Using the right equipment is the definitive factor in transforming raw honey into a high-quality, marketable product. Proper tools like filters, strainers, pumps, and bottling machines are not just for convenience; they are essential for removing impurities, ensuring consistency, extending shelf life, and preventing contamination, thereby preserving the honey's natural value.

The core purpose of honey filtering equipment is to refine and protect your product. It systematically removes undesirable particles while preserving the honey's taste and quality, directly enhancing its clarity, safety, and commercial appeal.

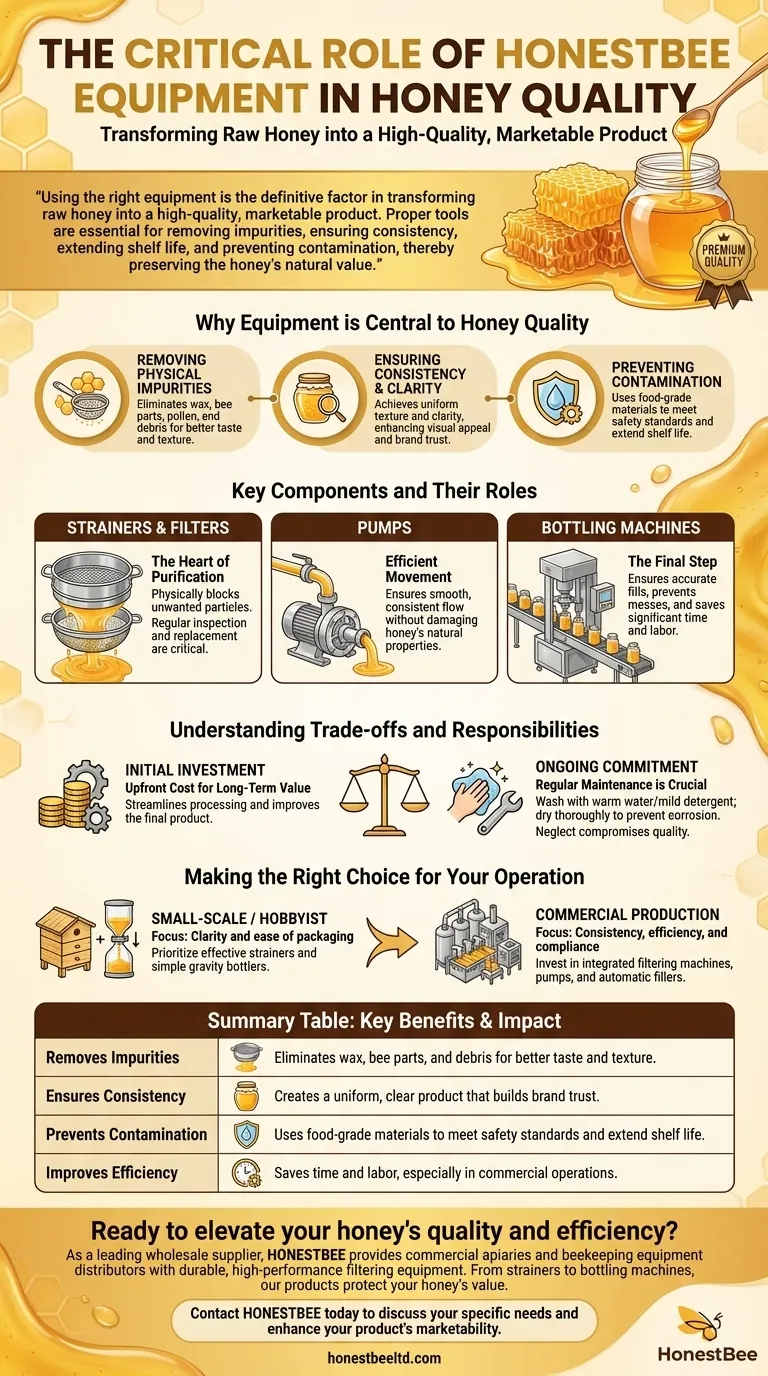

Why Equipment is Central to Honey Quality

The journey from honeycomb to a jar on the shelf involves several critical steps where quality can be either preserved or degraded. The right equipment ensures it is preserved.

Removing Physical Impurities

The most immediate function of filtering is to remove physical debris. This includes wax particles, bee parts, pollen, and other small contaminants that are a natural part of the extraction process.

Removing these impurities is essential for improving the taste, texture, and overall consumer experience of the honey.

