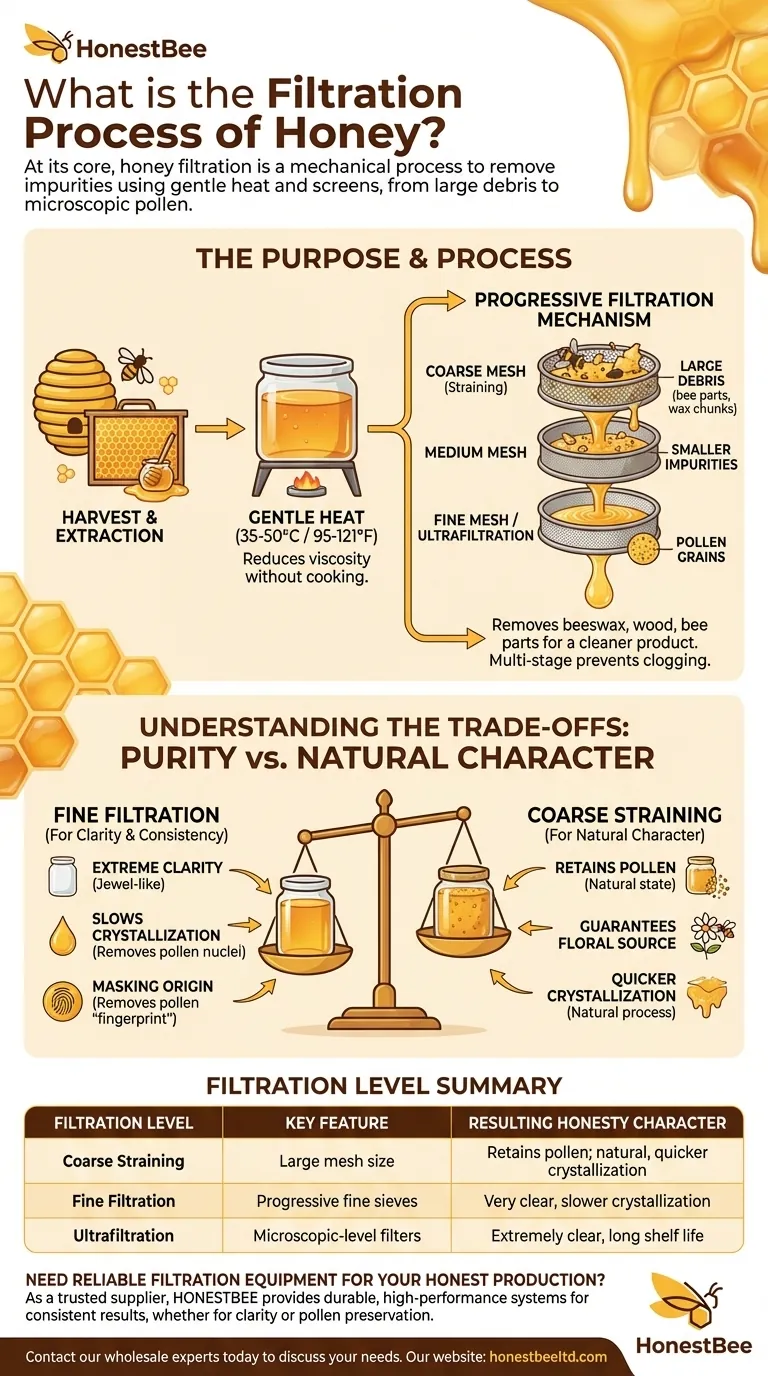

At its core, honey filtration is a mechanical process designed to remove physical impurities left over from the extraction process. Harvested honey is gently heated to reduce its viscosity and then passed through a series of progressively finer mesh screens or filters. This removes debris such as beeswax, wood splinters from the hive, and parts of bees, resulting in a cleaner, clearer final product.

The term "filtration" is not one-size-fits-all; it exists on a spectrum. The size of the filter's mesh determines what is removed, ranging from large hive debris to microscopic pollen grains, which fundamentally alters the honey's final character and properties.

The Purpose and Process of Honey Filtration

Honey straight from the hive contains more than just honey. The extraction process, which spins honey out of the comb, inevitably introduces small particles of wax, propolis, and other hive debris. Filtration is the standard industry step to create a clean, safe, and visually appealing product for the consumer.

