To separate beeswax from honey in cappings, beekeepers primarily use uncapping tanks, cappings melters, or screw presses. These tools are designed to handle the sticky mixture of wax and honey that is sliced off the honeycomb before extraction, allowing for maximum recovery of both valuable products.

The choice of separation equipment is not about finding a single "best" tool, but about matching the method to your operational scale. The core trade-off is between a lower initial investment with more manual labor versus a higher investment for automated efficiency and yield.

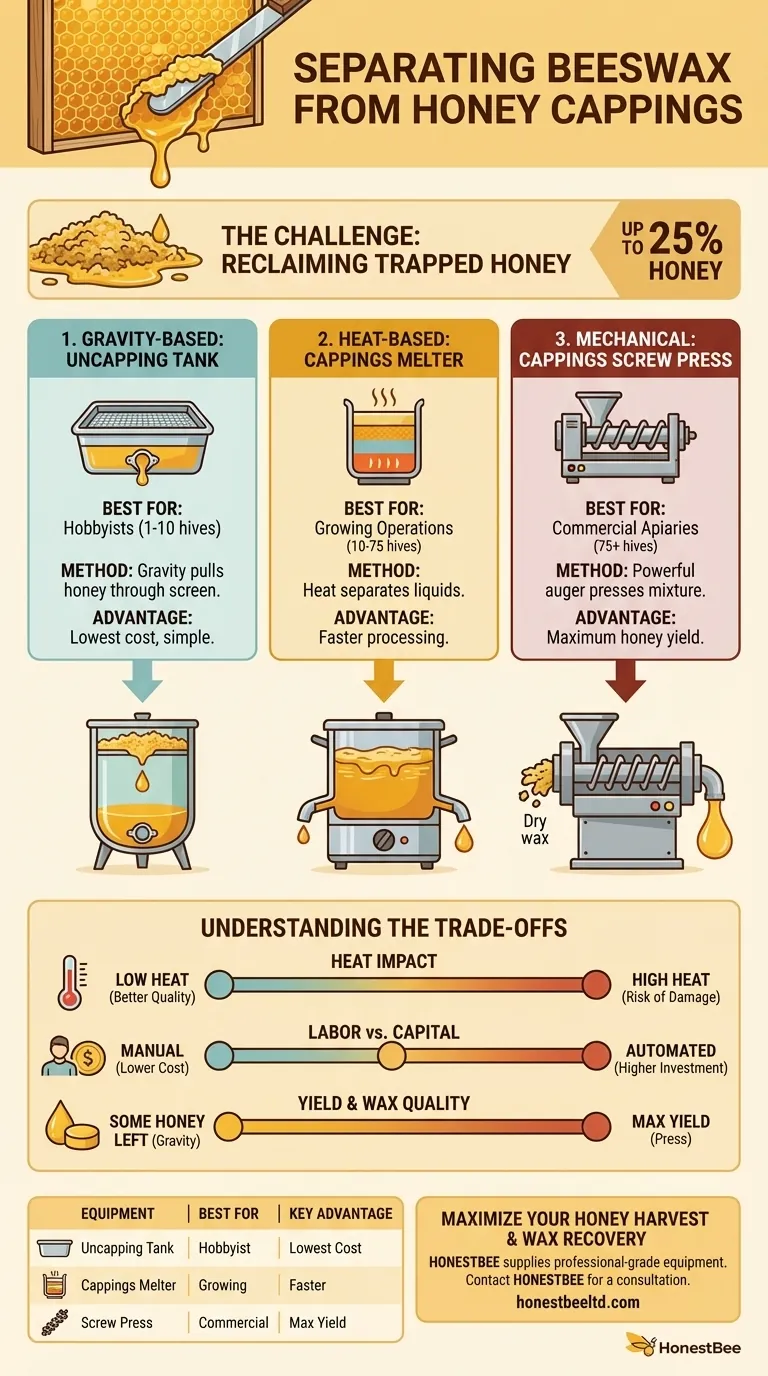

The Core Challenge: Reclaiming Trapped Honey

When you uncap a frame of honey, you slice off the thin beeswax seals, or "cappings," that cover the cells. This process creates a mixture of wax flakes saturated with a significant amount of honey—often up to 25% of the total harvest.

Leaving this honey trapped in the wax is inefficient and wasteful. The goal of separation equipment is to reclaim this honey while preparing the beeswax for rendering.

Methods of Separation: From Manual to Automated

There are three primary methods for separating honey from wax cappings, each with distinct equipment and principles.

