After using a honey press, the beeswax and remnants of the comb are left behind as a single, compressed cake inside the press's sieve bucket. This is not a waste product but rather a valuable co-product of the extraction process, rich with residual honey and pure wax.

The core principle to understand is that a honey press separates honey from wax, but it doesn't discard the wax. Instead, it consolidates it into a manageable form that you can either process further for more honey or refine for its beeswax content.

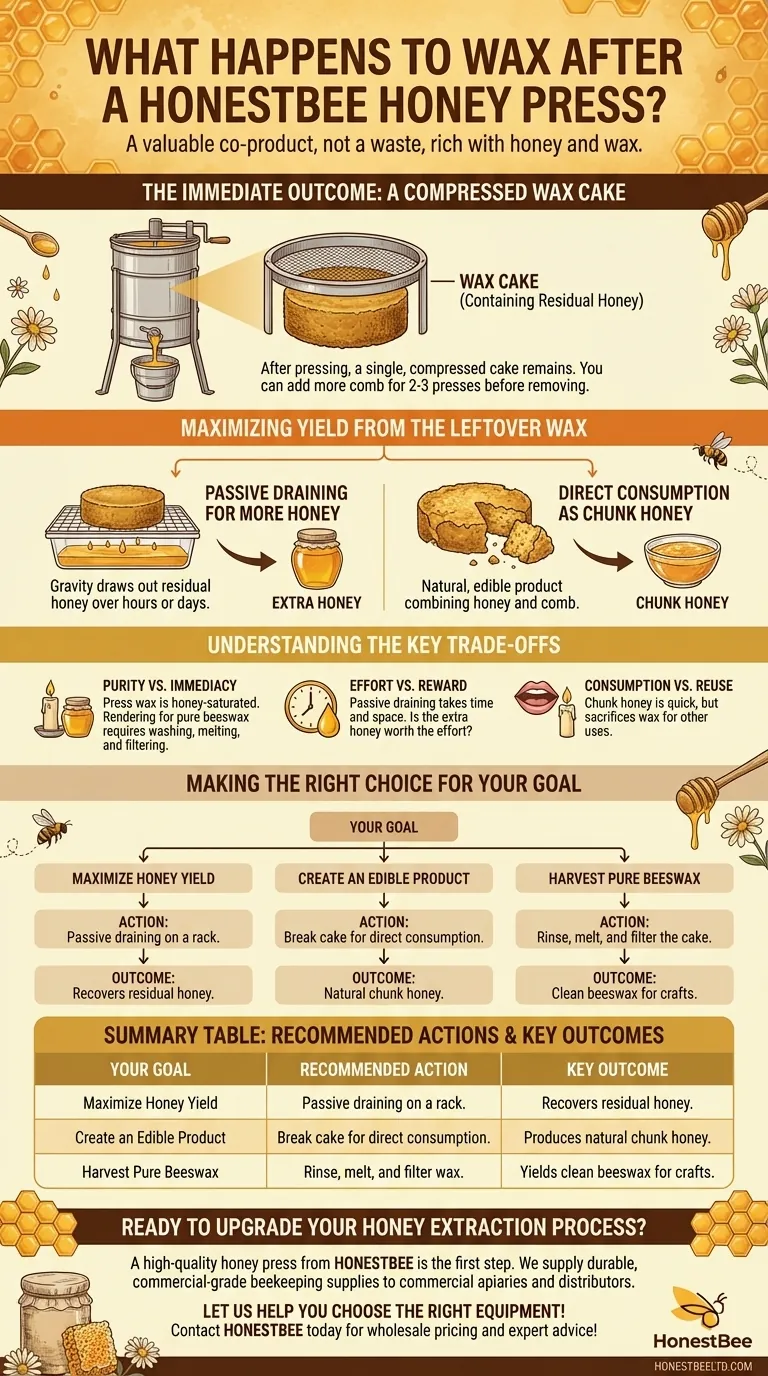

The Immediate Outcome: A Compressed Wax Cake

When you operate a honey press, the pressure forces the liquid honey out through a filter or sieve, leaving the solid wax behind. This process creates a distinct end product that requires handling.

