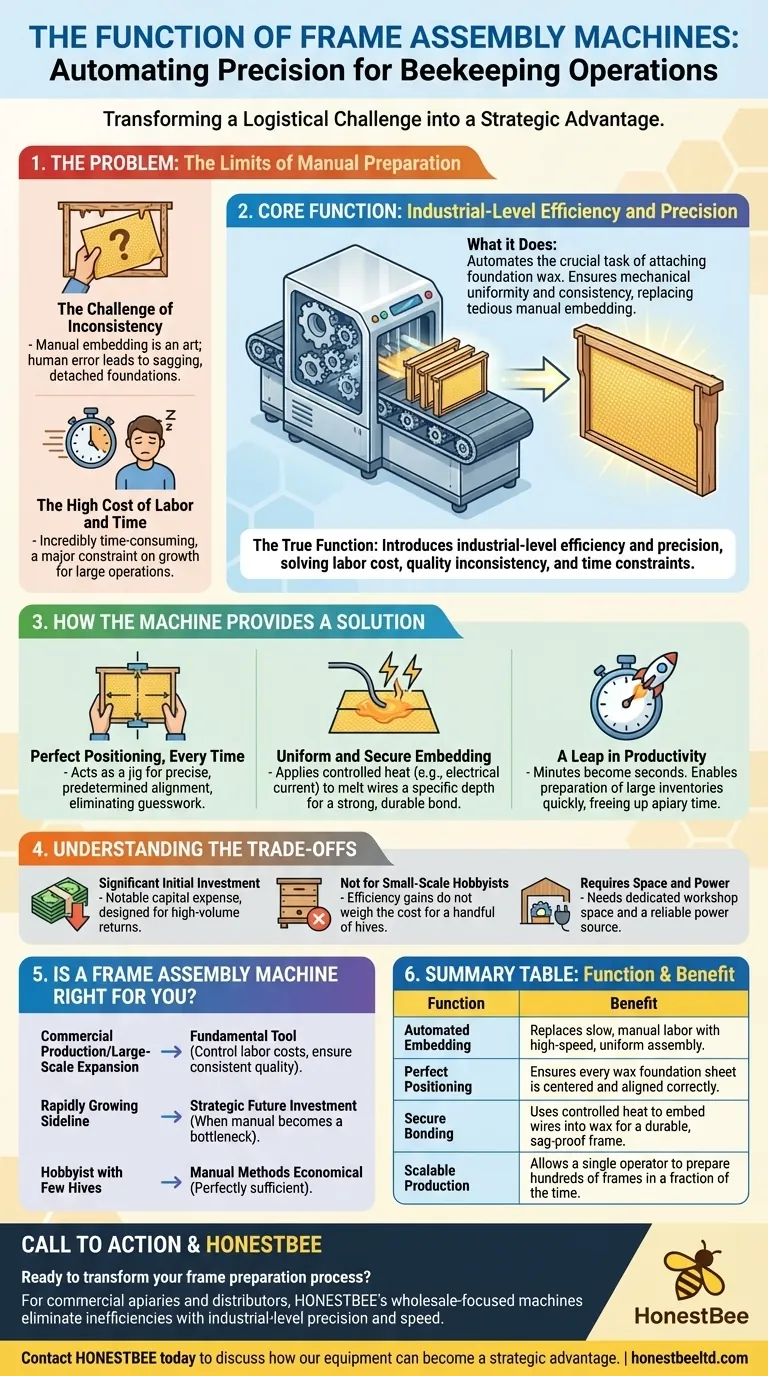

At its core, a frame assembly machine automates the crucial and repetitive task of attaching foundation wax to wooden hive frames. It is purpose-built to replace the tedious manual process of embedding, ensuring every sheet of foundation is positioned with mechanical uniformity and consistency.

The true function of a frame assembly machine is to introduce industrial-level efficiency and precision into beekeeping operations. It solves the core challenges of labor cost, inconsistent quality, and the time required to prepare a large number of frames for hive expansion or replacement.

The Problem: The Limits of Manual Preparation

Before understanding the machine, we must first appreciate the manual task it replaces. Preparing frames by hand is a bottleneck for any beekeeper looking to scale their operation.

