When choosing a honey packaging machine, your decision must be guided by three primary factors: your required production volume, the specific type of container you use, and the viscosity of your honey. These elements determine whether you need a simple semi-automatic filler for a small operation or a fully integrated, automated line for large-scale production.

The goal is not to find the "best" machine, but the one that represents the right long-term investment for your specific business. This means carefully balancing the immediate need for speed and efficiency with the crucial factors of versatility, ease of cleaning, and overall cost-effectiveness.

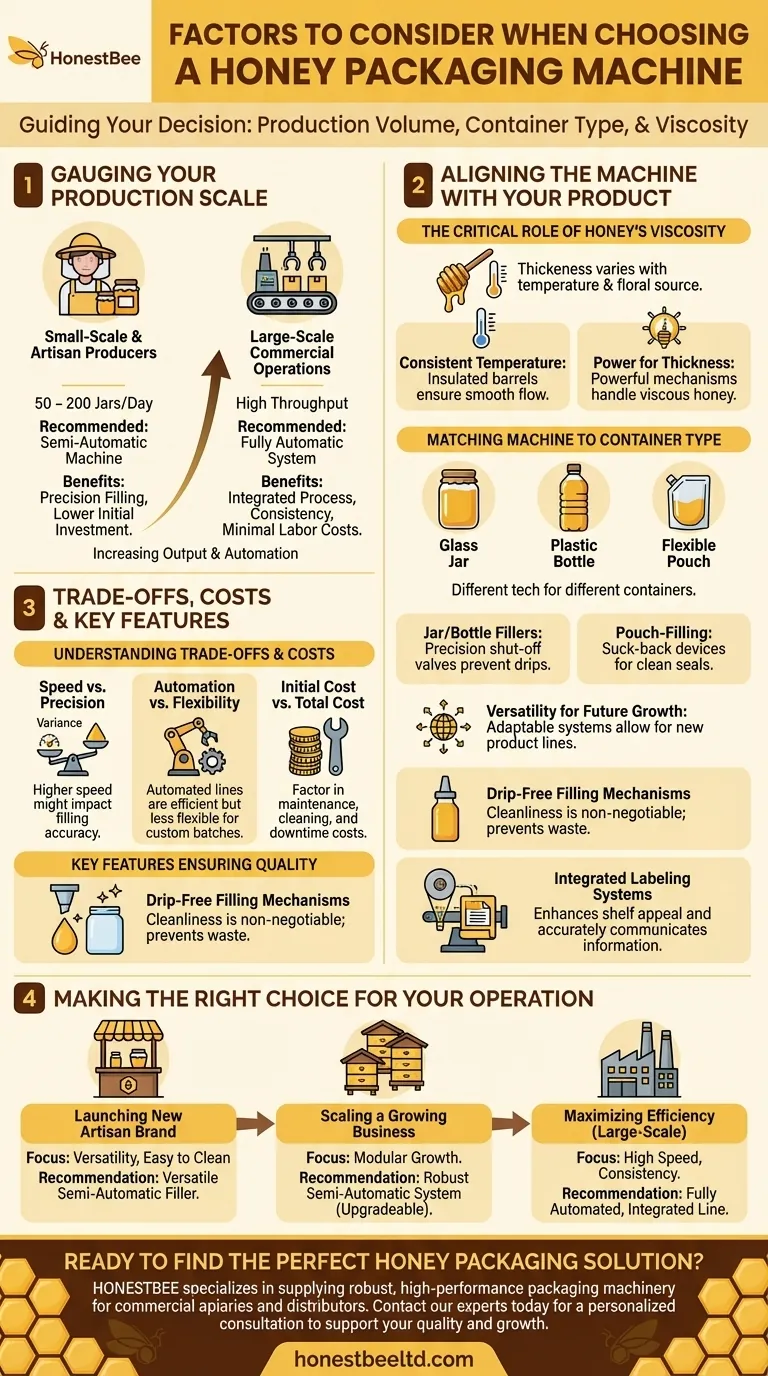

Foundational Decision: Gauging Your Production Scale

The first and most important consideration is your output. The number of units you need to package per day directly dictates the level of automation required.

For Small-Scale & Artisan Producers

If your operation is small-scale, filling between 50 and 200 jars per day, a semi-automatic machine is often the most practical choice. These systems offer precision filling without the significant capital investment of a fully automated line.

