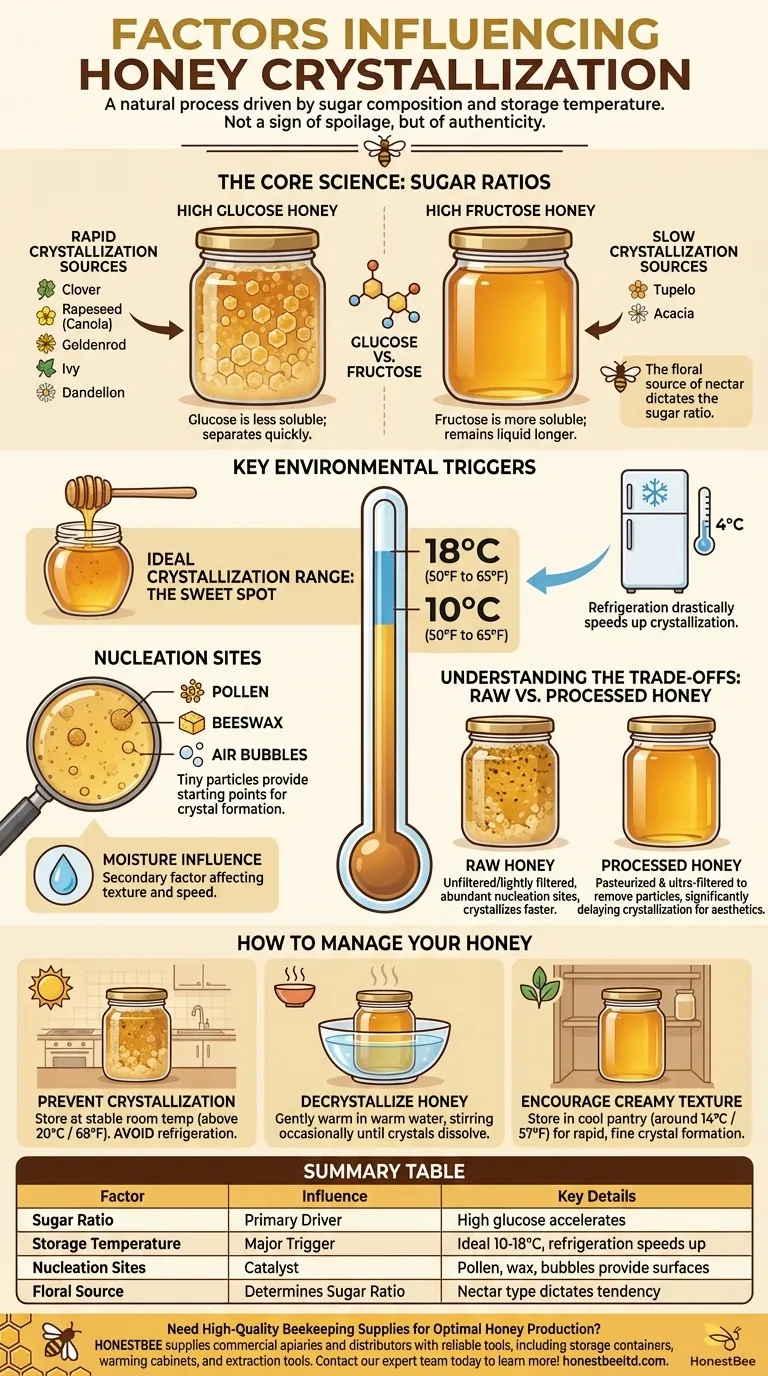

At its core, honey crystallization is a natural process driven by two primary factors: its sugar composition and the temperature at which it is stored. Honey with a higher ratio of glucose to fructose will crystallize much faster, and this process is accelerated significantly when honey is kept in a cool environment, specifically between 10°C and 18°C (50°F and 65°F).

Honey crystallization is not a sign of spoilage or impurity. Instead, it is a natural change that affirms the honey's authenticity, primarily influenced by the type of nectar the bees collected and the temperature of your pantry.

The Core Science: Sugar Ratios Explained

To understand why honey crystallizes, we must first look at its fundamental composition. Honey is a supersaturated solution of sugars, meaning it contains more sugar than can normally remain dissolved.

Glucose vs. Fructose: The Two Key Sugars

Honey is primarily composed of two simple sugars: glucose and fructose. The key difference is that glucose is significantly less soluble in water than fructose.

This imbalance means that in honeys with a high concentration of glucose, the sugar will naturally begin to separate from the water and form tiny crystals.

