Processing honey is a systematic method of separating pure honey from the beeswax and other debris found within the hive. In essence, the process involves three key stages: removing the honey from the sealed honeycomb, filtering out any impurities, and finally, bottling the finished product for storage and consumption. The specific tools and techniques you need depend directly on the scale of your operation.

The fundamental goal of honey processing is not to alter the honey, but to carefully separate it from the wax comb and hive debris. The equipment required ranges from simple kitchen utensils for a single hive to specialized machinery for a commercial business, all designed to achieve this separation while preserving the honey's natural quality.

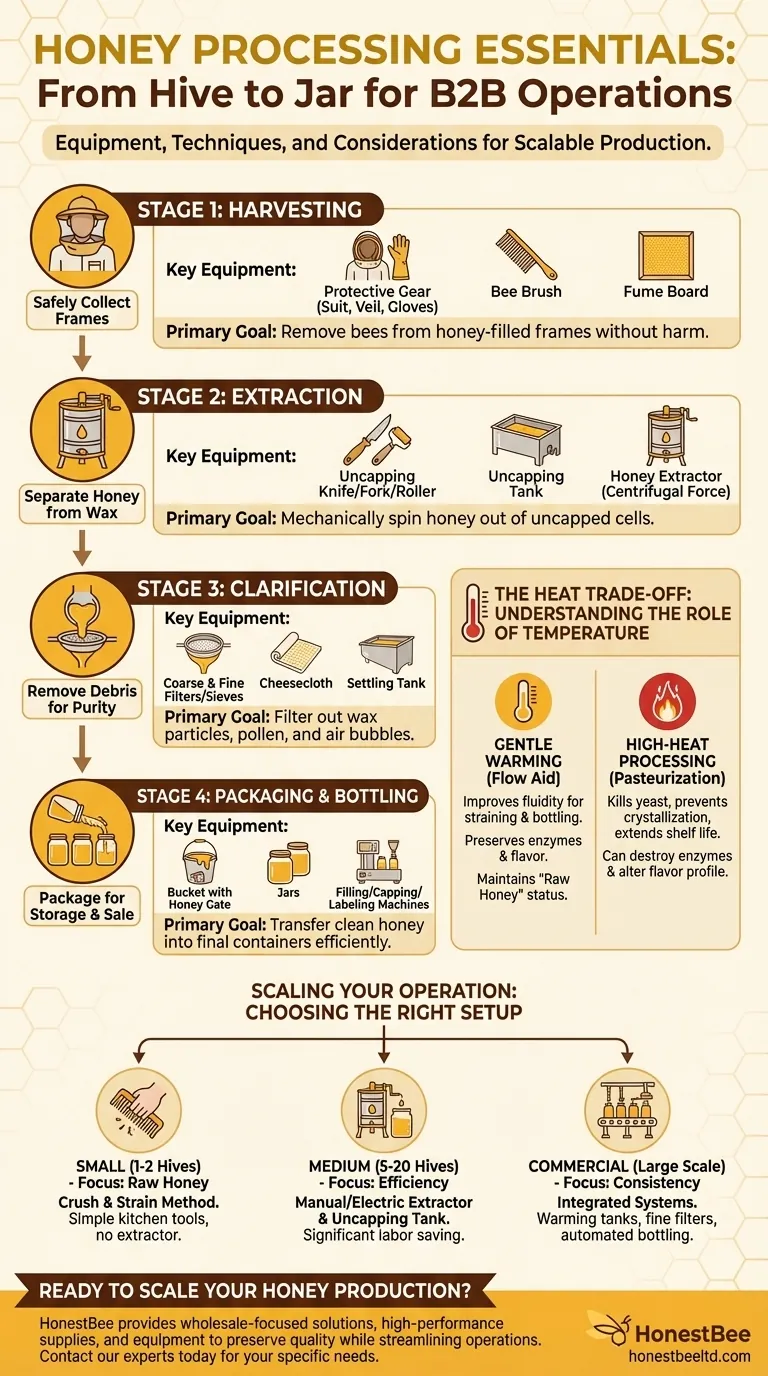

The Core Stages of Honey Processing

The journey from a full honeycomb to a jar of pure honey can be broken down into a few distinct stages. Each step has a specific purpose and requires particular tools.

Stage 1: Harvesting from the Hive

Before any processing can begin, you must collect the honey-filled frames from the hive. This requires safely encouraging the bees to leave the honeycombs.

Your essential equipment for this stage includes protective gear (a bee suit, veil, and gloves) and a tool to clear the bees. Common options include a simple bee brush to gently sweep bees off the frames or a fume board, which uses a non-toxic repellent to drive them away.

Stage 2: Extraction (Separating Honey from Wax)

Once you have the frames, the goal is to get the honey out of the sealed wax cells. This is the most labor-intensive part of the process.

