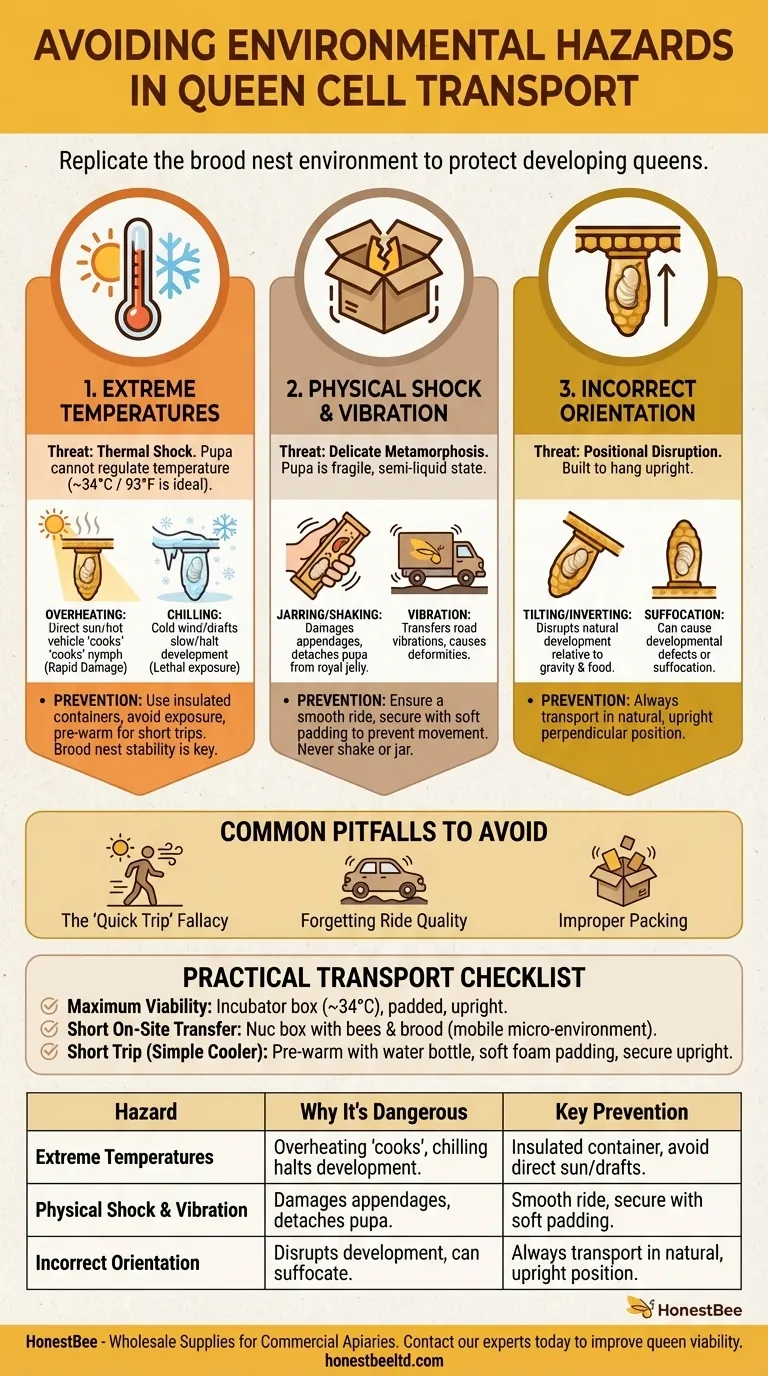

During cell transport, you must avoid three primary environmental hazards: extreme temperatures, physical shock, and incorrect orientation. The developing queen pupa, or nymph, is incredibly fragile and cannot regulate its own temperature or withstand physical force. Exposing queen cells to these stressors, even for a short time, can cause developmental defects or death, nullifying your queen-rearing efforts.

The success of queen cell transport hinges on one principle: replicating the stable, protected environment of the brood nest. Any deviation—whether thermal, physical, or positional—puts the viability of your future queens at significant risk.

The Threat of Thermal Shock

A queen cell's primary defense against the outside world is the stable temperature of the hive, typically around 34°C (93°F). The developing queen pupa has no ability to regulate its own temperature, making it entirely dependent on this external stability.

The Danger of Overheating

Direct sunlight or the inside of a hot vehicle can rapidly heat a queen cell far beyond safe limits. This essentially "cooks" the delicate nymph, causing irreversible damage or immediate death.

Even a few minutes of exposure to hot, direct sunlight can be fatal.

The Risk of Chilling

Conversely, the queen nymph is highly susceptible to chill. Cold winds or a cool atmosphere will quickly draw heat from the cell, slowing or halting development.