How Floral Source Dictates the Sugar Ratio

The specific ratio of glucose to fructose in honey is determined almost entirely by the nectar source the bees visited.

Some plants produce nectar that is naturally high in glucose. Honey made from these sources will crystallize very quickly, sometimes within weeks of being harvested.

Honeys Prone to Rapid Crystallization

Common floral sources known for producing high-glucose honey include:

- Clover

- Rapeseed (Canola)

- Goldenrod

- Ivy

- Dandelion

Conversely, honeys like Tupelo or Acacia are high in fructose and can remain liquid for years.

Key Environmental Triggers

While the sugar ratio sets the stage for crystallization, environmental factors act as the trigger, determining how quickly it happens.

The Temperature "Sweet Spot"

The most significant environmental factor is temperature. While cold temperatures encourage crystallization, the ideal range for rapid crystal formation is between 10°C and 18°C (50°F to 65°F).

Storing honey in a refrigerator puts it right in this optimal range, dramatically speeding up the process.

The Importance of "Nucleation Sites"

Crystals need something to form around. In raw, unfiltered honey, these starting points—or nucleation sites—are abundant.

Tiny particles of pollen, bits of beeswax, and even air bubbles suspended in the honey provide the perfect surfaces for glucose crystals to begin growing.

The Minor Influence of Moisture

While less critical than sugar ratio and temperature, moisture content can play a role. Excess moisture can potentially affect the texture and speed of crystallization, though it is a secondary factor.

Understanding the Trade-offs: Raw vs. Processed Honey

The fact that some store-bought honey remains liquid indefinitely is not a sign of higher quality. It is typically the result of commercial processing designed to prevent crystallization for aesthetic reasons.

Why Raw Honey Crystallizes Faster

Raw honey is often unfiltered or lightly filtered, leaving its natural pollen and wax particles intact. These abundant nucleation sites mean raw honey almost always crystallizes faster than its processed counterpart.

The Goal of Commercial Processing

To create a visually appealing, consistently liquid product, large-scale producers often pasteurize (heat) and ultra-filter honey. This process removes the pollen and other particles, eliminating the nucleation sites and significantly delaying crystallization.

How to Manage Your Honey

Understanding the science behind crystallization gives you complete control over your honey's texture.

- If your primary goal is to prevent crystallization: Store your honey at a stable room temperature, ideally above 20°C (68°F). Absolutely avoid storing it in the refrigerator.

- If your honey has already crystallized: Gently place the jar in a bowl of warm (not boiling) water. Let it sit until the crystals dissolve, stirring occasionally.

- If you want to encourage a smooth, creamy texture: Store your honey in a cool pantry or cupboard (around 14°C or 57°F) to promote rapid, fine crystal formation.

Ultimately, crystallization is a characteristic of pure, natural honey—a process to be understood, not feared.

Summary Table:

| Factor | Influence on Crystallization | Key Details |

|---|---|---|

| Sugar Ratio (Glucose/Fructose) | Primary Driver | High glucose content (e.g., Clover, Rapeseed honey) accelerates crystallization. |

| Storage Temperature | Major Trigger | Ideal range: 10°C-18°C (50°F-65°F). Refrigeration speeds up the process. |

| Nucleation Sites | Catalyst | Pollen, beeswax, and air bubbles in raw honey provide surfaces for crystals to form. |

| Floral Source | Determines Sugar Ratio | Nectar type (e.g., Tupelo = slow; Clover = fast) dictates the honey's tendency to crystallize. |

Need High-Quality Beekeeping Supplies for Optimal Honey Production?

Understanding the science behind honey crystallization is key to producing a superior product. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the reliable tools needed to manage every stage of honey production, from harvest to storage.

We provide a comprehensive range of wholesale-focused beekeeping supplies and equipment—including storage containers, warming cabinets, and extraction tools—to help you maintain the perfect texture and quality for your honey.

Let's discuss your specific needs. Contact our expert team today to learn how our products can support your operation's efficiency and honey quality.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Natural Wood Honey Dipper for Tea Coffee and Desserts

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- 10L Stainless Steel Electric Honey Press Machine

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- Why is a laboratory benchtop refractometer essential for honey? Secure Stability & Quality

- What role does a high-precision refractometer play in honey moisture analysis? Ensure Honey Quality & Stability

- How is a manual refractometer used to determine honey quality? Essential Moisture Control for Commercial Beekeeping

- Why is a refractometer necessary for determining the moisture content and quality grade of honey? Ensure Market Success

- Why is a high-precision refractometer considered essential for honey quality? Master Moisture Control for Stability