Using a steam wax melter is a straightforward process that leverages hot steam to efficiently render beeswax from old honeycomb. The core procedure involves loading frames into the melter, heating water in a separate generator to create steam, and piping that steam into the melter. The high temperature melts the wax, which then drains through a filter and is collected in a clean container.

The fundamental challenge in rendering beeswax is separating it from old comb and impurities without damaging its quality. A steam wax melter solves this by using the clean, penetrating heat of steam to melt wax quickly and efficiently, ensuring a high-quality, unburnt final product.

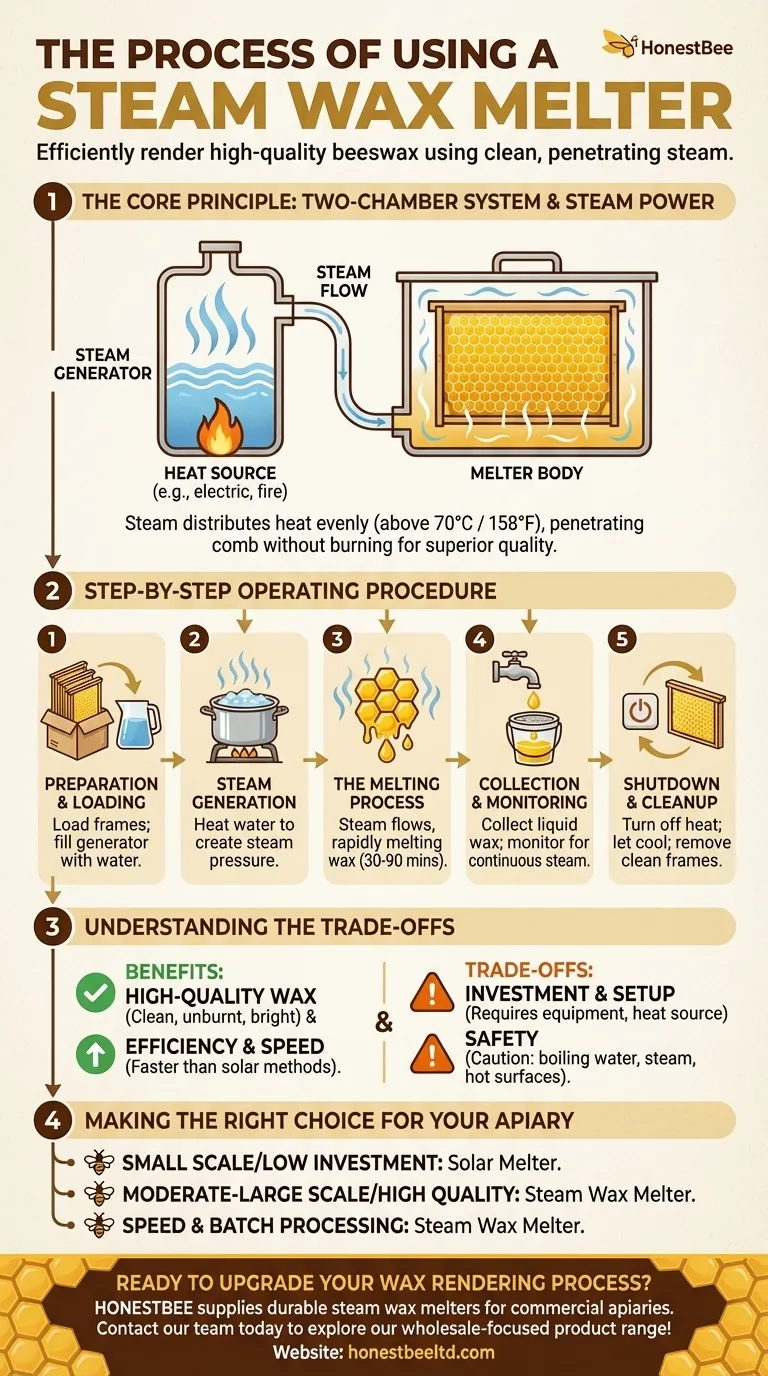

How a Steam Wax Melter Works: The Core Principle

A steam wax melter operates on the simple principle of heat transfer. It is designed to heat honeycomb to a temperature above 70°C (158°F), the melting point of beeswax, using steam as the medium.

The Two-Chamber System

The setup consists of two primary components: a steam generator and the melter body. The generator is a sealed container where water is boiled to produce steam. This steam then travels through a hose into the melter, which houses the frames of honeycomb.

