At its core, a honey pump is a specialized piece of equipment designed to transfer honey from one point to another—such as from a filter to a storage tank or bottling line. Its primary role is to move this highly viscous fluid efficiently and, most importantly, without damaging its delicate structure, flavor, or aroma.

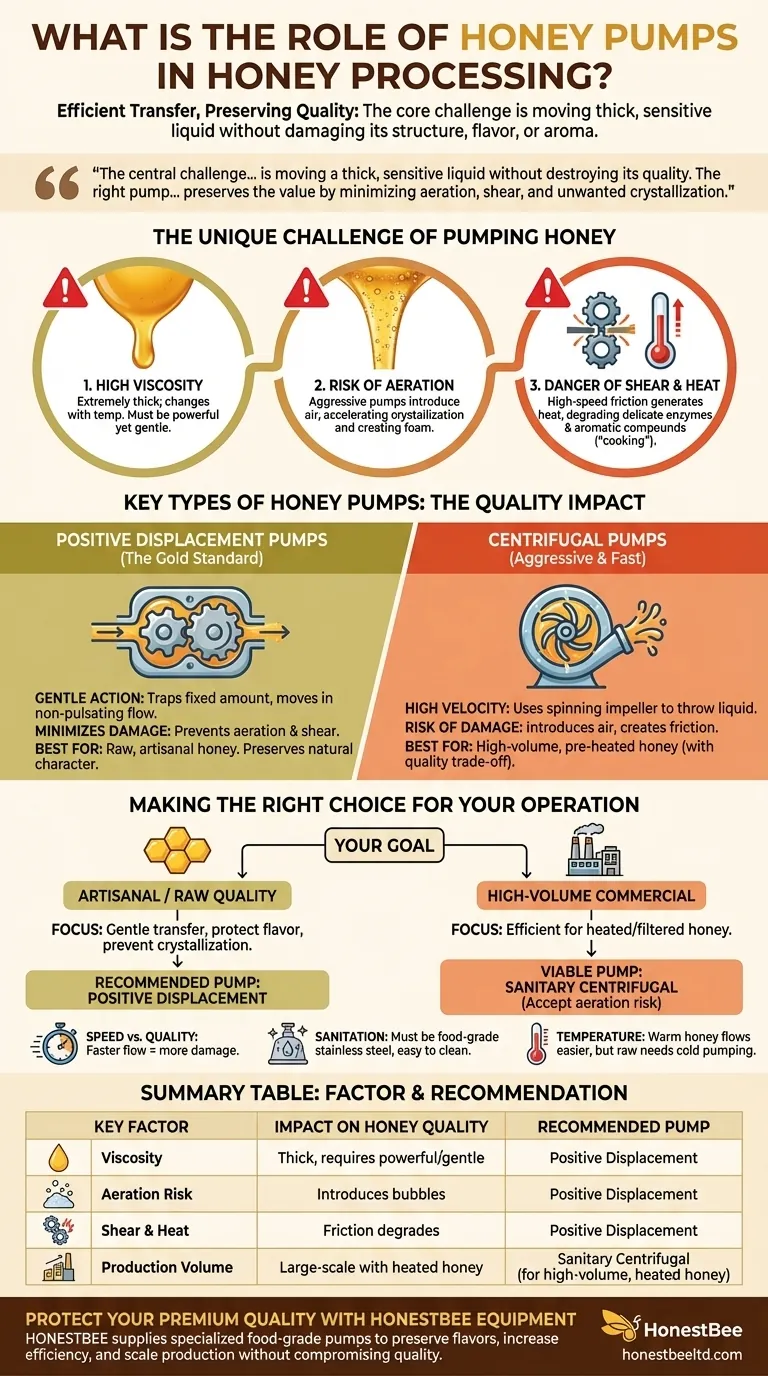

The central challenge in honey processing is moving a thick, sensitive liquid without destroying its quality. The right honey pump isn't just about transfer; it's about preserving the value of the final product by minimizing aeration, shear, and unwanted crystallization.

Why Pumping Honey Is a Unique Challenge

Unlike water or other thin liquids, honey presents specific problems that standard pumps cannot handle. Understanding these challenges is key to appreciating the role of a specialized honey pump.

The Problem of High Viscosity

Honey is extremely thick, and its viscosity changes dramatically with temperature. A pump must be powerful enough to move cold, thick honey without straining but also gentle enough not to damage it.

The Risk of Aeration

Pumps that move too quickly or use aggressive force can whip air into the honey. This introduces countless tiny air bubbles, which can accelerate crystallization and give the final product a foamy, undesirable appearance.