Gravity-Based Separation: The Uncapping Tank

An uncapping tank is often the starting point for hobbyist and small-scale beekeepers. It is typically a stainless steel tub with a screen or grid at the bottom and a honey gate or valve.

The process is simple: cappings are sliced off frames and dropped into the tank. Over several hours or days, gravity pulls the denser honey down through the screen, where it collects at the bottom and can be drained off. The wax remains on top of the screen.

After the initial draining, any remaining honey can be washed off the wax with cool water to create a fermented honey-water mixture, which can be used for other purposes.

Heat-Based Separation: The Cappings Melter

A cappings melter uses heat to rapidly separate honey and wax. These devices heat the cappings mixture, causing the wax to melt and float on top of the less-dense, warmed honey.

The separated liquids are then drained through separate spouts. This method is much faster than gravity draining and is favored by beekeepers looking to increase their efficiency.

Common types include water-jacketed melters, which use hot water for gentle, even heating, and direct-heat models.

Mechanical Separation: The Cappings Screw Press

For large-scale and commercial operations, a cappings screw press is the industry standard. This machine uses a powerful auger, or screw, to continuously press the cappings mixture.

The immense pressure forces the honey out through a screen, while the now very dry wax is expelled from the end of the machine. These presses can process hundreds of kilograms per hour, offering the highest throughput and maximum honey yield.

Understanding the Trade-offs

Choosing the right equipment requires understanding the compromises between cost, speed, and product quality.

The Impact of Heat on Honey

The primary drawback of a cappings melter is the use of heat. If not carefully controlled, excessive heat can darken the honey and destroy its delicate aromas and beneficial enzymes. High-quality melters use water jackets to distribute heat gently and minimize this risk.

Labor vs. Capital Investment

An uncapping tank is inexpensive but slow and labor-intensive. A screw press is a significant capital investment but drastically reduces labor and processing time. A melter sits in the middle, offering a balance of speed and cost.

Yield and Wax Quality

A screw press provides the highest honey yield, producing very dry wax pucks. Gravity draining and spinning will always leave some residual honey in the wax, though this can be reclaimed by washing. The wax from a melter is already rendered and clean, while wax from a press or tank needs to be rendered separately.

Choosing the Right Equipment for Your Apiary

Your choice depends entirely on the size of your operation and your primary goals.

- If your primary focus is low-cost hobby beekeeping (1-10 hives): An uncapping tank is the most practical and affordable solution for separating your cappings.

- If your primary focus is growing your operation (10-75 hives): A cappings melter provides a significant boost in efficiency and speed, saving you considerable time during the harvest.

- If your primary focus is commercial production (75+ hives): A cappings screw press is the professional standard for maximizing honey yield and minimizing labor at high volumes.

Understanding these options empowers you to select the precise tool that aligns with your resources and harvesting goals.

Summary Table:

| Equipment | Best For | Primary Method | Key Advantage |

|---|---|---|---|

| Uncapping Tank | Hobbyists (1-10 hives) | Gravity Drainage | Lowest cost, simple operation |

| Cappings Melter | Growing Operations (10-75 hives) | Heat Separation | Faster processing, good efficiency |

| Cappings Screw Press | Commercial Apiaries (75+ hives) | Mechanical Pressing | Maximum honey yield, highest throughput |

Maximize Your Honey Harvest and Wax Recovery

Choosing the right cappings separation equipment is critical for the profitability and efficiency of your apiary. HONESTBEE supplies professional-grade uncapping tanks, cappings melters, and screw presses designed for the specific needs of commercial apiaries and beekeeping equipment distributors.

Our wholesale-focused operations ensure you get durable, high-performance equipment that maximizes your yield and minimizes labor.

Contact HONESTBEE today for a consultation to find the perfect separation solution for your operation's scale and goals.

Visual Guide

Related Products

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Stainless Steel Honey Press Wax Press with Tank

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

People Also Ask

- What are the features of an electric wax melter? Gain Unmatched Control and Consistency

- What are the main advantages of the solar waxer? A Simple, Cost-Free Way to Purify Beeswax

- What are the advantages of using a factory-made steam wax melter? Boost Your Apiary Efficiency and Wax Quality

- What makes the Solar Wax Melter user-friendly? Effortless Wax Rendering for Beekeepers

- What is the principle of operation of a wax melter? Master Efficient Beekeeping Wax Processing

- How does professional beeswax refining equipment increase the value of apiculture byproducts? Maximize Your Profits

- What is the function of portable electromechanical analyzers in beeswax purity screening? Rapid Field Quality Control

- What role do cotton cloth bags play in submerged beeswax extraction? Optimize Your Wax Purity with Simple Filtration