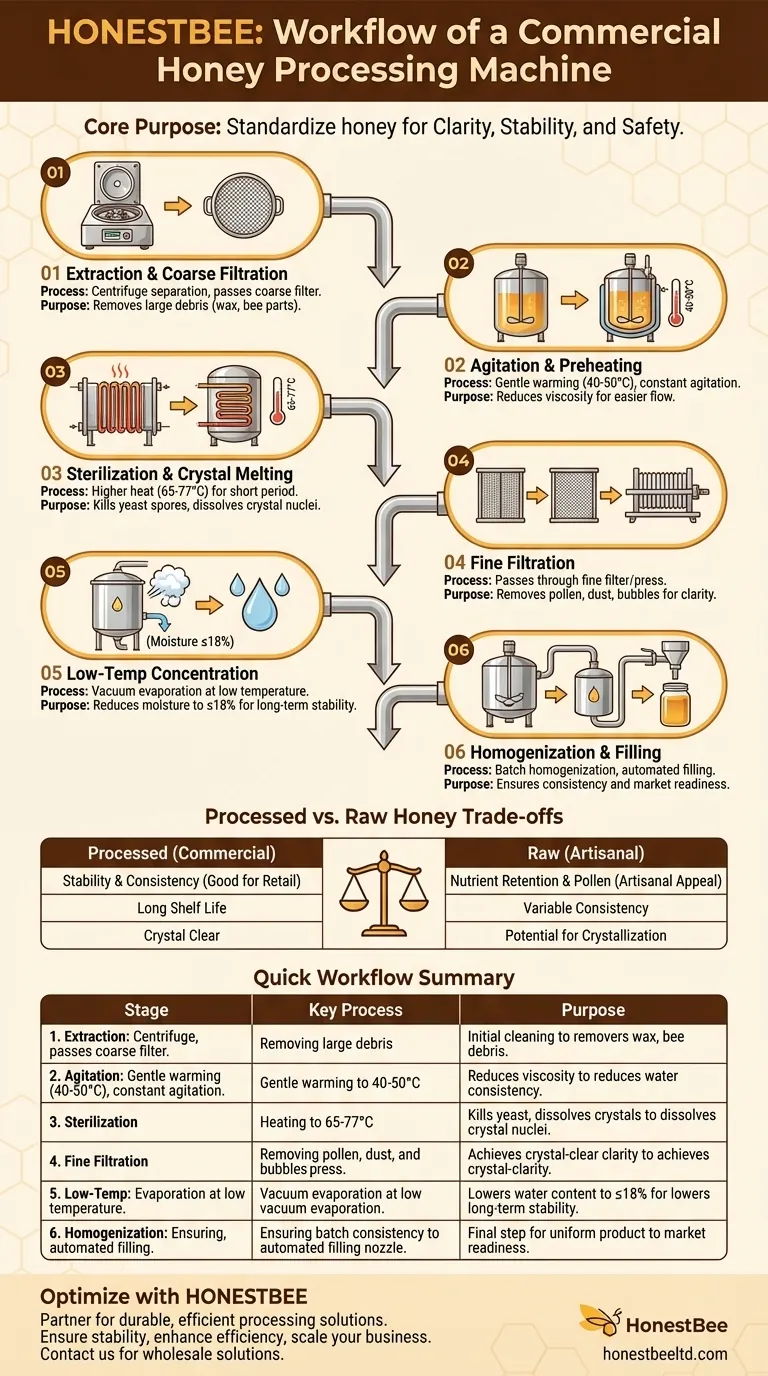

The typical workflow of a honey processing machine involves a series of precise stages designed to refine raw honey into a stable and marketable product. This sequence generally includes coarse filtration, preheating and agitation, fine filtration, sterilization to melt crystal nuclei, low-temperature moisture reduction, and finally, filling. Each step serves a specific purpose in ensuring the honey's quality, clarity, and shelf life.

The core purpose of a honey processing machine is not just to clean the honey, but to standardize it. The workflow is engineered to control three key factors: clarity (removing particles), stability (preventing crystallization), and safety (reducing moisture content to prevent fermentation).

From Raw Comb to Refined Product: The Processing Stages

The journey from raw honey to a jar on the shelf is a multi-step process. While a small-scale beekeeper might simply strain their honey, commercial operations rely on a more controlled, mechanized workflow to guarantee consistency and quality.

Step 1: Extraction and Coarse Filtration

Before processing begins, honey is extracted from the honeycomb, typically using a centrifuge that separates the liquid honey from the wax comb.

This raw honey is then pumped into the processing system and passes through a coarse filter. This initial step removes large, visible debris such as wax particles, bee parts, and other impurities from the hive.

Step 2: Agitation and Preheating

To move forward, the honey must be made less viscous. The honey is gently warmed in a jacketed tank, often to around 40-50°C (104-122°F), while being agitated.

Preheating does not cook the honey; it simply makes it flow more easily for the subsequent filtration and pumping stages. The agitation ensures even heat distribution, preventing any part of the honey from overheating.

Step 3: Sterilization and Melting Crystal Nuclei

This is a critical stage for producing shelf-stable honey. The honey is heated to a higher temperature for a short period, often around 65-77°C (149-170°F).

