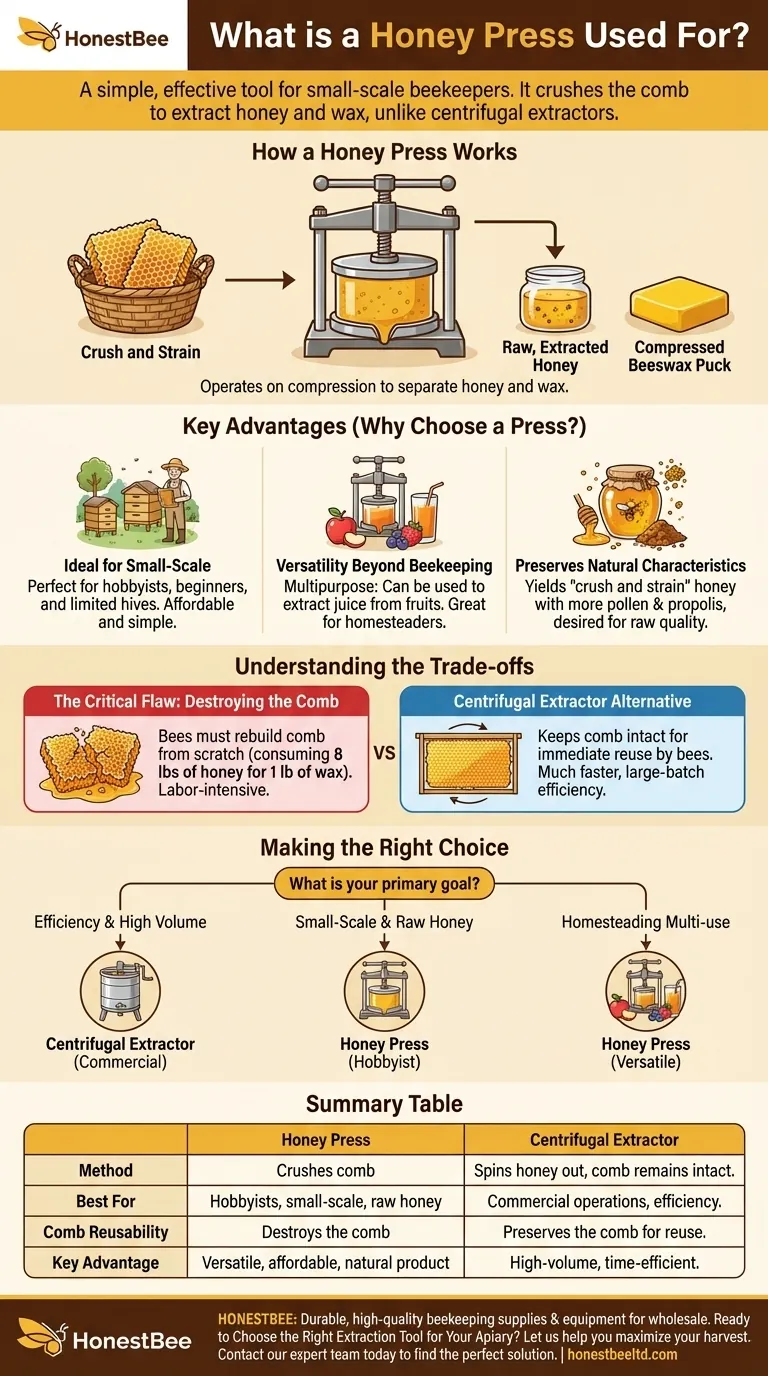

At its core, a honey press is a mechanical device used to extract honey from raw honeycomb. Unlike centrifugal extractors that spin honey out, a press works by applying immense pressure to crush the comb, forcing the honey out and separating it from the beeswax.

A honey press is a simple, effective tool for small-scale beekeepers who prioritize versatility and a more natural extraction method. However, its use comes with a critical trade-off: it destroys the honeycomb in the process.

How a Honey Press Works

A honey press, sometimes called a comb crusher, operates on the simple principle of compression. It provides a low-tech but effective way to separate honey and wax.

The Basic Principle: Crush and Strain

The process involves placing pieces of raw honeycomb, often pre-crushed for better efficiency, into a slatted or perforated basket inside the press. A pressure plate is then screwed down, squeezing the comb and forcing the liquid honey to flow out through the openings, where it is collected below.

