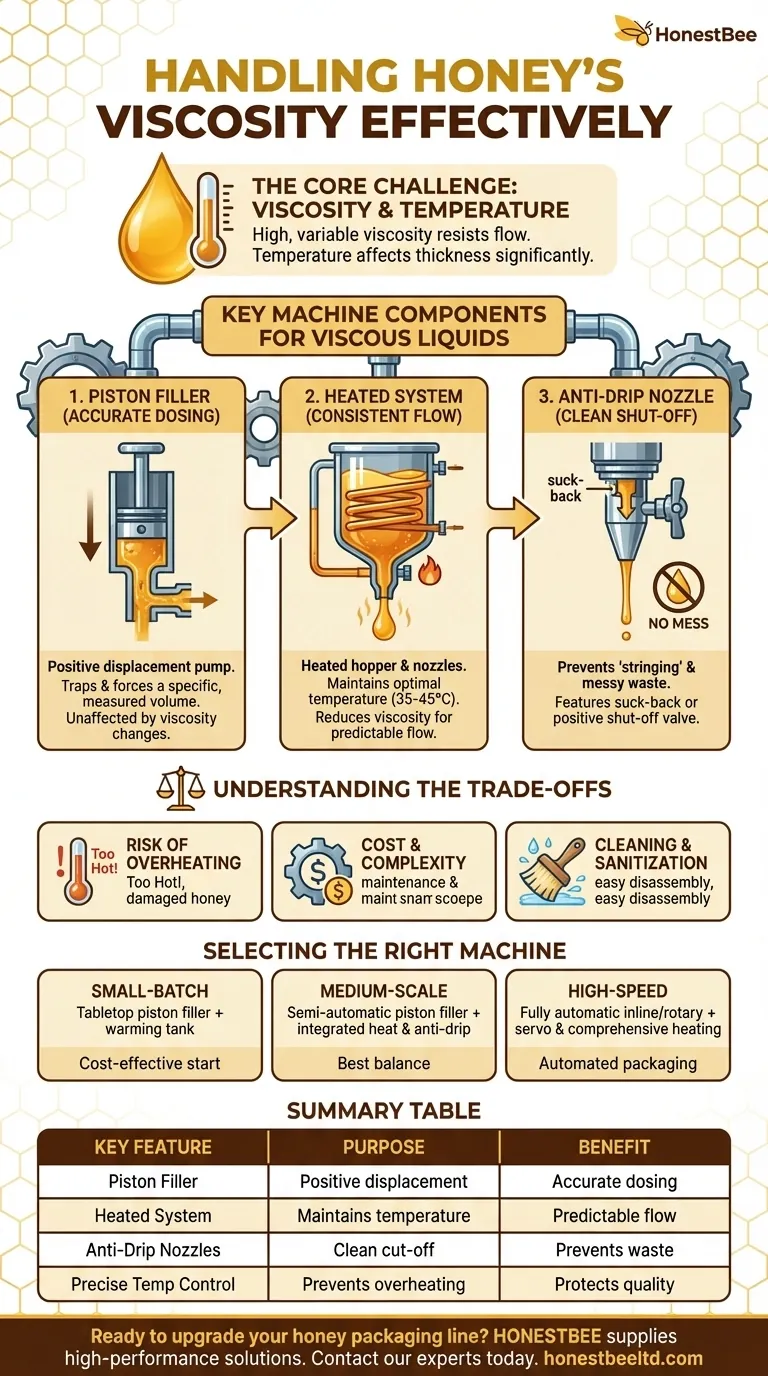

To handle honey effectively, a machine must overcome its high and variable viscosity. The essential features are a positive displacement pump like a piston filler for accurate dosing, a heating system for the tank and nozzles to ensure consistent flow, and specialized anti-drip nozzles to prevent messy product waste.

The core challenge with honey isn't just moving it, but moving it accurately and cleanly at a consistent speed. The solution lies in a system that combines powerful, precise pumping with meticulous temperature control to make the honey flow predictably.

The Core Challenge: Honey's Viscosity

Honey is a difficult product to package because its physical properties change dramatically based on its environment and composition. Understanding this is the first step to selecting the right equipment.

Why Viscosity Matters

Viscosity is a liquid's resistance to flow. Honey has a very high viscosity, meaning it flows slowly and requires significant force to move through pipes and nozzles.

This thickness makes it difficult for standard liquid fillers (like gravity fillers) to work, as they rely on the product flowing easily on its own. It can lead to slow production rates and inaccurate fill volumes.