First, you must uncap the honeycomb. Beekeepers use a sharp uncapping knife (which can be heated or cold), a specialized uncapping fork, or a spiked roller to slice or puncture the wax cappings that seal each cell. The removed cappings and initial honey drips are collected in an uncapping tank or a food-grade bucket.

Next, the uncapped frames are placed in a honey extractor. This device uses centrifugal force, spinning the frames at high speed to sling the honey out against the walls of the drum, where it flows down to a collection point at the bottom.

Stage 3: Clarification (Straining and Settling)

The honey collected from the extractor will contain bits of beeswax, pollen, and other small particles. The clarification stage is about creating a pure, clear final product.

This is primarily done through straining and filtration. The honey is typically poured through a series of sieves or filters with progressively finer mesh. A coarse filter will catch large pieces of wax, while a finer filter, like cheesecloth or a specialized honey filter, will remove smaller particles.

For many small-scale producers, simply letting the honey sit in a sealed container for several days—a process called settling—is enough. The lighter wax particles and air bubbles will rise to the top and can be skimmed off.

Stage 4: Packaging and Bottling

The final step is to transfer the clean, filtered honey into jars for storage.

Most processing buckets or tanks are equipped with a honey gate, which is a simple valve at the bottom that allows for controlled, mess-free filling of jars. For larger operations, automated filling machines, capping machines, and labelers streamline this process significantly.

Understanding the Trade-offs: The Role of Heat

You will often hear about heating honey during processing. This is a critical step to understand, as it presents a major trade-off between efficiency and the honey's natural quality.

Why Heat Is Sometimes Used

Honey is viscous, meaning it flows slowly. Gently warming honey (e.g., in a jacketed tank or water bath) dramatically improves its fluidity. This makes it much easier and faster to strain through fine filters and to bottle without introducing excessive air bubbles.

The "Raw Honey" Dilemma

The primary drawback of heating is its effect on the honey itself. Honey contains natural enzymes and delicate aromatic compounds. Heating honey above approximately 115°F (45°C) can begin to destroy these beneficial enzymes and alter its complex flavor profile. Honey that has not been heated above this temperature is often marketed as "raw honey."

Gentle Warming vs. High-Heat Processing

There is a significant difference between gently warming honey to aid flow and the high-temperature pasteurization used in large-scale commercial packing. The latter is designed to kill yeast cells and prevent crystallization for a longer shelf life but fundamentally changes the nature of the honey.

Making the Right Choice for Your Goal

The equipment you need is tied directly to your specific objective. There is no single "correct" setup; there is only the right setup for your scale and philosophy.

- If your primary focus is producing raw honey from one or two hives: You can start with the "crush and strain" method (crushing the comb by hand and straining it through cheesecloth) and avoid purchasing an extractor entirely.

- If your primary focus is efficiently processing honey from 5-20 hives: Investing in a small manual or electric extractor and a dedicated uncapping tank will save you significant time and labor.

- If your primary focus is creating a consistent, shelf-stable commercial product: You will need to consider integrated systems with gentle warming tanks for homogenization, fine filters, and bottling equipment to ensure efficiency and uniformity.

Ultimately, the right honey processing setup respects the natural character of the honey while meeting the scale of your ambition.

Summary Table:

| Processing Stage | Key Equipment Needed | Primary Goal |

|---|---|---|

| Harvesting | Bee suit, bee brush, fume board | Safely collect honey-filled frames from the hive. |

| Extraction | Uncapping knife/fork, extractor, uncapping tank | Separate honey from the wax comb using centrifugal force. |

| Clarification | Coarse & fine filters (e.g., cheesecloth), settling tank | Remove wax particles and debris for a pure, clear product. |

| Bottling | Bucket with honey gate, jars, labeling machine | Package the finished honey for storage and sale. |

Ready to Scale Your Honey Production?

Whether you're a commercial apiary aiming for maximum efficiency or a distributor sourcing reliable equipment, HONESTBEE has the wholesale-focused solutions you need. We supply durable, high-performance beekeeping supplies and processing equipment designed to preserve honey's natural quality while streamlining your operation.

Let us help you build the perfect processing setup. Contact our experts today to discuss your specific needs and volume requirements.

Visual Guide

Related Products

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

People Also Ask

- What are the advantages of professional honey collection equipment? Boost Yield & Quality for Commercial Beekeeping

- What is the role of specialized collection equipment for high-value bee products? Boost Purity and Profitability

- Why is it necessary to equip honey processing facilities with specialized filtration and dehydration equipment?

- What is the technical necessity of low-temperature pasteurization in bee patty production? Protect Hive Nutrition

- What principle does the honey vacuum thickener use to concentrate honey? Preserve Quality with Low-Temperature Evaporation

- Why is food-grade stainless steel critical in honey production? Ensure Purity and Compliance

- What factors should be considered when choosing honey packaging? Optimize for Brand, Operations & Market

- Why must stingless bee honey remain in Settling Containers for 30 to 45 days before bottling? Ensure Quality & Stability