This process achieves two goals. First, it kills osmotolerant yeast spores that could cause fermentation. Second, it dissolves the fine sugar crystals (crystal nuclei) that act as seeds for crystallization, ensuring the honey remains liquid for longer.

Step 4: Fine Filtration

After heating, the honey passes through a fine filter or press. This step removes much smaller suspended particles, including pollen, dust, and air bubbles.

The result is the crystal-clear, polished honey that consumers expect from most commercial brands.

Step 5: Low-Temperature Concentration

Perhaps the most important step for long-term stability is reducing the water content. Honey with high moisture (over 20%) is prone to fermentation.

Modern machines use low-temperature vacuum concentration. By placing the honey under a vacuum, the boiling point of water is lowered, allowing excess moisture to be evaporated without using high heat that could damage the honey's delicate flavors and enzymes. The goal is to achieve a final moisture content of 18% or less.

Step 6: Homogenization and Filling

Finally, the processed honey is often held in a tank and may be homogenized to ensure consistency across the entire batch. It is then pumped to a filling machine, which accurately dispenses the finished product into jars for sealing and labeling.

Understanding the Trade-offs: Processed vs. Raw Honey

The decision to use a full processing workflow is driven by commercial needs. However, it's essential to understand the trade-offs involved compared to minimally processed or "raw" honey.

The Goal of Processing: Stability and Consistency

Commercial honey processing is designed to create a predictable and reliable product. It prevents crystallization, stops fermentation, and ensures that a jar of honey purchased in July is identical to one purchased in December. This is crucial for large-scale retail.

The Cost of Processing: Potential Nutrient Impact

Heat can be detrimental to some of honey's beneficial compounds. Excessive or prolonged heating can degrade enzymes like diastase and invertase and reduce the complexity of the honey's natural aroma. Modern techniques like vacuum concentration are specifically designed to minimize this thermal impact.

The Impact of Filtration: Clarity vs. Pollen

Fine filtration, which creates exceptional clarity, also removes most of the pollen. While pollen is an impurity from a clarity standpoint, some consumers seek it out for its potential health benefits and as a marker of the honey's floral and geographic origin. Raw or lightly strained honey retains this pollen.

Making the Right Choice for Your Goal

The "best" honey processing method depends entirely on the end goal for the product and the target market.

- If your primary focus is artisanal or small-batch production: Minimal processing, such as simple straining and gentle warming, is often best to preserve the unique character, flavor, and natural components of your honey.

- If your primary focus is commercial retail and long shelf life: The full, controlled workflow of a honey processing machine is necessary to meet quality standards, ensure product stability, and achieve consumer expectations for clarity and consistency.

- If your primary focus is consumer health: Understanding the difference between raw, unfiltered honey (which retains pollen and enzymes) and processed honey (which offers purity and stability) allows you to make an informed choice based on your priorities.

Ultimately, honey processing is a tool used to transform a raw agricultural product into one that is safe, stable, and suitable for its intended market.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| 1. Extraction & Coarse Filtration | Removing large debris (wax, bee parts) | Initial cleaning and impurity removal |

| 2. Agitation & Preheating | Gentle warming to 40-50°C (104-122°F) | Reduces viscosity for easier pumping and filtration |

| 3. Sterilization | Heating to 65-77°C (149-170°F) | Kills yeast spores and dissolves sugar crystals to prevent fermentation and crystallization |

| 4. Fine Filtration | Removing pollen, dust, and air bubbles | Achieves crystal-clear clarity for consumer appeal |

| 5. Low-Temp Concentration | Vacuum evaporation to reduce moisture | Lowers water content to ≤18% to ensure long-term stability |

| 6. Homogenization & Filling | Ensuring batch consistency and packaging | Final step for uniform product quality and market readiness |

Ready to Optimize Your Honey Production Workflow?

Whether you are a commercial apiary scaling up operations or a beekeeping equipment distributor seeking reliable wholesale partners, HONESTBEE has the solutions you need. We supply durable, efficient honey processing machines and beekeeping supplies designed for high-volume, consistent output.

Partner with HONESTBEE to:

- Ensure Product Stability: Achieve the perfect moisture content and clarity to meet commercial standards.

- Enhance Efficiency: Streamline your workflow with equipment built for reliability and ease of use.

- Scale Your Business: Access wholesale-focused equipment and supplies tailored for commercial beekeeping success.

Contact HONESTBEE today to discuss your specific needs and discover how our processing solutions can help you deliver a superior, shelf-stable product to your market.

Visual Guide

Related Products

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Professional Thermostatic Conical Honey Melter

- Automatic Honey Frame Uncapper Machine for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Honey Gate Valve with Ergonomic Ball Handle Plastic Bee Honey Tap for Beekeeping Bottling and Honey Extractor Equipment

People Also Ask

- What makes automated honey extractors adaptable to different beekeeping needs? Precision Tuning for Commercial Success

- What operational benefits do motorized honey extractors provide? Scale Your Harvest Efficiency

- Why are industrial centrifugal honey extractors essential for preserving honeycomb? Boost Your Apiary's Yield Today

- What are the core functions of an industrial 12-frame honey extractor? Boost Efficiency and Hive Resource Conservation

- Is it feasible to use a honey extractor to harvest from foundationless frames? Safely Extract Without Damaging Comb