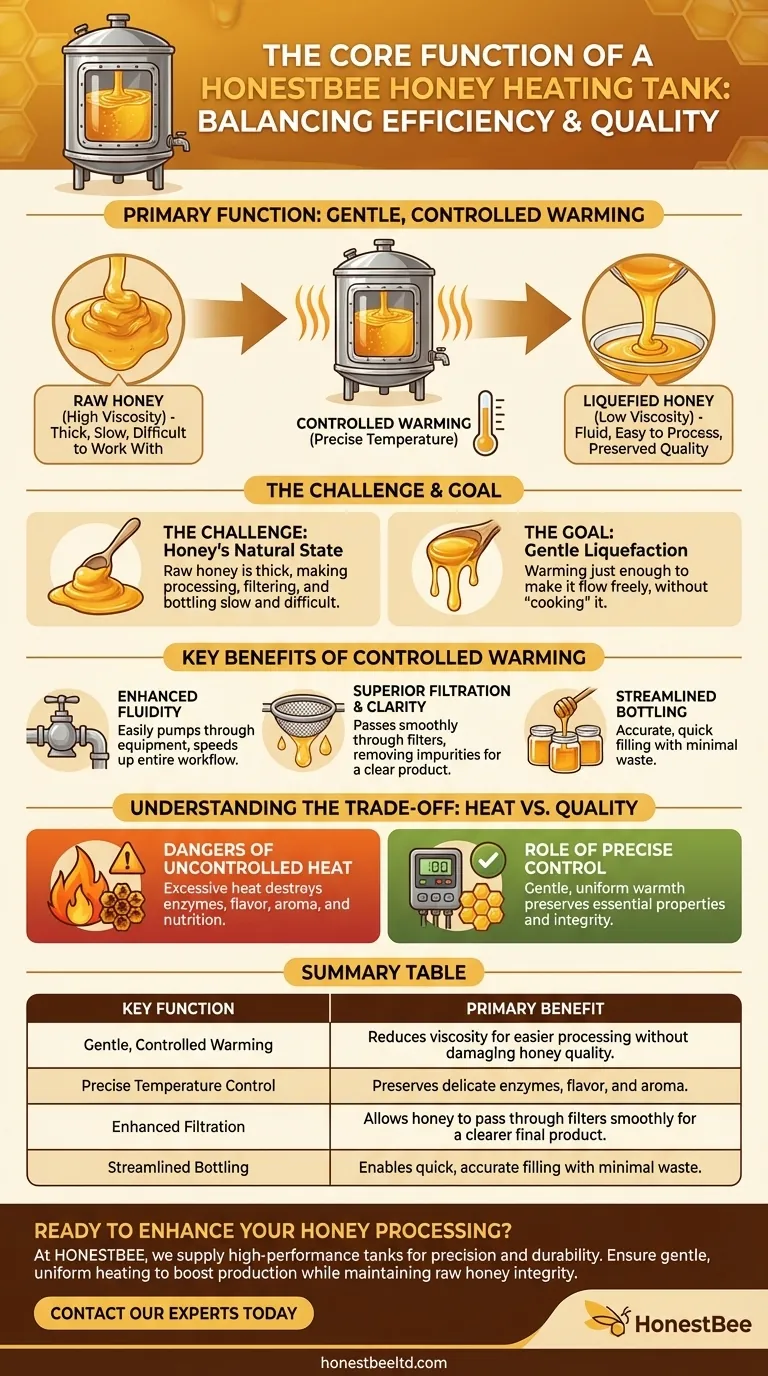

At its core, a honey heating tank is a specialized piece of equipment designed to gently and precisely warm honey. This controlled heating reduces the honey's natural thickness, or viscosity, making it significantly more fluid and easier to process, filter, and bottle without damaging its delicate natural qualities.

The true function of a honey heating tank isn't just to apply heat, but to provide controlled warmth. This precise control is the key to improving honey's workability while meticulously preserving the enzymes, flavor, and aroma that define its quality.

The Core Challenge: Honey's Natural State

Why Raw Honey is Difficult to Work With

Raw honey is naturally thick and viscous, especially at cooler ambient temperatures. This high viscosity makes it slow to move through pipes, difficult to strain effectively, and challenging to pour accurately into containers.