The End Products: Honey and Wax

This method yields two distinct products. The first is the raw, extracted honey. The second is a compressed puck of clean, pure beeswax, which can then be rendered and used for candles, cosmetics, or other projects.

Best Practices for Operation

For optimal results, it is recommended to bolt the press to a stable surface. Oiling the screw mechanism with a food-grade lubricant ensures smooth operation. After extraction, the press should be cleaned thoroughly with warm water and a soft brush to prevent buildup.

Why Choose a Honey Press? Key Advantages

While not as common as centrifugal extractors, honey presses offer distinct benefits that make them the right choice for certain beekeepers and specific goals.

Ideal for Small-Scale Operations

Honey presses are perfectly suited for hobbyists, beginners, or those with only a few hives. Their relatively small size, reasonable price, and simplicity make them an accessible entry point into honey extraction without a large investment.

Versatility Beyond Beekeeping

A significant advantage is its multipurpose nature. The same press can be used to extract juice from fruits and berries, making it a valuable tool for homesteaders or winemakers. This versatility can justify the investment for those with diverse agricultural interests.

Preserving Natural Honey Characteristics

Many proponents of the press method believe it better preserves the natural qualities of the honey. This "crush and strain" honey often contains more pollen and propolis, which is highly desired by consumers seeking raw, minimally processed honey.

Understanding the Trade-offs: The True Cost

The primary reason honey presses are not the standard for commercial operations is due to a few significant drawbacks. Understanding these trade-offs is crucial.

The Critical Flaw: Destroying the Comb

The most significant trade-off is that a press destroys the drawn-out honeycomb. Bees expend a tremendous amount of energy and resources (consuming about 8 pounds of honey to produce 1 pound of wax) to build this comb.

A centrifugal extractor, by contrast, keeps the comb intact, allowing it to be returned to the hive. This enables the bees to immediately start refilling it with honey instead of spending weeks rebuilding it from scratch.

The Labor and Time Investment

Using a honey press is a manual, labor-intensive, and time-consuming process. It involves cutting comb from frames, crushing it, loading the press in batches, and cleaning up. This is far slower than the large-batch efficiency of a centrifugal extractor.

Making the Right Choice for Your Operation

Choosing between a press and an extractor depends entirely on your scale, philosophy, and goals.

- If your primary focus is efficiency and honey volume: A centrifugal extractor is the superior choice, as preserving the comb dramatically increases your bees' productivity.

- If you are a hobbyist with one or two hives: A honey press is an affordable and straightforward tool for processing small harvests.

- If your goal is producing raw, minimally processed honey: The crush and strain method from a press yields a product that many consumers specifically seek out.

- If you are a homesteader seeking a multi-use tool: The press's ability to also process fruit makes it a highly practical and valuable investment.

Ultimately, the right tool is the one that aligns with your specific beekeeping philosophy and operational needs.

Summary Table:

| Aspect | Honey Press | Centrifugal Extractor |

|---|---|---|

| Method | Crushes comb with pressure | Spins honey out, comb remains intact |

| Best For | Hobbyists, small-scale, raw honey | Commercial operations, efficiency |

| Comb Reusability | Destroys the comb | Preserves the comb for reuse |

| Key Advantage | Versatile, affordable, natural product | High-volume, time-efficient |

Ready to Choose the Right Extraction Tool for Your Apiary?

Whether you're a commercial beekeeper prioritizing efficiency or a hobbyist seeking a natural product, having the right equipment is key to your success. HONESTBEE supplies durable, high-quality beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors through our wholesale-focused operations.

Let us help you maximize your harvest. Contact our expert team today to discuss your specific needs and find the perfect extraction solution for your operation.

Visual Guide

Related Products

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

People Also Ask

- What is the pressing method of honey? Preserve Flavor & Quality with Traditional Extraction

- What are the specific applications for a comb crusher in beekeeping? Efficient Recovery for Foundationless Hives

- What are the advantages of the crush and strain method? A Low-Cost Start for New Beekeepers

- In what scenarios is a Honey Presser used? Essential Recovery & Processing Solutions for Modern Apiaries

- What role do plant-fiber woven baskets or pressing equipment play in honey extraction? Enhance Purity & Efficiency

- How does the honey screw press operate? A Guide to Maximizing Honey Yield from Cappings

- What are the available processing capacities for the honey-wax separating screw press? Boost Your Production Efficiency

- What are the potential drawbacks of honey produced using a honey press? Navigate Quality & Market Challenges