The Role of Gentle Heat

Raw honey is extremely thick, or viscous. Pushing it through a filter in this state is slow and inefficient.

To solve this, processors gently heat the honey, typically to a range of 95-121°F (35-50°C). This isn't cooking; it's just enough to make the honey flow more easily without degrading its natural enzymes or flavor.

Straining vs. Filtering: A Critical Distinction

The first level of purification is often simple straining. This uses a coarse mesh to catch only the largest visible impurities, like bee wings or large wax particles.

Honey that has only been strained retains all of its natural pollen and is often what is sold as "raw" or "unfiltered" honey, though the terms can be used loosely.

The Filtration Mechanism: Progressive Sieves

True filtration goes a step further. Commercial operations use machines that force the honey through a series of progressively finer filters.

The honey might first pass through a coarse screen to remove large debris, then a medium screen, and finally a fine screen. This multi-stage process prevents the finest filter from clogging too quickly. Some high-volume systems also use pressure to speed up the process.

Understanding the Trade-offs

The level of filtration a honey undergoes is the most significant factor in the trade-off between purity and natural character. There is no single "best" method; it depends entirely on the desired outcome.

Fine Filtration: For Clarity and Consistency

Very fine filters, sometimes on a microscopic level (ultrafiltration), remove almost all suspended solids. This includes the tiny pollen grains that are naturally present in honey.

Producers may do this for several reasons:

- Extreme Clarity: It creates a brilliantly clear, jewel-like honey that many consumers find appealing.

- Slows Crystallization: Pollen grains act as nuclei for sugar crystals to form around. Removing them significantly delays the natural process of crystallization, keeping the honey liquid for longer on the shelf.

- Masking Origin: Pollen is the "fingerprint" that identifies a honey's floral and geographic source. Removing it can make the honey's origin untraceable.

Coarse Straining: For Natural Character

Using a larger mesh size (straining) is a deliberate choice to preserve the honey's natural state as much as possible.

This method ensures the pollen remains in the honey. Many consumers seek out honey with pollen for its potential health benefits and because it guarantees the honey's floral source and authenticity. The trade-off is a honey that may be less clear and will crystallize more quickly.

Making the Right Choice for Your Goal

Understanding the filtration process empowers you to choose the honey that best suits your needs, whether you are a consumer or a small-scale producer.

- If your primary focus is a long shelf life and perfect clarity: Choose a finely filtered honey. It will stay liquid longer and have a clean, uniform appearance.

- If your primary focus is preserving the natural character and floral source: Choose a honey that is "strained" or explicitly labeled "unfiltered." This ensures the pollen and its associated properties are retained, though it will crystallize naturally over time.

Ultimately, knowing what "filtration" means allows you to look past the label and understand the true nature of the honey in the jar.

Summary Table:

| Filtration Level | Key Feature | Removes | Resulting Honey Character |

|---|---|---|---|

| Coarse Straining | Large mesh size | Large debris (wax, bee parts) | Retains pollen; natural, quicker crystallization |

| Fine Filtration | Progressive fine sieves | Most solids, including pollen | Very clear, slower crystallization |

| Ultrafiltration | Microscopic-level filters | Nearly all suspended particles | Extremely clear, long shelf life |

Need Reliable Filtration Equipment for Your Honey Production?

As a trusted supplier to commercial apiaries and distributors, HONESTBEE provides the durable, high-performance filtration systems and supplies you need for efficient, large-scale honey processing. Whether your goal is crystal clarity or preserving natural pollen, our equipment delivers consistent results.

Contact our wholesale experts today to discuss your operation's specific needs and discover how we can support your business growth.

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Thermostatic Conical Honey Melter

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

People Also Ask

- What safety precautions should be taken when operating the honey vacuum thickener? Protect Your Apiary Investment

- How is the cooling system configured when using tap water in the honey vacuum thickener? A Simple Guide for Beekeepers

- What are the benefits of motorized honey extractors? Save Time & Labor in Your Apiary

- What are the benefits of a honey concentrator? Elevate Your Honey Quality and Market Value

- What additional functions does a honey vacuum thickener have? Achieve a Stable, Commercial-Grade Product