The Challenge of Inconsistency

Manually embedding foundation wax into wired frames is an art. It requires carefully heating the wires and pressing the wax just right, a process where human error can easily lead to poorly secured foundation that may sag or detach within the hive.

The High Cost of Labor and Time

This manual process is incredibly time-consuming. For a commercial beekeeper who needs to prepare hundreds or thousands of frames, the labor hours represent a significant operational cost and a major constraint on growth.

How the Machine Provides a Solution

A frame assembly machine systemizes every step of the process, removing variability and dramatically increasing output. It is a tool for achieving predictable quality at a high volume.

Perfect Positioning, Every Time

The machine acts as a jig, holding the wooden frame and the wax foundation sheet in a precise, predetermined alignment. This completely eliminates guesswork and ensures the foundation is perfectly centered.

Uniform and Secure Embedding

The primary mechanical function is to ensure a consistent bond between the frame's wires and the wax. It applies a uniform method—often an electrical current—to heat the wires just enough to melt them a specific depth into the wax sheet, creating a strong and durable attachment across the entire frame.

A Leap in Productivity

What takes minutes to do by hand can be accomplished in seconds with a machine. This leap in efficiency allows a beekeeper to prepare a large inventory of high-quality frames quickly, freeing up valuable time for other critical apiary tasks.

Understanding the Trade-offs

While powerful, this level of automation is not the right solution for every beekeeper. Objectively weighing the costs and benefits is essential.

Significant Initial Investment

These machines represent a notable capital expense. Their cost is a clear indicator that they are designed for serious, high-volume beekeeping operations where the return on investment can be justified by labor savings.

Not Designed for the Small-Scale Hobbyist

For a beekeeper managing a handful of hives, the efficiency gains do not outweigh the cost. The time spent on manual preparation is minimal at that scale, making a frame assembly machine an unnecessary expense.

Requires Space and Power

This is a piece of workshop equipment. It requires a dedicated space to operate and a reliable power source, which are practical considerations for any apiary's workflow.

Is a Frame Assembly Machine Right for You?

The decision to invest in this technology should be driven entirely by the scale and goals of your beekeeping operation.

- If your primary focus is commercial production or large-scale expansion: This machine is a fundamental tool for controlling labor costs and ensuring consistent quality in your hive components.

- If your primary focus is a rapidly growing sideline operation: Consider it a strategic future investment for when manual frame preparation becomes a clear bottleneck to your growth.

- If your primary focus is hobbyist beekeeping with a few hives: Manual methods are far more economical and perfectly sufficient for your needs.

Ultimately, a frame assembly machine transforms the essential task of frame preparation from a logistical challenge into a streamlined, strategic advantage.

Summary Table:

| Function | Benefit |

|---|---|

| Automated Embedding | Replaces slow, manual labor with high-speed, uniform assembly. |

| Perfect Positioning | Ensures every wax foundation sheet is centered and aligned correctly. |

| Secure Bonding | Uses controlled heat to embed wires into wax for a durable, sag-proof frame. |

| Scalable Production | Allows a single operator to prepare hundreds of frames in a fraction of the time. |

Ready to transform your frame preparation process?

For commercial apiaries and beekeeping equipment distributors, manual frame assembly is a major bottleneck. HONESTBEE's wholesale-focused frame assembly machines are engineered to eliminate this inefficiency, providing the industrial-level precision and speed you need to scale your operation and control labor costs.

Contact HONESTBEE today to discuss how our equipment can become a strategic advantage for your business.

Visual Guide

Related Products

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Professional Pneumatic Wire Embedder for Beehive Frames

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

People Also Ask

- How should Frame Grips be maintained after use? A Guide to Biosecurity and Tool Longevity

- What are the primary considerations when selecting a storage location for beekeeping tools and machinery? Expert Guide

- What are the environmental requirements for conducting a hive inspection? Guidelines for Late Winter & Early Spring

- What is required to be a beekeeper? Essential Equipment, Knowledge & Mindset

- Why use Langstroth frame measuring tools with wire grids? Achieve Scientific Accuracy in Brood Assessment