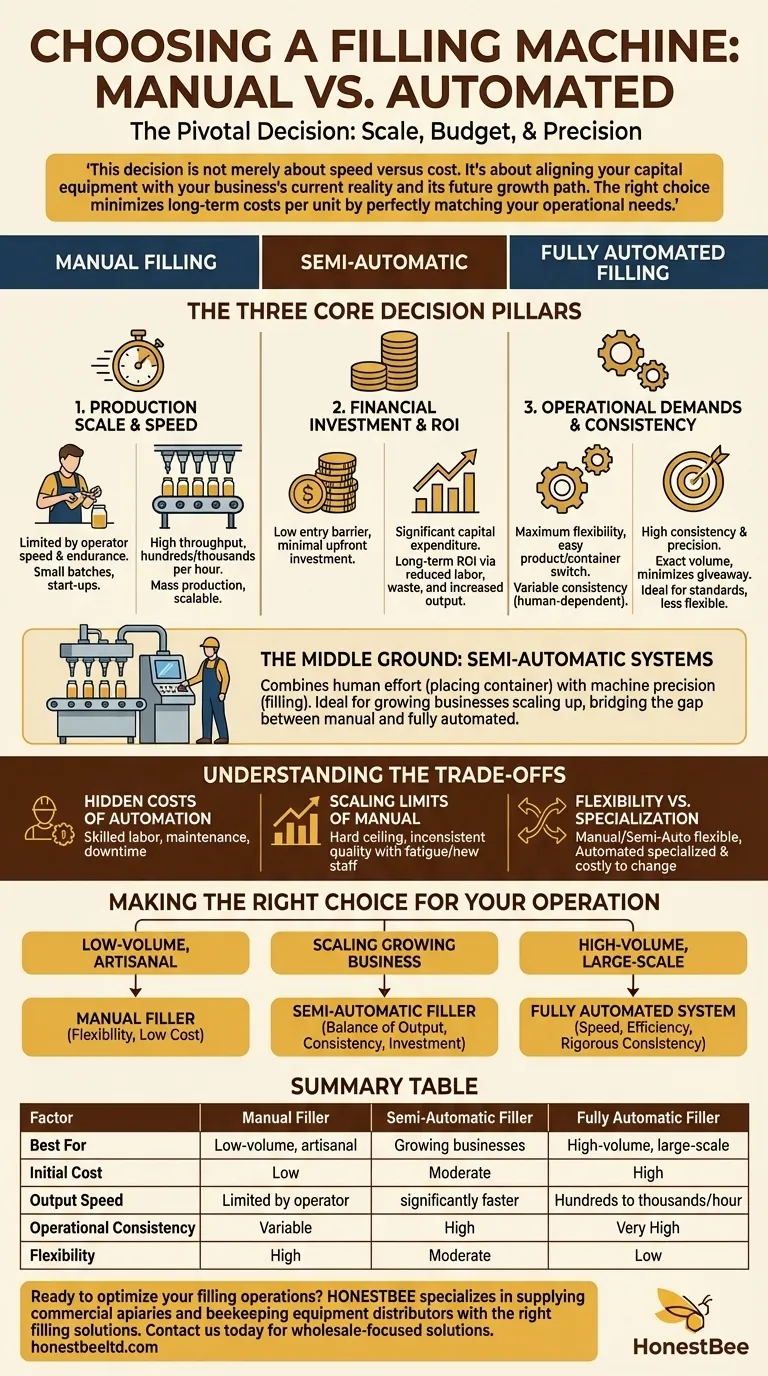

The choice between automated and manual filling machines is a pivotal decision that hinges on three primary factors: your scale of production, your budget, and your need for operational precision. While manual machines offer a low-cost entry point, automated systems provide the speed and consistency required for large-scale operations. Understanding where your business falls on this spectrum is the key to a sound investment.

This decision is not merely about speed versus cost. It's about aligning your capital equipment with your business's current reality and its future growth path. The right choice minimizes long-term costs per unit by perfectly matching your operational needs.

The Three Core Decision Pillars

To make an informed decision, you must evaluate your needs across three fundamental areas. Each pillar represents a critical aspect of your production environment and financial strategy.

1. Production Scale and Speed

The most significant differentiator is raw output. Manual filling is entirely limited by the speed and endurance of a human operator. This makes it suitable for small batches or start-up operations.

Automated filling machines are engineered for high throughput. They can fill hundreds or even thousands of containers per hour, operating continuously with minimal fatigue, making them essential for mass production. This inherent speed directly impacts your ability to scale and meet rising demand.

2. Financial Investment and ROI

The initial capital outlay varies dramatically. Manual fillers have a very low barrier to entry, requiring minimal upfront investment.

Automated systems represent a significant capital expenditure. However, this cost must be evaluated in the context of Return on Investment (ROI). The reduction in labor costs, minimized product waste due to high accuracy, and increased output can lead to a lower cost-per-unit in the long run.

3. Operational Demands and Consistency

Your product and brand standards dictate your operational needs. Manual filling offers maximum flexibility; an operator can switch between different products or container sizes with virtually no setup time.