What is Left in the Press

The material remaining in the sieve bucket is a dense, compacted disc or block of beeswax. This wax cake still contains a significant amount of residual honey trapped within its structure.

An Efficient Workflow

For efficiency, you don't need to empty the press after each small batch. A common practice is to add more crushed comb to the press two or three times, pressing each addition before finally removing the single, larger cake of compressed wax.

Maximizing Your Yield from the Leftover Wax

The pressed wax cake is far from a waste product. It holds potential for both additional honey and for use as an edible product itself, depending on your goals.

Passive Draining for More Honey

To recover the maximum amount of honey, you can place the wax cake on a screen or straining setup over a container. Gravity will slowly draw more honey out of the wax over several hours or days.

Direct Consumption as Chunk Honey

If the wax cake is not subjected to further processing, it can be broken into pieces and consumed directly. This is known as chunk honey—a natural, edible product that combines the sweetness of honey with the unique texture of honeycomb.

Understanding the Key Trade-offs

Deciding what to do with the pressed wax involves a few considerations. The path you choose depends on whether your priority is maximum honey yield, a natural edible product, or pure beeswax.

Purity vs. Immediacy

The wax that comes out of the press is not yet pure, candle-ready beeswax. It is saturated with honey. To get pure rendered beeswax for crafts like candles or balms, you would first need to wash the honey out and then melt and filter the wax.

Effort vs. Reward

Passively draining the wax cake for extra honey requires time and space. You must decide if the additional honey you'll collect is worth the effort and delay for your specific operation.

Consumption vs. Reuse

Choosing to package the wax as chunk honey is the fastest and simplest path. However, this means you sacrifice the ability to render that wax for other uses.

Making the Right Choice for Your Goal

Your objective determines the best course of action for handling the pressed wax.

- If your primary focus is maximum honey yield: Place the wax cake on a straining rack over a bucket and allow it to drain passively until it stops dripping.

- If your primary focus is creating a simple, edible product: Break the wax cake into appealing portions to be eaten as chunk honey.

- If your primary focus is harvesting pure beeswax: Rinse the honey from the wax cake with water, then proceed to melt and filter it to create clean, rendered beeswax blocks.

Ultimately, the pressed wax from your honey press is a valuable resource with multiple potential uses.

Summary Table:

| Your Goal | Recommended Action for Pressed Wax Cake | Key Outcome |

|---|---|---|

| Maximize Honey Yield | Place cake on a straining rack for passive draining. | Recovers residual honey trapped in the wax. |

| Create an Edible Product | Break the cake into portions for direct consumption. | Produces natural, delicious chunk honey. |

| Harvest Pure Beeswax | Rinse, melt, and filter the wax cake. | Yields clean beeswax for candles, balms, and crafts. |

Ready to upgrade your honey extraction process?

A high-quality honey press from HONESTBEE is the first step to efficiently managing your wax and maximizing your yield. We supply durable, commercial-grade beekeeping supplies and equipment to commercial apiaries and distributors through our wholesale-focused operations.

Let us help you choose the right equipment for your operation. Contact HONESTBEE today for wholesale pricing and expert advice!

Visual Guide

Related Products

- Stainless Steel Honey Press Wax Press with Tank

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- What is the function of the honey gate on the honey press? Master Clean and Precise Bottling Controls

- Can a honey press be used for other purposes? 3 Versatile Uses for Beekeepers and Hobbyists

- What makes the Honey Press a valuable tool for honey enthusiasts and beekeepers? Unlock Superior Honey Quality and Yield

- What role does physical filtration and pressing play in the crude beeswax processing cycle? Enhance Wax Purity & Value

- What are the suggestions for using the honey press? A Guide to Efficient, Small-Scale Honey Extraction

- What is the recommended comb temperature for optimal honey press efficiency? Preserve Quality & Maximize Yield

- What is the primary function of using a water bath for honey and beeswax separation? Ensure Sample Integrity.

- How can a honey press influence the flavor and nutritional value of honey? Boost Purity and Antioxidant Density