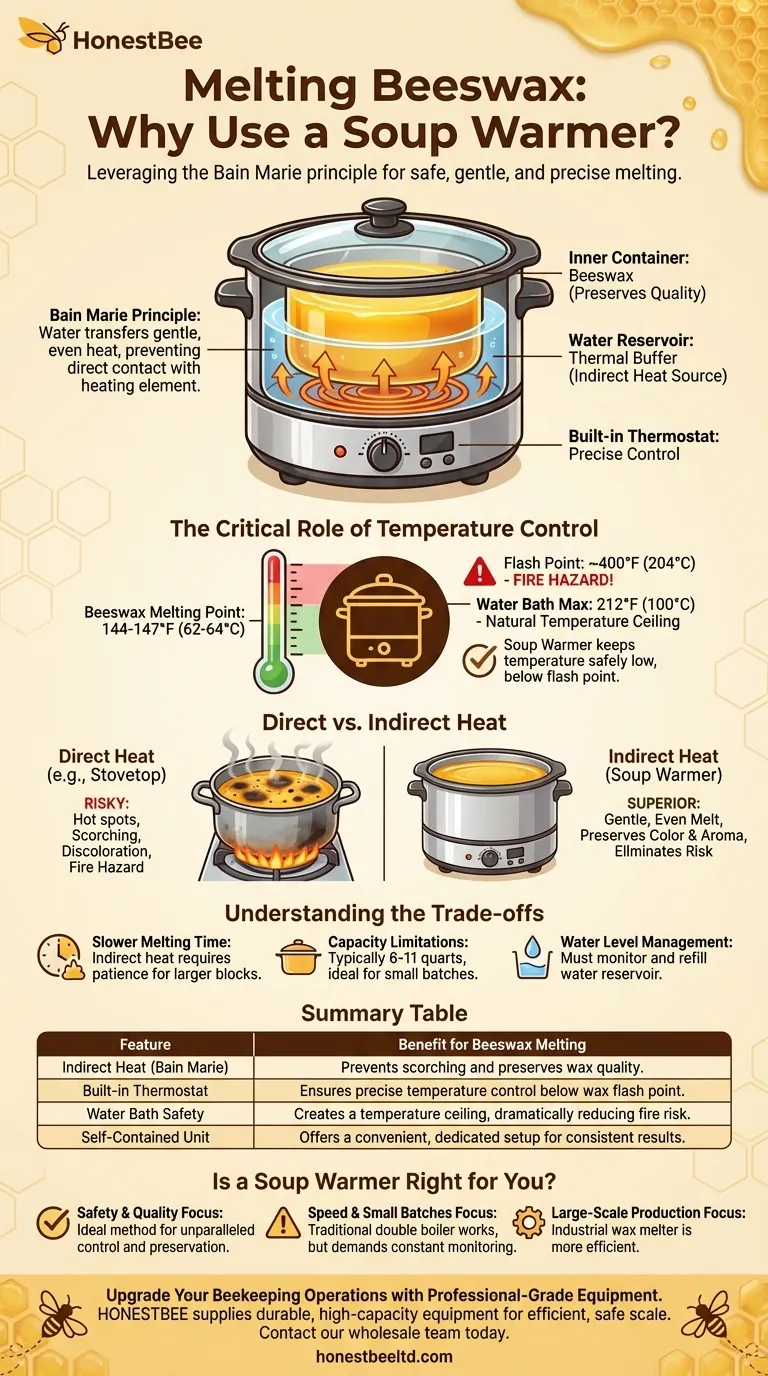

The primary purpose of using a soup warmer to melt beeswax is to leverage its design as a self-contained double boiler, or bain marie. This method uses a reservoir of heated water to provide gentle, indirect heat to an inner container of wax. This ensures precise temperature control, prevents the wax from scorching, and dramatically reduces the risk of fire.

The core principle is simple but critical: separating the beeswax from the direct heat source. A soup warmer achieves this by using water as a thermal buffer, guaranteeing a slow, even melt that preserves the quality of the wax and ensures operational safety.

The Principle of Indirect Heat: Why It Matters

Using direct heat on a stovetop is a common but risky way to melt beeswax. A soup warmer provides a far superior method by applying the principle of indirect heat.