Harnessing the Power of Steam

Steam provides a significant advantage over direct heat. It distributes heat evenly and quickly throughout the chamber, penetrating the comb and ensuring all the wax melts without scorching or burning. This preserves the wax's natural color and quality.

Separation and Filtration

As the wax melts, it drips down from the old comb structure. The remaining debris, often called slumgum, is left behind on the frames. Most melters include a filter mesh or a sloped collection pan that allows the pure, liquid wax to separate and flow toward an outlet tap.

The Step-by-Step Operating Procedure

While specific models vary, the operational process follows a consistent sequence.

Step 1: Preparation and Loading

First, fill the steam generator with water, typically to about half its capacity, to leave room for steam to form. Place your frames, full of old honeycomb, into the basket or rack inside the main melter body.

Step 2: Generating Steam

Begin heating the water in the steam generator. Depending on the design, this is done with an external heat source like a fire or a built-in electric heating element. As the water boils, pressure builds, and steam is created.

Step 3: The Melting Process

The generated steam flows through the connecting hose and fills the melter chamber. The high temperature rapidly melts the wax from the combs. This process can take anywhere from 30 to 90 minutes, depending on the volume of wax and the efficiency of your unit.

Step 4: Collection and Monitoring

Position a clean, heat-proof container beneath the melter’s drain tap to collect the liquid beeswax as it flows out. It is wise to monitor the temperature and ensure a steady production of steam for optimal, continuous melting.

Step 5: Shutdown and Cleanup

Once the flow of wax has stopped, you can turn off the heat source. Allow the unit to cool before carefully opening it and removing the now-clean frames. The collected wax will solidify in its container as it cools.

Understanding the Trade-offs

A steam wax melter is a highly effective tool, but it's important to understand its position relative to other methods.

Key Benefit: High-Quality Wax

The single greatest advantage is the quality of the rendered wax. By avoiding direct, high-temperature flames, steam melting prevents discoloration and burning, yielding a clean, bright, and valuable product.

Key Benefit: Efficiency and Speed

Steam transfers heat exceptionally well, making the entire process significantly faster than passive methods like solar wax melters. This allows a beekeeper to process a large number of frames in a single session.

The Primary Trade-off: Investment and Setup

Unlike a simple solar melter, a steam melter is a more significant piece of equipment. It requires an initial purchase, a dedicated heat source, and a safe area for operation.

A Note on Safety

Operating a steam wax melter requires caution. You are working with boiling water, pressurized steam, and hot surfaces. Always wear appropriate protective gear and handle components carefully to avoid burns.

Making the Right Choice for Your Apiary

Deciding on a wax rendering method depends entirely on the scale of your operation and your primary goals.

- If your primary focus is processing a small number of frames with minimal investment: A simple solar wax melter might be a more suitable starting point.

- If your primary focus is achieving the highest quality wax from a moderate to large apiary: The efficiency and superior results of a steam wax melter make it the ideal choice.

- If your primary focus is speed and batch processing: A steam melter provides a reliable and fast turnaround, allowing you to render large quantities of wax consistently.

By understanding its principles of operation, you can confidently transform old honeycomb into a valuable, pure resource for your beekeeping endeavors.

Summary Table:

| Step | Key Action | Outcome |

|---|---|---|

| 1. Preparation | Load frames into melter; fill generator with water. | Unit is ready for operation. |

| 2. Steam Generation | Heat water to create steam. | Steam is produced for melting. |

| 3. Melting | Steam flows into chamber, melting wax. | Wax melts evenly and drains. |

| 4. Collection | Liquid wax flows through filter into container. | Pure, clean beeswax is collected. |

| 5. Cleanup | Allow unit to cool; remove clean frames. | Process is complete; frames are ready for reuse. |

Ready to upgrade your wax rendering process? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, durable steam wax melters designed for efficiency and superior results. Our wholesale-focused operations ensure you get the reliable equipment you need to produce pristine beeswax at scale. Contact our team today to discuss your needs and explore our product range!

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

People Also Ask

- What precautions should be taken during the milling of wax sheets? A Guide to Producing Flawless Foundation

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- What additional preparation is needed for the work area when making beeswax sheets? Set Up a Professional Production Line

- Why is the precise hexagonal geometry of the rollers critical? Master Beeswax Foundation Quality for Higher Yields

- How does the beeswax flatting and embossing machine prepare the wax for processing? Achieve Perfectly Uniform Wax Sheets