The Critical Role of Temperature

Honey's viscosity is not constant; it is highly dependent on temperature. Gently warming honey dramatically reduces its viscosity, making it flow much more easily.

A machine that can maintain a consistent, elevated temperature is essential for achieving a predictable and efficient filling process. Without it, fill times and accuracy will fluctuate as the ambient temperature changes.

Key Machine Components for Viscous Liquids

A successful honey filling machine is a system of components working together. Each part is designed to solve a specific problem posed by the product's viscosity.

The Pumping Mechanism: Piston Fillers

The heart of any honey filler is the pump. A piston filler is the industry standard for a reason. It is a type of positive displacement pump.

This means it traps a specific, measured volume of honey in a cylinder and then forces it out. This method is exceptionally accurate and is not affected by changes in product viscosity, ensuring each container gets the correct amount.

Temperature Control: Heated Systems

To manage viscosity, heating is non-negotiable. An effective machine will have a heated, jacketed hopper or tank to warm the bulk honey to a target temperature.

Furthermore, heated filling nozzles and sometimes even heated hoses are used to ensure the honey remains at its optimal, lower-viscosity temperature right up to the point of dispense.

The Nozzle: Anti-Drip and Shut-Off Features

Because honey is so thick and sticky, it tends to "string" or drip after a fill cycle is complete, creating a mess and wasting product.

To prevent this, machines use anti-drip nozzles. These often feature a "suck-back" capability that pulls a small amount of product back into the nozzle after dispensing or a positive shut-off valve that cleanly cuts the flow.

Understanding the Trade-offs

While these features are highly effective, they come with operational considerations that you must balance against your production needs.

The Risk of Overheating

Heat is beneficial, but excessive heat can damage honey. Overheating can destroy its delicate enzymes, alter its flavor profile, and darken its color.

A quality machine must have precise, reliable temperature controls (thermostats) to hold the honey at the ideal temperature (typically 35-45°C or 95-115°F) without overshooting.

Cost and Complexity

Features like jacketed tanks, precision pumps, and advanced nozzles add to the machine's initial cost and mechanical complexity.

This also means there are more components to maintain and service over the life of the equipment.

Cleaning and Sanitization

Systems with integrated heating and complex pump assemblies can be more challenging to clean thoroughly. Easy disassembly for cleaning is a critical feature to look for, as improper cleaning can lead to product contamination.

Selecting the Right Machine for Your Operation

Your production scale and goals will determine the ideal combination of features.

- If your primary focus is small-batch, artisan production: A simple tabletop piston filler paired with a separate warming tank for pre-heating the honey is a cost-effective start.

- If your primary focus is consistent, medium-scale production: A semi-automatic piston filler with an integrated heated hopper and anti-drip nozzles offers the best balance of efficiency, accuracy, and control.

- If your primary focus is high-speed, automated packaging: You require a fully automatic inline or rotary filling system with servo-driven pumps, comprehensive heating throughout, and sophisticated nozzle controls.

Choosing the right machinery means investing in a system that maintains the quality of your honey while delivering the accuracy and cleanliness your operation requires.

Summary Table:

| Key Feature | Purpose | Benefit |

|---|---|---|

| Piston Filler | Positive displacement pumping | Accurate dosing regardless of viscosity changes |

| Heated Hopper & Nozzles | Maintains consistent product temperature | Reduces viscosity for predictable, fast flow |

| Anti-Drip Nozzles | Cleanly cuts off product flow | Prevents waste and messy packaging |

| Precise Temperature Control | Prevents overheating | Protects honey quality (flavor, color, enzymes) |

Ready to upgrade your honey packaging line? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-performance, wholesale-focused filling solutions. Our machines are engineered to handle honey's unique challenges, ensuring precise fills, zero waste, and protected product quality. Contact our experts today to find the perfect system for your production scale.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- What role does constant temperature oscillation equipment play in the extraction of bee pollen? Boost Kinetic Yield

- What role does specialized processing machinery play in the development of a modern apiary workshop? Boost Scale and ROI

- What is done with the honey after extraction and filtering? From Purification to Perfect Packaging

- Why is the sterilization of industrial honey extraction and bottling machinery essential? Ensure Food Safety & Purity

- Why is industrial-grade stainless steel processing equipment required for honey harvesting? Ensure Purity & Compliance

- Why is a Pfund scale colorimeter required for the color classification of honey? Standardize Quality for Export

- How is titration equipment utilized to determine lactone and free acidity in honey? Master Precision Analysis

- What are the technical advantages of SFE over ethanol maceration? Elevate Propolis Extraction for Superior Purity