What is a Bain Marie?

A bain marie, or double boiler, is a classic technique where a container is placed inside a larger pot of hot water. The water, not a direct flame or heating element, transfers heat to the inner container.

A soup warmer is simply an electric, thermostatically controlled version of this professional setup. It offers the same benefits with added convenience and precision.

Preventing Scorching and Discoloration

Beeswax is a delicate material. When exposed to direct heat, "hot spots" can easily form on the bottom of the pot, causing the wax to burn.

This scorching not only ruins the wax's beautiful natural color and aroma but can also introduce impurities into your final product. The gentle heat from a soup warmer's water bath eliminates this risk entirely.

The Critical Role of Temperature Control

Managing temperature isn't just about melting the wax; it's the most important factor for safety and quality.

Understanding Beeswax Properties

Beeswax has a relatively low melting point, typically around 144-147°F (62-64°C). However, its flash point—the temperature at which its vapors can ignite—is much higher, around 400°F (204°C).

The goal is to keep the wax safely melted far below its flash point. A direct flame can easily exceed this temperature, creating a significant fire hazard.

How a Soup Warmer Manages Heat

A soup warmer provides two layers of safety. First, the water in the reservoir acts as a natural temperature regulator. Because water boils at 212°F (100°C), it creates a temperature ceiling well below the wax's flash point.

Second, the appliance's built-in thermostat allows you to set and maintain a consistent water temperature, giving you precise and reliable control over the entire melting process.

Understanding the Trade-offs

While highly effective, this method has considerations you should be aware of.

Slower Melting Time

By its very nature, indirect heat is slower than direct heat. This is a feature for safety and quality, not a bug, but it means melting a large block of wax will require patience.

Capacity Limitations

Most commercial soup warmers are designed for 6 to 11 quarts. This is ideal for hobbyists or small businesses but may not be sufficient for large-scale production.

Water Level Management

During long melting sessions, the water in the reservoir will evaporate. You must monitor the water level and refill it as needed to ensure the unit operates safely and effectively.

Is a Soup Warmer the Right Tool for You?

Choosing your melting method depends entirely on your project's goals for safety, quality, and scale.

- If your primary focus is safety and quality: A soup warmer is the ideal method, providing unparalleled control and preventing damage to the wax.

- If your primary focus is speed for very small batches: A traditional double boiler on a stovetop can work, but it demands constant and vigilant monitoring.

- If your primary focus is large-scale industrial production: A dedicated, purpose-built industrial wax melter is a more efficient and appropriate investment.

Ultimately, using a soup warmer is a professional technique that prioritizes a safe process and a superior final product.

Summary Table:

| Feature | Benefit for Beeswax Melting |

|---|---|

| Indirect Heat (Bain Marie) | Prevents scorching and preserves wax quality. |

| Built-in Thermostat | Ensures precise temperature control below wax flash point. |

| Water Bath Safety | Creates a temperature ceiling, dramatically reducing fire risk. |

| Self-Contained Unit | Offers a convenient, dedicated setup for consistent results. |

Upgrade Your Beekeeping Operations with Professional-Grade Equipment

For commercial apiaries and equipment distributors, precision and safety in wax processing are non-negotiable. HONESTBEE supplies the durable, high-capacity beekeeping equipment you need to operate efficiently and safely at scale.

Let us help you equip your business for success. Contact our wholesale team today to discuss your specific needs and explore our range of reliable supplies.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

People Also Ask

- What type of beeswax should be used for processing? Choose Wax Caps for Pure Results and Colony Health

- How do closed-loop wax and beeswax processing systems contribute to apiary biosafety? Enhance Colony Health & Yield

- How does a solar-powered frame wax melter work? Harness the Sun for Sustainable Beekeeping

- Why is a double boiler considered ideal for rendering beeswax? Expert Guide to Safe & Pure Wax Processing

- Why is it necessary to install discharge valves at different heights on beeswax containers? Optimize Wax Purity

- What is the purpose of the Beeswax purification process? Unlock High-Value Markets for Beekeeping Products

- What role does industrial-grade hydrogen peroxide play in beeswax? Mastering Bleaching for Premium White Beeswax

- What are the safety considerations when melting beeswax? A Guide to Preventing Fires and Burns