Prolonged exposure to cold is just as lethal as overheating and is a common cause of transport failure.

The Importance of Speed and Insulation

The longer a cell is outside the hive, the greater the risk of thermal stress. This is why you must not leave cells exposed for any length of time.

Plan your transport to be as quick as possible, and use an insulated container to buffer the cells against temperature fluctuations during the journey.

The Impact of Physical Disturbance

Inside the cell, the queen is undergoing metamorphosis. Her wings, legs, and internal organs are in a delicate, semi-liquid state. Physical force can easily cause crippling deformities.

Why Shaking and Jarring are Critical Risks

A sharp jolt or constant vibration can damage the pupa's developing appendages or, worse, detach her from the royal jelly at the base of the cell.

This is why you must never shake or jar combs or bars holding queen cells. A smooth ride is not a suggestion; it is a requirement.

The Problem with Incorrect Orientation

Queen cells are built to hang in a natural, perpendicular position. The pupa develops in this specific orientation relative to gravity and its food source.

Tilting or inverting the cells for any significant period can disrupt this positioning, potentially causing developmental problems or suffocation. Always transport cells in the same upright position they held in the hive.

Understanding the Common Pitfalls

Even beekeepers with good intentions can make critical mistakes during transport. Being aware of these common pitfalls is key to avoiding them.

The "Quick Trip" Fallacy

Many assume a short walk from the apiary to a climate-controlled vehicle is safe. However, this is often the most dangerous part of the journey. A sudden gust of cold wind or a moment in the hot sun can be all it takes to ruin a batch of cells.

Forgetting the Ride Quality

Focusing solely on temperature is a mistake. Placing cells in a secure box but then driving over a bumpy field or road defeats the purpose. The quality of the suspension in your vehicle and your driving style matter immensely.

Improper Packing

Placing cells loosely in a box allows them to roll and strike each other, causing both physical and positional damage. Conversely, packing them too tightly without adequate soft padding can transfer road vibrations directly to the cells.

A Practical Checklist for Safe Transport

Your method should match your situation. Use this guide to ensure the highest chance of success.

- If your primary focus is maximum viability: Use a dedicated, temperature-controlled incubator box set to brood nest temperature (~34°C / 93°F) with padded slots to hold cells upright.

- If you are making a short, on-site transfer: Place the entire cell bar in a nuc box containing frames of bees and brood to create a stable, mobile micro-environment.

- If you must use a simple cooler for a short trip: Pre-warm the cooler with a wrapped warm water bottle and use soft foam padding to secure the cells upright, preventing any movement.

Protecting your queen cells during this vulnerable stage is a direct investment in the future strength and productivity of your apiary.

Summary Table:

| Hazard | Why It's Dangerous | Key Prevention |

|---|---|---|

| Extreme Temperatures | The pupa cannot self-regulate temperature; overheating 'cooks' it, chilling halts development. | Use an insulated container; avoid direct sun and cold drafts. |

| Physical Shock & Vibration | Jarring can damage developing appendages and detach the pupa from its food source. | Ensure a smooth ride; secure cells with soft padding to prevent movement. |

| Incorrect Orientation | Tilting or inverting the cell disrupts natural development and can cause suffocation. | Always transport cells in their natural, upright (perpendicular) position. |

Ensure the Success of Your Queen-Rearing Program

Protecting your investment in queen cells is crucial for maintaining strong, productive colonies. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the reliable, wholesale-focused supplies needed for successful operations—from secure transport containers to essential hive management tools.

Contact our experts today to discuss how our equipment can help you mitigate risks and achieve higher queen cell viability.

Visual Guide

Related Products

- Brown Nicot Queen Cell Cups for Breeding Queen Bees Beekeeping

- JZBZ Push-In Queen Cell Cups for Beekeeping

- Wood and Mesh Push-In Queen Cage

- Queen Bee Marking Pen UNI Medium Point for Queen and Bee Marking

- HONESTBEE Heavy Duty All Metal Frame Wire Crimper Tool

People Also Ask

- What are the advantages of standardized plastic queen cups? Boost Commercial Beekeeping Efficiency and Yield

- Why do bees build queen cups? Decoding Your Hive's Health and Intentions

- What is the purpose of priming cell cups before grafting? Boost Queen Rearing Success

- What are the advantages of silicone molds for queen cell cups? Upgrade Your Queen Rearing Precision

- What is the significance of UV curing in 3D-printed honeybee egg components? Protect Embryos and Boost Strength

- What is the impact of 3D printing precision on polycarbonate queen cell cups? Achieving Higher Acceptance Rates

- What is the function of artificial plastic cell cups in the Doolittle Method? Master Queen Rearing for Your Apiary

- What is the difference between queen cells and worker cells? Unlock the Secrets of Your Hive's Health