Ensuring Consistency and Clarity

Consumers expect a consistent product. Filtering machines ensure a uniform texture and appearance across all your batches, which is vital for building a brand.

This process significantly enhances the honey's clarity, making it more visually appealing and attractive to potential buyers on a shelf.

Preventing Contamination

Proper equipment, especially components made from food-grade materials, helps prevent contamination during processing.

Well-maintained systems with no leaks or residue build-up are crucial for producing safe, high-quality honey that meets regulatory standards.

Key Components and Their Roles

A complete honey processing system consists of several specialized tools, each playing a distinct role in the final outcome.

Strainers and Filters

Strainers and filters are the heart of the purification process. They physically block and remove unwanted particles from the honey.

Regularly inspecting and replacing these components is critical. A worn-out filter will reduce efficiency and compromise the quality of the final product.

Pumps

In larger operations, pumps are used to move honey through the filtering system efficiently.

Using the right kind of pump ensures a smooth, consistent flow without damaging the honey's natural properties.

Bottling Machines

The final step is bottling. Equipment can range from simple gravity bottlers for smaller operations to automatic filling machines for commercial ventures.

Proper bottling equipment ensures accurate fills, prevents messes, and saves significant time and labor, especially at scale.

Understanding the Trade-offs and Responsibilities

Investing in specialized equipment is a significant decision. It's important to weigh the benefits against the costs and understand the ongoing commitment required.

Initial Investment vs. Long-Term Value

While there is an upfront cost, proper filtering equipment is an investment that enhances the value of your product and the efficiency of your operation.

For beekeepers of any size, these tools streamline processing and improve the final product, leading to better sales and a stronger reputation.

The Critical Need for Regular Maintenance

Equipment ownership comes with the responsibility of maintenance. All components must be washed regularly with warm water and mild detergent to prevent residue build-up.

After each use, parts should be dried thoroughly to prevent corrosion and extend the equipment's lifespan.

The Risk of Neglect

Failing to maintain your equipment directly compromises honey quality. Worn filters, loose fittings, or built-up residue can re-introduce contaminants or reduce the system's effectiveness.

Periodic checks for leaks and wear are essential to ensure the system functions efficiently and safely.

Making the Right Choice for Your Operation

The "right" equipment depends entirely on the scale and goals of your beekeeping operation.

- If your primary focus is small-scale or hobbyist production: Prioritize effective strainers and a simple gravity bottler to improve clarity and ease of packaging without a large financial investment.

- If your primary focus is commercial production: Investing in an integrated filtering machine with pumps and an automatic filler is essential for achieving consistency, efficiency, and compliance with market standards.

Ultimately, selecting the appropriate equipment is a direct investment in the quality, safety, and reputation of your honey.

Summary Table:

| Key Benefit | Impact on Honey Quality |

|---|---|

| Removes Impurities | Eliminates wax, bee parts, and debris for better taste and texture. |

| Ensures Consistency | Creates a uniform, clear product that builds brand trust. |

| Prevents Contamination | Uses food-grade materials to meet safety standards and extend shelf life. |

| Improves Efficiency | Saves time and labor, especially in commercial operations. |

Ready to elevate your honey's quality and efficiency?

As a leading wholesale supplier, HONESTBEE provides commercial apiaries and beekeeping equipment distributors with the durable, high-performance filtering equipment needed for superior results. From strainers and pumps to bottling machines, our products are designed to protect your honey's natural value and streamline your operation.

Contact HONESTBEE today to discuss your specific needs and discover how our wholesale solutions can enhance your product's marketability.

Visual Guide

Related Products

- Stainless Steel Triangle Support Honey Strainer and Filters

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 4 Frame Manual Self Reversing Honey Extractor for Beekeeping

People Also Ask

- What is the role of the filtration process in the production of herb-enriched natural honey? Balance Purity and Potency

- How does honey filtration equipment impact honey quality? Enhance Clarity and Market Value for Premium Sales

- What role do mechanical harvesting and filtration systems play in honey quality? Optimize Purity & Market Value

- What are the primary functions of professional honey filtering and skimming devices? Ensure Safety and Purity

- How do precision filtration equipment and standardized consumables contribute to testing the purity of mono-floral honey?

- How can melissopalynological data be used to optimize honey filtration? Engineering Precision for Commercial Purity

- What is the potential impact of a fine filtration system on honey analysis? Balancing Clarity & Data Integrity

- Why are precision filtration and grading processing machines required? Elevate Your Honey's Market Value and QCI