The Danger of Shear and Heat

High-speed pumps, particularly industrial centrifugal models, can create high shear forces. This friction can generate heat, which degrades the delicate enzymes and aromatic compounds in honey, effectively "cooking" it and destroying the qualities that make it unique.

Key Types of Honey Pumps

The choice of pump directly impacts honey quality. The two main categories used in honey processing have distinct advantages and disadvantages.

Positive Displacement Pumps

This is the gold standard for high-quality honey processing. These pumps trap a fixed amount of honey and gently move it through the system in a continuous, non-pulsating flow.

They excel at handling thick, viscous fluids at low speeds. This gentle action prevents aeration and shear, preserving the honey's natural character, making them ideal for raw or artisanal honey producers.

Centrifugal Pumps

Centrifugal pumps use a spinning impeller to throw the liquid outward at high velocity. While highly efficient for moving water, they are generally too aggressive for honey.

Sanitary centrifugal pumps are a subtype sometimes used in large commercial operations where honey is heated to lower its viscosity. However, the risk of introducing air and creating friction remains, making them less suitable for premium, unheated honey.

Understanding the Trade-offs

Choosing a pump involves balancing speed, cost, and the final quality of your honey. There is no single "best" pump without first defining your goals.

Speed vs. Quality

Pushing honey through a system too quickly is the most common mistake. A faster flow rate almost always leads to more aeration and shear damage. A slower, more controlled transfer with a positive displacement pump protects the honey's integrity.

Pump Material and Sanitation

Any equipment touching honey must be made from food-grade materials, typically stainless steel. A "sanitary" pump is designed for easy cleaning, preventing contamination and the buildup of bacteria between batches. This is a non-negotiable requirement.

The Impact of Temperature

Warm honey flows more easily, reducing the strain on the pump. Some large-scale processors gently warm their honey to use faster pumps. However, for "raw" honey producers, the pump must be capable of moving cool, thick honey without requiring any heat.

Making the Right Choice for Your Operation

Your production goals should dictate your equipment choice. A pump is not just a tool for transfer; it is a tool for quality control.

- If your primary focus is preserving artisanal or raw honey quality: A positive displacement pump is the only choice to ensure a gentle transfer that protects delicate flavors and prevents crystallization.

- If your primary focus is high-volume, efficient commercial production: A sanitary centrifugal pump may be viable for pre-heated and filtered honey, but you must accept the potential trade-off in quality due to higher aeration risk.

Ultimately, selecting the right honey pump is a critical decision that reflects your commitment to the quality of your final product.

Summary Table:

| Key Factor | Impact on Honey Quality | Recommended Pump Type |

|---|---|---|

| Viscosity | Thick honey requires powerful, gentle handling | Positive Displacement |

| Aeration Risk | High-speed pumps introduce air bubbles, accelerating crystallization | Positive Displacement |

| Shear & Heat | Friction can degrade enzymes and aromas | Positive Displacement |

| Production Volume | Large-scale operations may use centrifugal pumps with heated honey | Sanitary Centrifugal (for high-volume, heated honey) |

Protect Your Honey's Premium Quality with the Right Equipment

Choosing the correct honey pump is a critical investment in your product's integrity. For commercial apiaries and distributors, the wrong pump can lead to degraded flavor, premature crystallization, and a lower-value final product.

HONESTBEE supplies the specialized beekeeping supplies and equipment you need to succeed. We provide wholesale-focused solutions, including high-quality, food-grade honey pumps designed for gentle, efficient transfer. Our equipment helps you:

- Preserve delicate flavors and aromas by minimizing aeration and shear.

- Increase operational efficiency with reliable, easy-to-clean pumps.

- Scale your production without compromising on honey quality.

Ready to upgrade your honey processing? Contact our experts today to discuss the best pump solution for your commercial or distribution needs.

Visual Guide

Related Products

- Honey Convey Pump Screw Honey Pump for Viscous Liquid

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Professional Honey Filter with Tripod Support Stand

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- How do professional honey processing tools improve industrial efficiency? Boost Your Apiary's Scalability

- How does a stainless steel screw honey pump work? Efficient, Food-Grade Transfer Solutions for Your Apiary

- How does a stainless steel screw honey pump operate? A Guide to Gentle, High-Quality Honey Transfer

- Who are the typical users of stainless steel screw honey pumps? From Commercial Beekeepers to Hobbyists

- What is the process for harvesting honey from a Kenya Top-Bar Hive? Master the Crush and Strain Method