For Large-Scale Commercial Operations

For large producers, a fully automatic system is essential. These machines integrate filling, capping, and labeling into a continuous process, ensuring high throughput, consistency, and minimal labor costs.

Aligning the Machine with Your Product

Once you've determined your scale, you must match the machine's capabilities to your specific honey and the packaging you've chosen to represent your brand.

The Critical Role of Honey's Viscosity

Honey's thickness, or viscosity, changes with temperature and floral source. A suitable machine must handle this variability.

Some machines feature double-layer insulated barrels to maintain a consistent temperature, ensuring honey flows smoothly and its purity is preserved. The filling mechanism must be powerful enough to handle thick, viscous honey without strain.

Matching Machine to Container Type

The type of container you use—be it classic queenline glass jars, plastic bottles, or flexible pouches—fundamentally changes the required technology.

Jar and bottle fillers use precise shut-off valves at the nozzle to prevent overfilling and messy drips. Pouch-filling machines often incorporate a suck-back device to ensure a clean seal and prevent leakage.

Versatility for Future Growth

Consider whether a machine can adapt to different container sizes and shapes. A versatile system allows you to introduce new product lines without needing to invest in entirely new equipment, providing crucial flexibility as your business evolves.

Understanding the Trade-offs and Long-Term Costs

A packaging machine is a significant investment, and the sticker price is only part of the equation. Understanding the inherent trade-offs is key to making a wise decision.

Speed vs. Precision

While higher speed increases output, it can sometimes come at the cost of filling accuracy. You must decide on an acceptable level of variance. For a premium product, consistent, precise fills are paramount to maintaining brand trust.

Automation vs. Flexibility

Fully automated lines are incredibly efficient for a single, high-volume product. However, they can be less flexible and more time-consuming to change over for small, custom batches compared to semi-automatic systems.

Initial Cost vs. Total Cost of Ownership

The cheapest machine is not always the most cost-effective. Factor in the long-term expenses of maintenance, cleaning, and potential downtime. A machine that is easy to disassemble and clean saves significant labor time and helps ensure product hygiene.

Key Features That Ensure Product Quality

Beyond the core specifications, certain features directly impact the final quality and appeal of your product.

Drip-Free Filling Mechanisms

Cleanliness is non-negotiable. Features like precision shut-off valves and suck-back devices prevent product waste and ensure every container is clean, professional, and ready for sale.

Integrated Labeling Systems

A dedicated labeling machine integrated into the line ensures every label is applied accurately and consistently. This enhances shelf appeal and communicates vital product information clearly to the customer.

Making the Right Choice for Your Operation

To select the ideal honey packaging machine, align your choice with your primary business objective.

- If your primary focus is launching a new artisan brand: Prioritize a versatile semi-automatic filler that is easy to clean and can adapt to various jar sizes without a large initial investment.

- If your primary focus is scaling a growing business: Look for a robust semi-automatic system that can be integrated with a conveyor and other components later, allowing for modular growth.

- If your primary focus is maximizing efficiency in a large-scale operation: Invest in a fully automated, integrated line designed for high speed, unwavering consistency, and minimal downtime.

Choosing the right equipment is a strategic decision that will support your business's quality standards and growth for years to come.

Summary Table:

| Factor | Small-Scale / Artisan | Large-Scale Commercial |

|---|---|---|

| Production Volume | 50 - 200 jars/day | High throughput, automated lines |

| Recommended Machine | Semi-automatic filler | Fully automatic, integrated system |

| Key Considerations | Low initial investment, versatility, ease of cleaning | High speed, consistency, minimal labor costs |

Ready to find the perfect honey packaging solution for your operation?

HONESTBEE specializes in supplying commercial apiaries and beekeeping equipment distributors with the robust, high-performance packaging machinery they need to scale efficiently. Whether you require a precise semi-automatic filler for a growing brand or a fully integrated automated line for maximum output, our wholesale-focused operations ensure you get the right equipment at a competitive price.

Contact our experts today for a personalized consultation and discover how we can support your quality standards and business growth.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

People Also Ask

- What value do automatic honey-filling machines offer? Scaling Commercial Honey Production with Precision

- What is the significance of automated filling and labeling systems in honey quality? Build Consumer Trust with Precision

- Why is the integration of automated honey-filling machines necessary? Scale Your Commercial Honey Production Line

- How does automated honey sampling and filling equipment assist in safety evaluations? Ensure Lab-Grade Data Integrity

- How do industrial honey filling machines address the production challenges associated with high-yield honeybee colonies?