The Goal: Gentle Liquefaction

The objective is never to "cook" the honey. Instead, the goal is liquefaction—gently warming the honey just enough to make it flow more freely, similar to a liquid, for a temporary period.

Key Benefits of Controlled Warming

Enhanced Fluidity for Processing

Warmed honey can be easily pumped through pipes and moved between different stages of production. This simple change reduces strain on equipment and significantly speeds up the entire workflow.

Superior Filtration and Clarity

Reduced viscosity allows honey to pass through filters much more smoothly and efficiently. This ensures the effective removal of impurities such as wax particles or other debris, resulting in a clearer, more appealing final product.

Streamlined Bottling

Fluid honey can be bottled quickly and with greater accuracy. This process minimizes product waste and ensures consistent, professional-looking fill levels in every jar.

Understanding the Trade-off: Heat vs. Quality

The Dangers of Uncontrolled Heat

Applying excessive or uneven heat is detrimental to honey. It can destroy the delicate enzymes and beneficial compounds, permanently altering the honey's natural flavor, aroma, and nutritional value.

The Role of Precise Temperature Control

A quality honey heating tank provides gentle, uniform, and precisely controlled warmth. This sophisticated control is the most critical feature, ensuring the honey is warmed just enough to become workable without degrading its essential properties.

Preserving Honey's Natural Integrity

Ultimately, the purpose of a heating tank is to maintain the honey's complete profile. It is a tool designed specifically to navigate the fine balance between process efficiency and product preservation.

The Impact on Operational Efficiency

Accelerating the Entire Workflow

By making honey easier to handle at every step, a heating tank significantly reduces overall processing time. Operations from extraction to final packaging become faster, more predictable, and more productive.

Enabling Continuous Operation

Many tanks are engineered to support a steady, continuous workflow. This is invaluable for both small-scale and commercial beekeepers who need to process large volumes without interruption.

Is a Heating Tank Right for Your Operation?

Choosing to invest in a honey heating tank depends entirely on your production goals and scale.

- If your primary focus is small-batch hobbyist production: A dedicated heating tank offers superior consistency, though careful, low-tech warming methods can suffice.

- If your primary focus is growing or commercial-scale processing: A heating tank is an essential investment for achieving efficiency, product consistency, and scalability.

- If your primary focus is premium, raw honey quality: Select a tank with highly precise, low-temperature controls to guarantee the preservation of the honey's full nutritional and sensory profile.

A honey heating tank gives you the control necessary to master your process and protect the integrity of your final product.

Summary Table:

| Key Function | Primary Benefit |

|---|---|

| Gentle, Controlled Warming | Reduces viscosity for easier processing without damaging honey quality. |

| Precise Temperature Control | Preserves delicate enzymes, flavor, and aroma. |

| Enhanced Filtration | Allows honey to pass through filters smoothly for a clearer final product. |

| Streamlined Bottling | Enables quick, accurate filling with minimal waste. |

| Operational Efficiency | Speeds up the entire workflow from extraction to packaging. |

Ready to enhance your honey processing efficiency and protect your product's quality?

At HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with high-performance honey heating tanks designed for precision and durability. Our equipment ensures gentle, uniform heating to maintain the integrity of your raw honey while significantly boosting your production speed.

Contact our experts today to find the perfect heating solution for your operation's scale and quality standards.

Visual Guide

Related Products

- Stainless Steel Heated Honey Tank Warming Heating Tank

- Professional Honey Storage Tank with Agitation System

- Stainless Steel Uncapping Tank with Stand and Strainer

- Stainless Steel Honey Storage and Settling Tank with Double Strainer

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

People Also Ask

- How can you keep honey in liquid form and prevent crystallization? Master the Gentle Art of Honey Storage

- What is the role of heating in honey processing? Balance Efficiency and Quality in Your Production

- What factors should be considered when selecting a heater for honey containers? Optimize Your Warming Efficiency

- What is the role of industrial thermochemical heating equipment in the caramelization process of honey? Optimize Quality

- What is the optimal temperature for honey crystallization? Control Texture for Liquid or Creamed Honey

- What role do infrared heating lamp arrays play in beehive experiments? Elevate Hive Thermal Testing Precision

- How does industrial-grade temperature-controlled processing equipment help meet consumer preferences for honey viscosity?

- Why is controlled pre-heating and decrystallization necessary for crystallized honey? Ensure Accurate Diastase Testing