Automated filling excels at consistency and precision. A machine dispenses the exact same volume every single time, which is critical for reducing product giveaway and maintaining quality standards. This removes the variable of human error.

The Middle Ground: Semi-Automatic Systems

For many growing businesses, the choice isn't a binary between manual and fully automatic. A third category provides a crucial stepping stone.

What is a Semi-Automatic Filler?

A semi-automatic machine combines human and machine effort. Typically, an operator places the container, and the machine performs the precise filling action, often triggered by a footswitch or button.

Bridging the Gap in Cost and Output

This approach offers a significant speed and consistency boost over purely manual methods without the full cost and complexity of a fully automated line. It is the ideal solution for businesses that have outgrown manual filling but are not yet ready for a six-figure investment.

Understanding the Trade-offs

Choosing a system requires an honest assessment of not just the benefits, but also the potential downsides of each approach.

The Hidden Costs of Automation

Fully automated lines are not "set it and forget it." They require skilled operators, a regular maintenance schedule, and potential downtime for repairs or product changeovers. These operational costs must be factored into your financial planning.

The Scaling Limits of Manual Filling

While cheap to start, manual filling has a hard ceiling. Relying solely on labor makes it difficult to respond to sudden demand spikes, and quality can become inconsistent as workers fatigue or as you add new, less-experienced staff.

Flexibility vs. Specialization

Manual and semi-automatic systems are highly flexible, easily adapting to new products. Many automated systems are specialized for a specific container type or product viscosity to maximize efficiency. Significant changes can require costly new parts and extensive setup time.

Making the Right Choice for Your Operation

Your decision should be a direct reflection of your business goals. Use these guidelines to determine the best path forward for your specific needs.

- If your primary focus is low-volume, custom, or artisanal production: A manual filler is your best choice for its unparalleled flexibility and minimal initial cost.

- If your primary focus is scaling a growing business: A semi-automatic machine provides the most effective balance of increased output, improved consistency, and manageable investment.

- If your primary focus is high-volume, large-scale manufacturing: A fully automated system is the only path to achieving the speed, long-term cost efficiency, and rigorous consistency required.

Aligning your equipment with your operational reality ensures your investment becomes a driver of growth, not a constraint.

Summary Table:

| Factor | Manual Filler | Semi-Automatic Filler | Fully Automatic Filler |

|---|---|---|---|

| Best For | Low-volume, artisanal production | Growing businesses scaling up | High-volume, large-scale manufacturing |

| Initial Cost | Low | Moderate | High |

| Output Speed | Limited by operator | Significantly faster than manual | Hundreds to thousands per hour |

| Operational Consistency | Variable (human-dependent) | High (machine-assisted) | Very High (fully automated) |

| Flexibility | High (easy product/container change) | Moderate | Low (specialized for efficiency) |

Ready to optimize your filling operations? HONESTBEE specializes in supplying commercial apiaries and beekeeping equipment distributors with the right filling solutions. Whether you need a manual, semi-automatic, or fully automated system, we provide high-quality, durable equipment designed for beekeeping's unique demands. Contact us today to discuss your needs and discover how our wholesale-focused solutions can enhance your productivity and profitability.

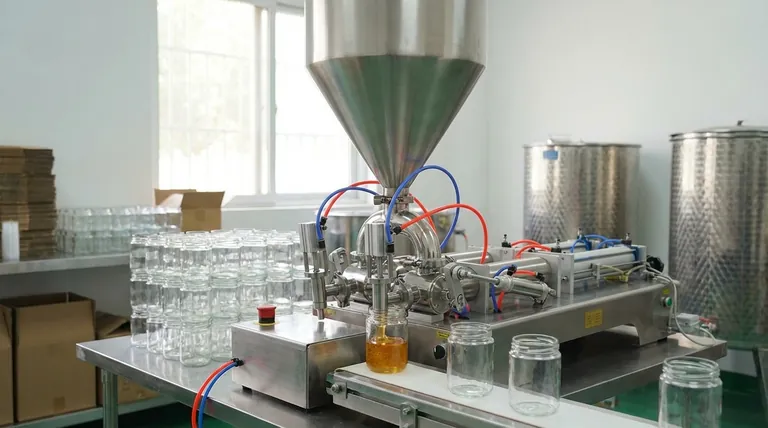

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Semi Automatic Round Bottle Labeling Machine

- Professional Durable Customizable Blister Packing Machine

- Professional Thermostatic Conical Honey Melter

People Also Ask

- How do industrial-grade honey-filling machines contribute to the market value of honey? Unlock Premium Brand Potential

- What are the technical advantages of using automated honey filling machinery? Boost Precision and Hygiene

- What role does an industrial honey-filling machine play in commercialization? The Key to Scalable Honey Production

- What are the different types of honey filling machines? Choose the Right Equipment for Your Apiary

- How do automated honey filling machines meet modern market trends? Elevate Your Brand with Precision and Safety

- What are the advantages of using automatic honey filling machines? Maintain Purity and Bioactivity in Commercial Honey

- How does the implementation of industrial honey filling machinery affect commercial apiaries? Boost Your Efficiency

- What role does automated honey-filling machinery play in preventing contamination? Ensure Pure, Safe Honey Production